A four-tube tear gas gun

A gun seat and gun handle technology, which is applied in the field of tear gas gun structure, can solve the problems of unreliability, complex tear gas bomb structure, lag behind actual combat needs of police explosion-proof weapons, etc., and achieve the effect of avoiding fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

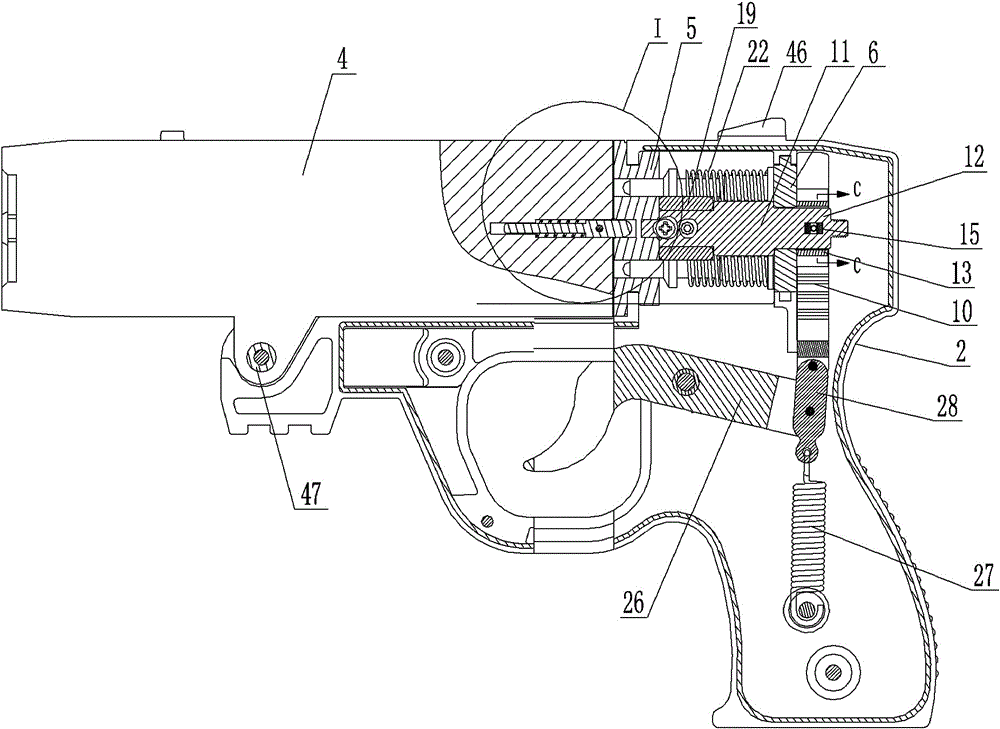

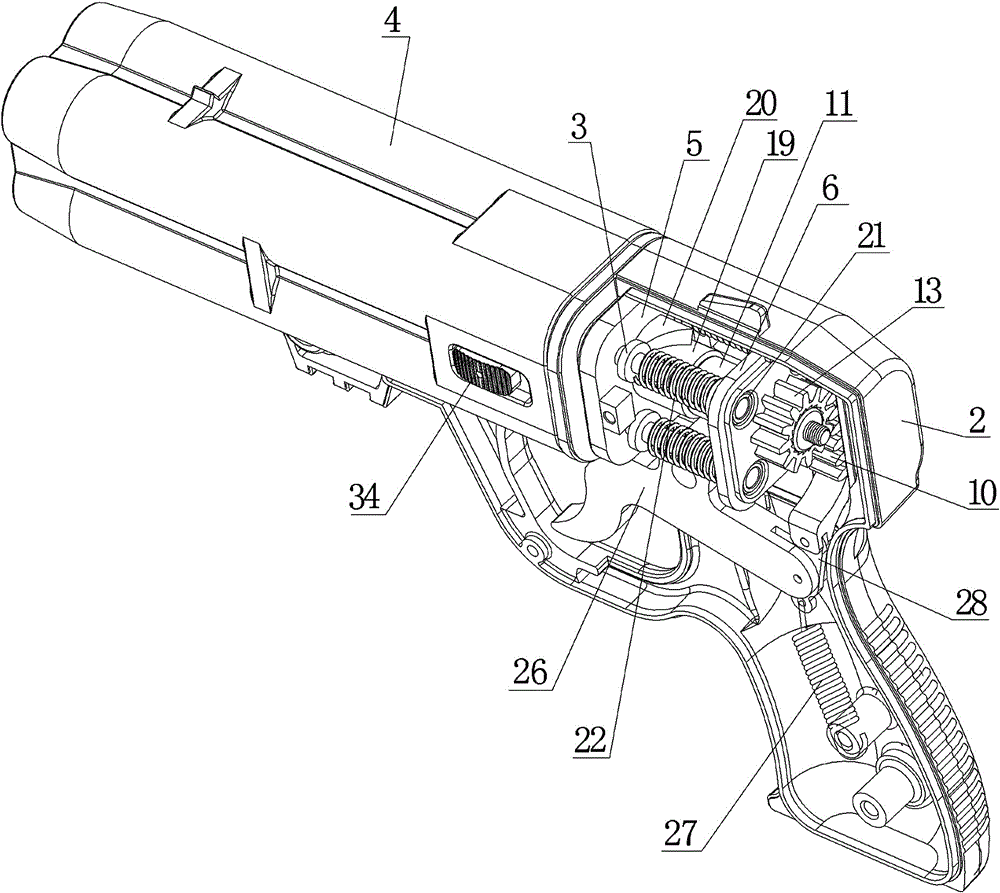

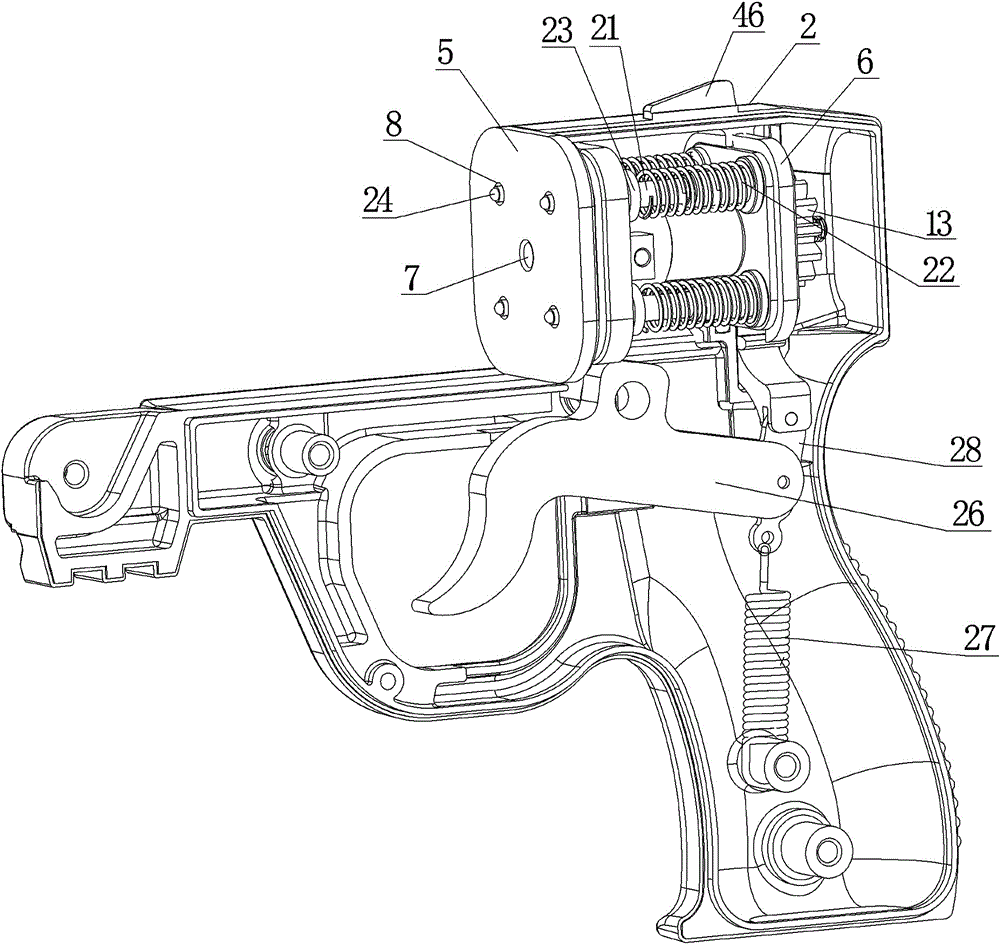

[0044] Such as figure 1 , 2 , 3, 4, 21, 23, and 24, a four-barrel tear gas gun, which includes a left gun seat 1 and a right gun seat 2, a firing pin 3, a clip 4, and a left gun seat 1 and a right gun seat that are engaged with each other. The transmission mechanism between the right gun seat 2, the striker front seat 5 and the striker rear seat 6 between the left gun seat 1 and the upper half of the right gun seat 2, the left end of the striker front seat 5 is provided with a blind hole 7, The right end of striker front seat 5 is provided with four guide holes 8, and four guide holes 8 are evenly distributed with blind hole 7 as the center, and the inboard of described right gun seat 2 is provided with chute 9, and chute 9 is provided with Rack 10 moving along chute 9.

[0045] Such as figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com