Recyclable inner-bracing sleeve

A sleeve and plug technology, which is applied in the field of concrete wall pouring, can solve the problems that the sleeve cannot be taken out, cannot be reused, and is not easy to fix, etc., and achieves the effect of convenient removal, increased reuse times, and increased reuse times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment and accompanying drawing, the present invention will be further elaborated:

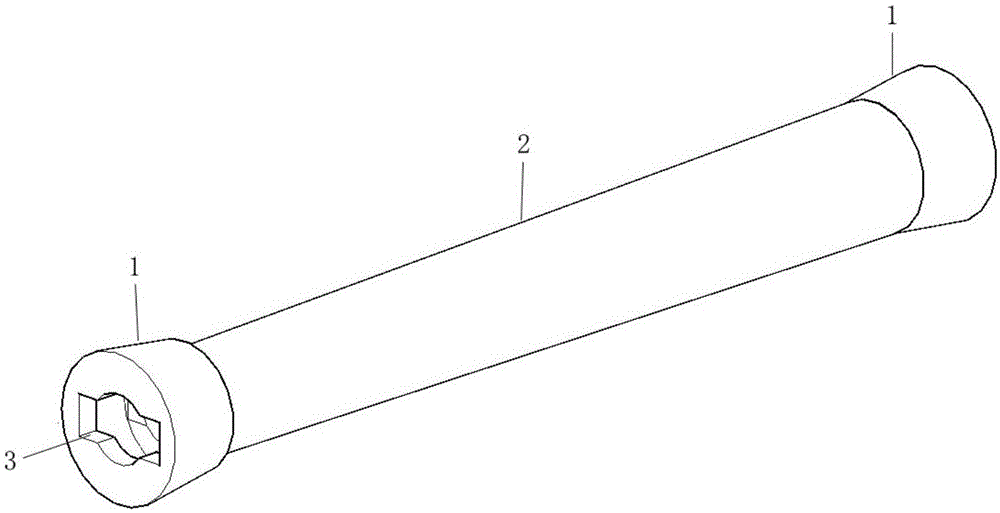

[0029] attached by figure 1 It can be seen that the inner support sleeve includes the inner support sleeve plug head 1 and the inner support sleeve main diameter 2. The inner support sleeve models are diversified, suitable for walls of various widths, different types of inner support sleeves, inner support sleeve plugs The head is universal, and the main diameter of the inner support sleeve is the same. The difference is that the length of the main diameter of the inner support sleeve is different according to the needs of different walls. The inner support casing usually has 150mm, 200mm, 250mm, 300mm, 350mm types; each part is made of rigid PVC material.

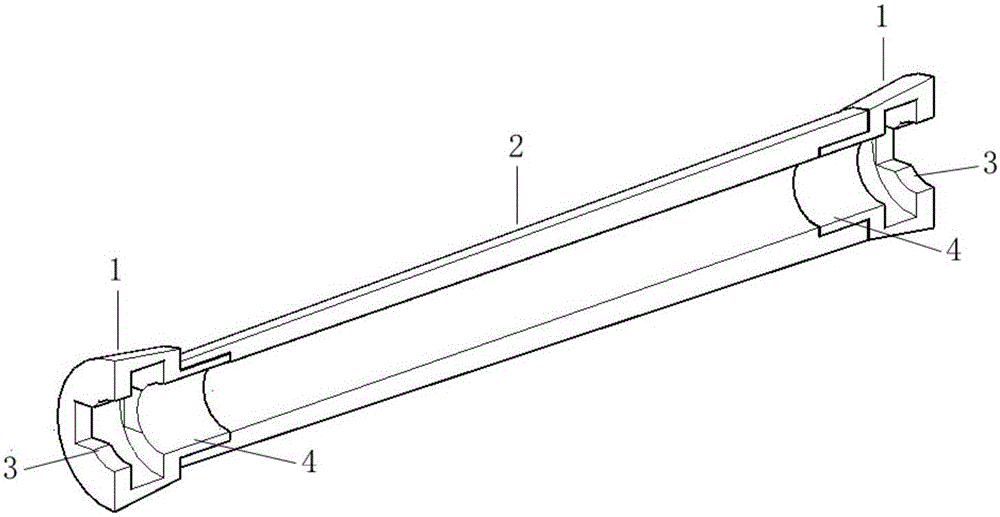

[0030] attached by figure 2 It can be seen that the structure of the inner support sleeve: the inner support sleeve plug 1, the inner support sleeve main diameter 2, the inner support plug key hole 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com