Implementation method of central control platform of underground fully-mechanized coal face hydraulic supports

A fully mechanized mining face and hydraulic support technology, which is applied in mine roof support, mining equipment, earth square drilling and mining, etc., to achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

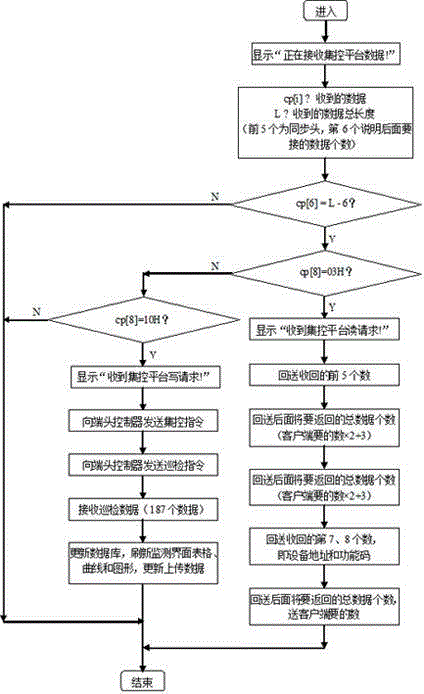

[0028] Attached below figure 1The realization method of the present invention is further described in detail with the specific embodiment. Those skilled in the art, after reading the specific embodiment, utilize the existing hydraulic support explosion-proof computer, end controller, support controller, combined with Siemens PLCS7-300 , C8051F020 single-chip microcomputer, PowerBuilder tool, SQLServer database and multi-protocol communication platform to realize the control method of the hydraulic support centralized control platform of the underground fully mechanized mining face of the present invention, and also can realize the positive effect of the present invention simultaneously.

[0029] The method of the invention adopts the PowerBuilder tool as the front-end development platform, Siemens PLCS7-300, C8051F020 single-chip microcomputer as the real-time control platform, and realizes the centralized control of the hydraulic support of the fully mechanized mining face in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com