An automatic depth-limiting device for a peanut combine harvester

A technology for combine harvesters and peanuts, which is applied to digging harvesters, harvesters, agricultural machinery and implements, etc. It can solve the problems of limited volume, poor representativeness of sampling points, and poor anti-interference performance, so as to improve ranging accuracy, Superior depth-limiting effect and sensitive feedback control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

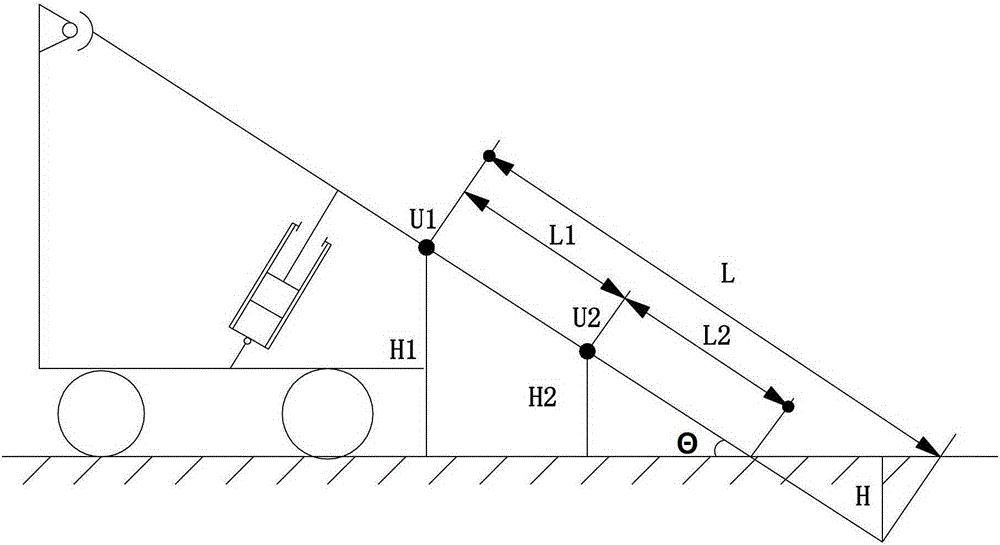

[0036] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

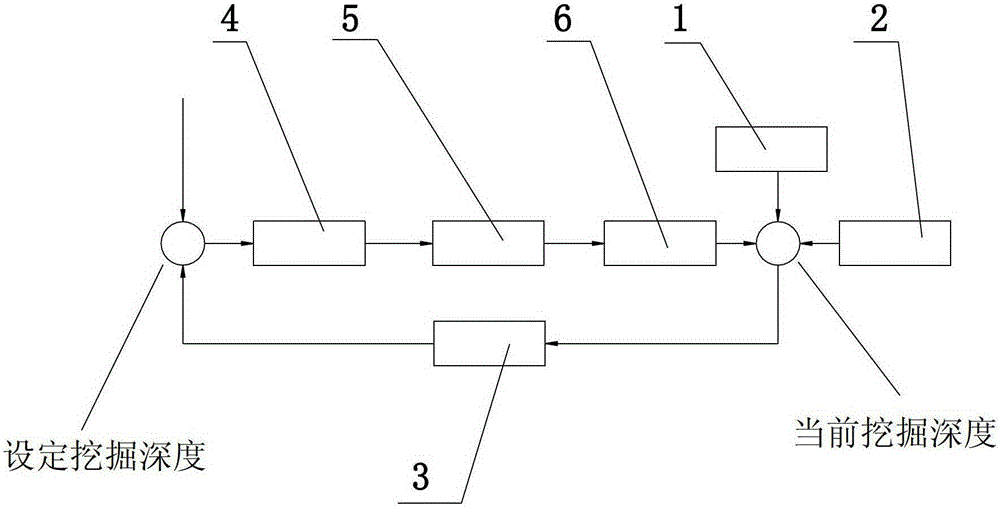

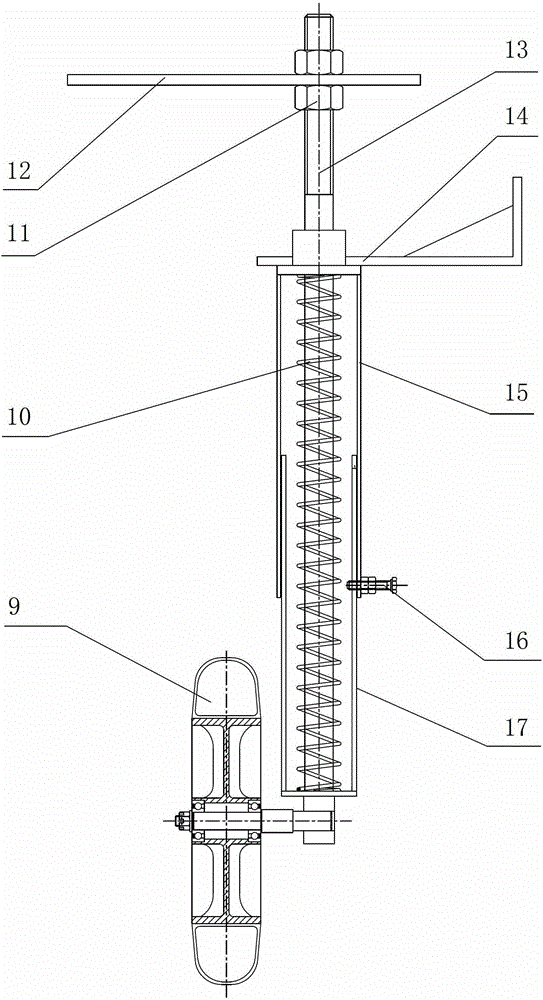

[0037] An automatic depth-limiting device for a peanut combine harvester. A ground profiling device 2 is arranged close to the ground. Above the ground profiling device 2, an ultrasonic sensor 1 is installed on the fender of the peanut combine harvester. The ultrasonic ranging module 3 is aimed at the measurement reference plate 12 on the ground profiling device 2, and the signal collected by the ultrasonic ranging module 3 is sent and fed back to the controller 4 installed in the cab, and the control signal of the controller 4 is sent to the controller installed in the cab. The solenoid valve 5 at the bottom is driven by the hydraulic oil pipe and the double-acting hydraulic cylinder 6 to adjust the digging depth of the excavating shovel;

[0038] The structure of the ground profiling device 2 is as follows: on the wheel shaft of the ground ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com