Gear-transmission zero-leakage flat gate valve

A technology of gear transmission and slab gate valve, which is applied in the direction of sliding valves, valve devices, engine components, etc., can solve the problems of large installation space, poor sealing reliability, and large valve volume, so as to reduce the volume and weight of the valve, avoid leakage, The effect of improving the sealing performance of the cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

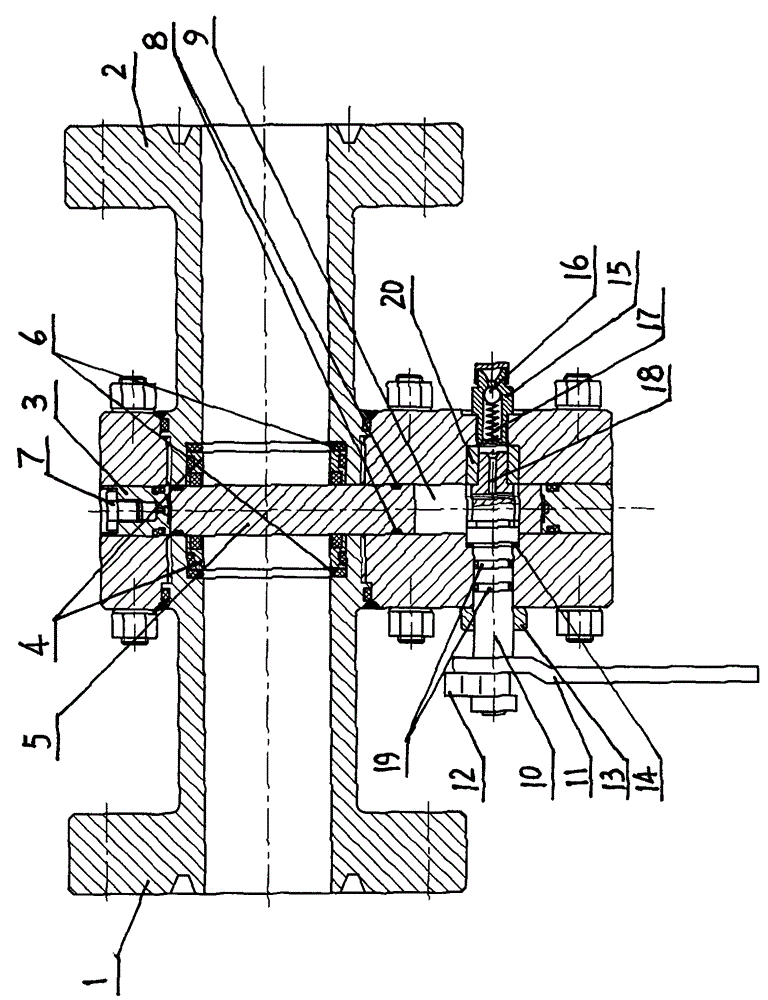

[0012] Such as figure 1 The gear-driven zero-leak flat gate valve shown includes a valve body, a valve seat 4, a gate plate 5, and a handle 11. The valve body is composed of a left valve body 1, a right valve body 2 and a middle valve body 3. The valve seat 4 is installed on In the passage of the left valve body 1 and the right valve body 2, the sealing surface of the valve seat 4 and the sealing surface of the gate plate 5 cooperate to seal each other, and the other end surface of the valve seat 4 and the radial end surface of the left valve body 1 and the right valve body 2 The elastic element 6 is provided to make the valve seat 4 and the gate 5 elastically floating and fit; the outer circular surface of the gate 5 is connected with the circular wall of the inner cavity of the middle valve body 3 in a dynamic fit, and a fan-shaped through hole 9 is made in the plane of the gate 5, and the fan-shaped through A sector gear is made on the inner arc surface of the hole 9, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com