A kind of organic electroluminescent material and organic electroluminescent device

A technology of electroluminescent devices and light-emitting layers, applied in the fields of light-emitting materials, electro-solid devices, organic chemistry, etc., can solve the problems of unsatisfactory performance of blue-light OLED devices, and achieve excellent electroluminescent performance, high efficiency, improved The effect of the carrier recombination factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

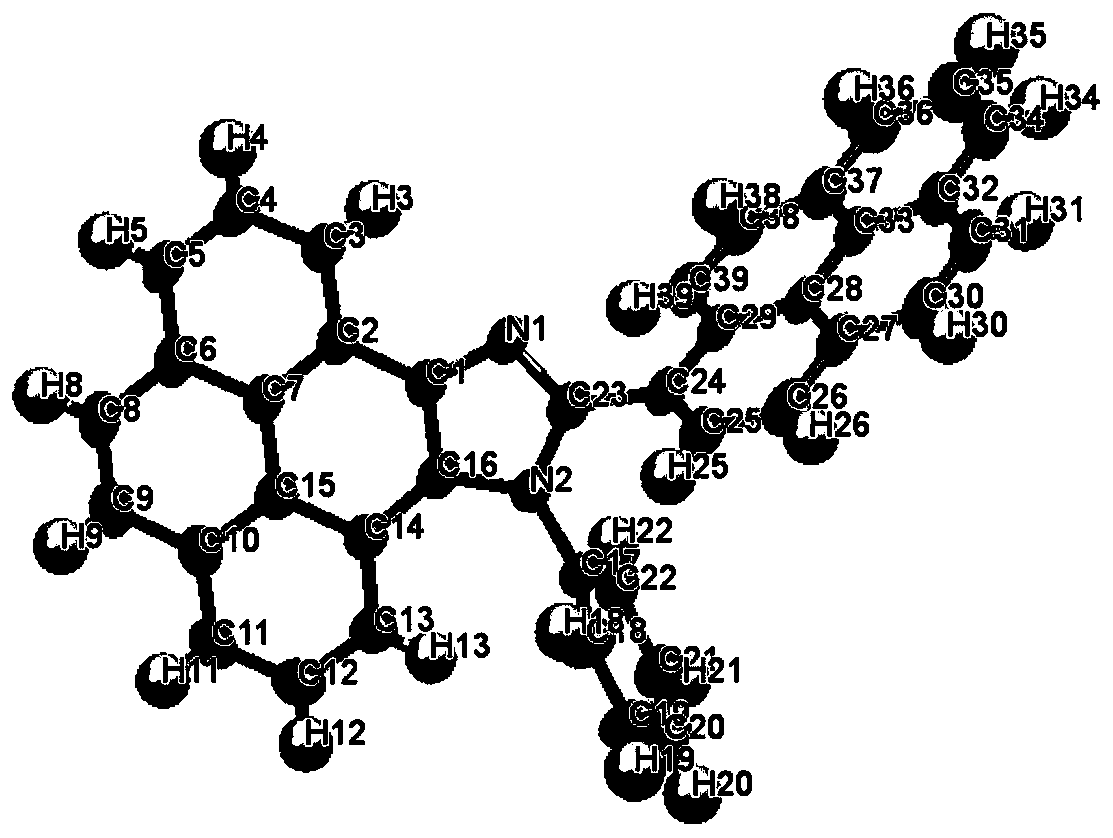

[0069] Preparation and properties of embodiment 1 luminescent material PyIPy

[0070] (1) Synthesis of 4,5-pyrene diquinone (PyDO): Dissolve elemental pyrene (2.80g, 14.0mmol) in a mixed organic solvent of 60mL dichloromethane and 60mL acetonitrile, and then NaIO 4 (12.30g, 57.3mmol), 80mL of deionized water was added to it, and finally the catalyst RuCl was added 3 ·xH 2 O (0.35g, 1.7mmol). The dark brown reaction was stirred at 20 °C for 12 hours. After the reaction was complete, the crude product was extracted with dichloromethane. The organic phase was dried with anhydrous magnesium sulfate for 6 hours and then filtered, and then the filtrate was spin-dried by a reduced-pressure rotary evaporator to obtain a dark orange solid, which was purified by column chromatography and separated by volume ratio petroleum ether:dichloromethane=1 :1 solvent as eluent. A red powder (1.21 g) was finally obtained with a yield of 36%.

[0071] 1 H NMR (500MHz, DMSO-d6, 25°C, δ): 8.34...

Embodiment 2

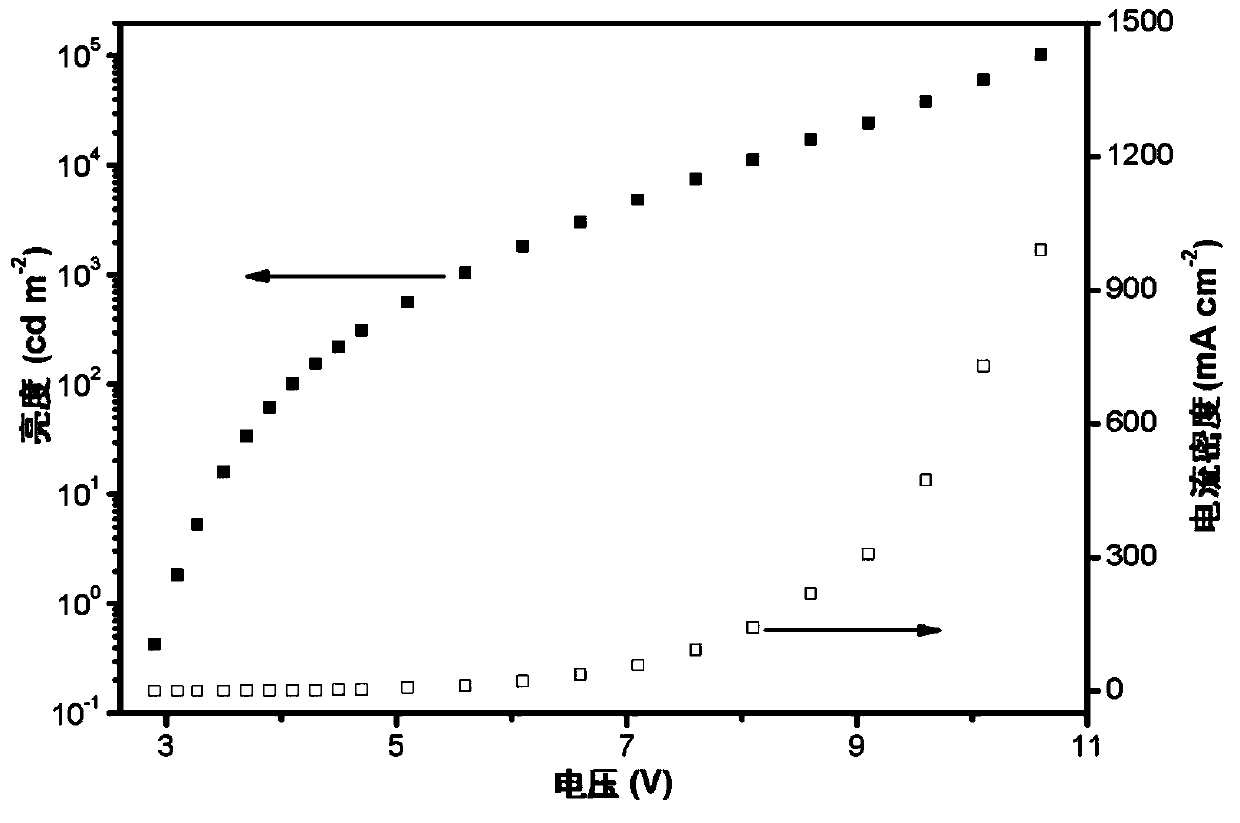

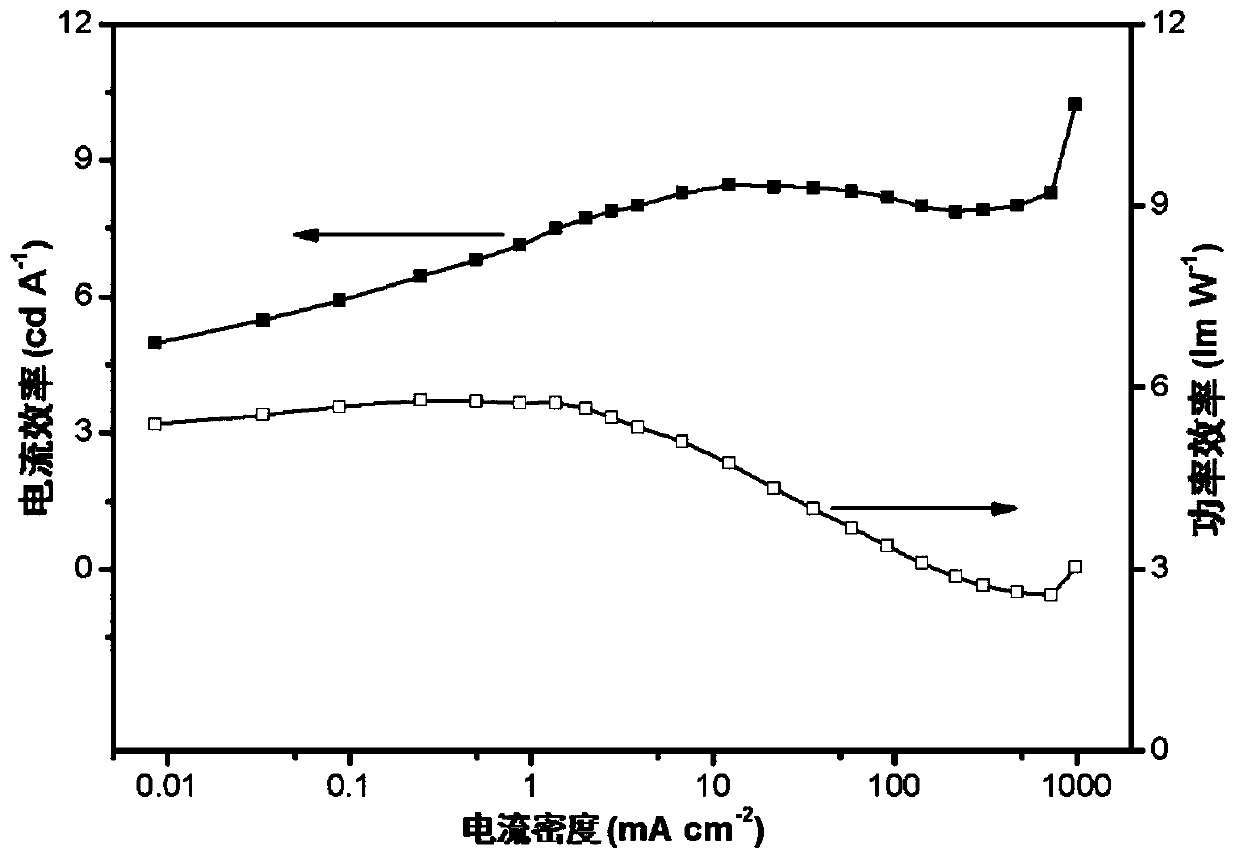

[0078] Example 2 Application of luminescent material PyIPy in organic electroluminescent devices

[0079] Device 1

[0080] This embodiment prepares blue organic electroluminescent device 1 according to the following method:

[0081]a) Preparation of substrate ITO (indium tin oxide) glass: ultrasonically clean each ITO glass with deionized water, isopropanol, acetone, toluene, acetone, trichloroethane, acetone, toluene, acetone, and isopropanol in sequence. For 30 minutes, put it in the oven to dry for later use. Before preparing the device, the surface of the ITO glass was treated for 40 minutes in an ultraviolet ozone cleaning machine, and then transferred into a vacuum evaporation equipment (pressure in the chamber-4 Pa);

[0082] b) On the anode ITO glass, the hole injection layer HATCN is vacuum evaporated, with a thickness of 6nm;

[0083] c) On the hole injection layer HATCN, a hole transport layer TAPC is vacuum evaporated with a thickness of 45nm;

[0084] d) On t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com