A device and method for measuring the diameter of a short busbar precision hole

A technology of precision holes and short busbars, applied in measuring devices, instruments, etc., can solve the problems of parts consistency, interchangeability cannot be guaranteed, parts quality cannot be effectively controlled, accurate measurement data cannot be obtained, etc. The effect of avoiding adverse effects, wide application range and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

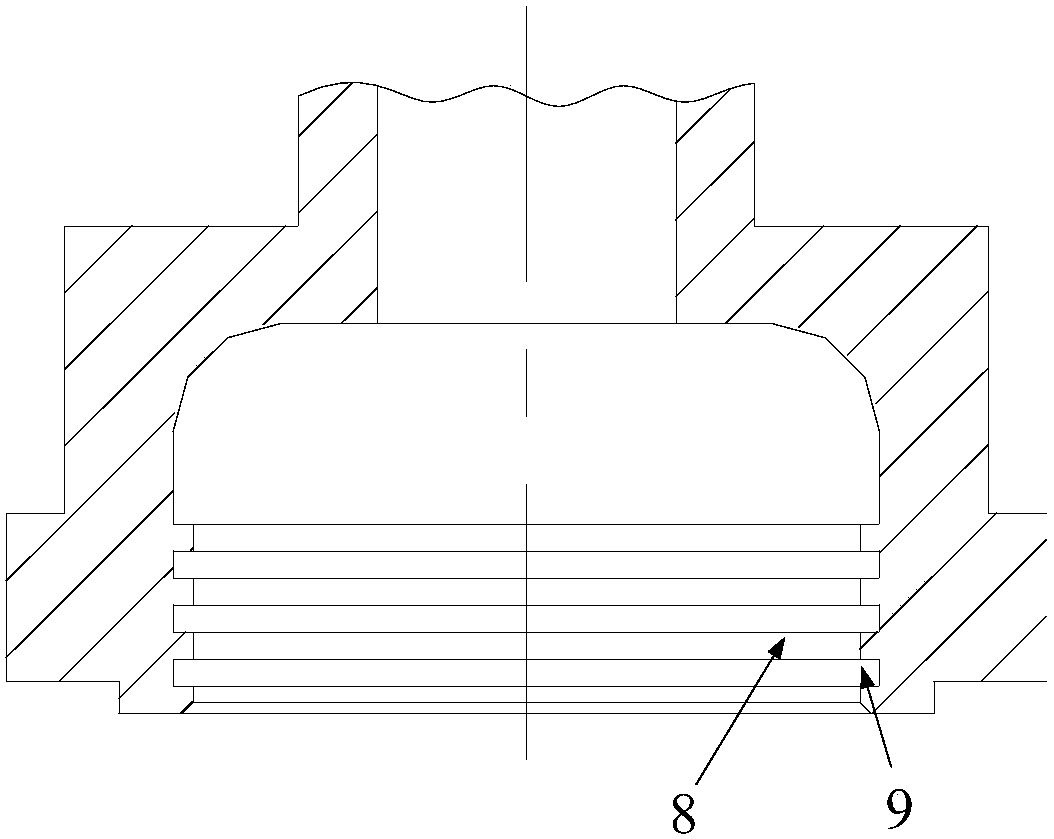

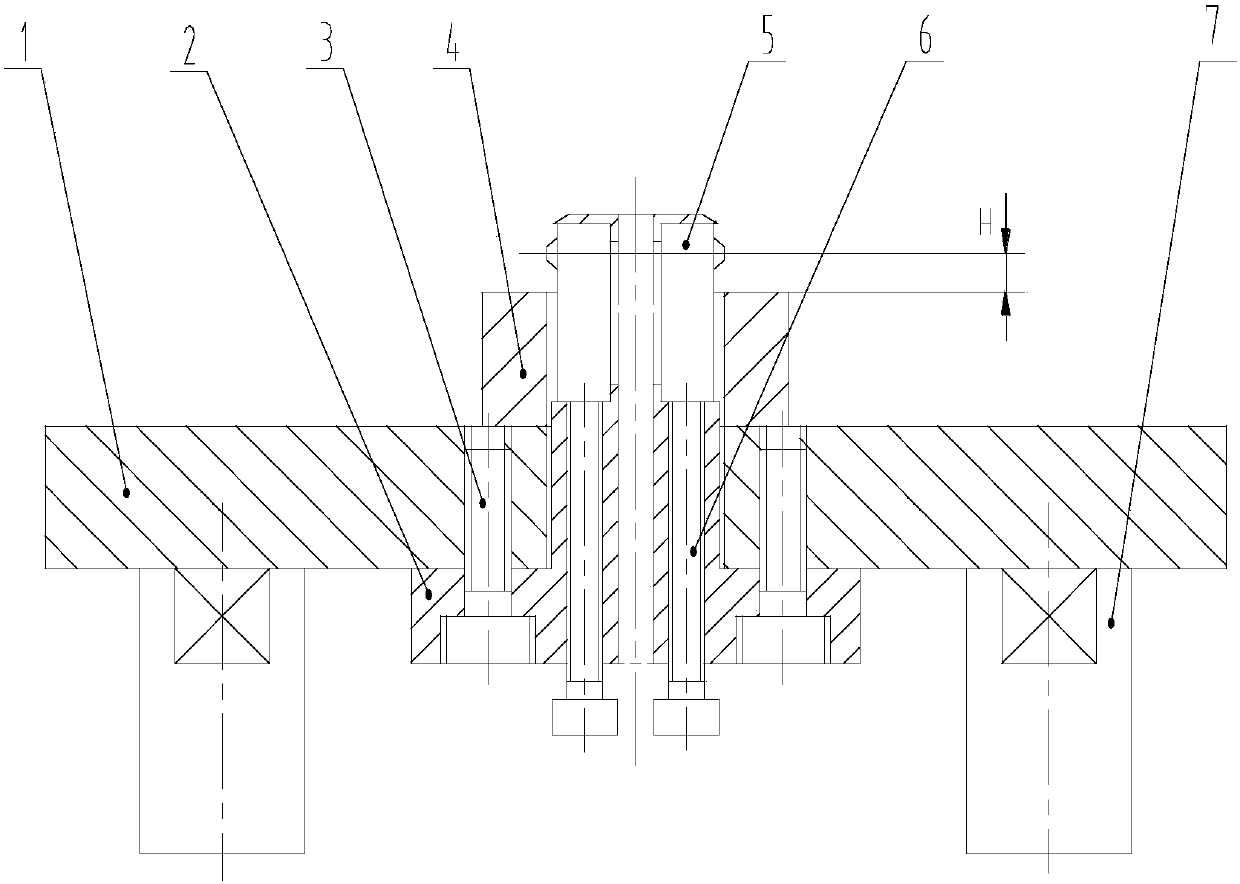

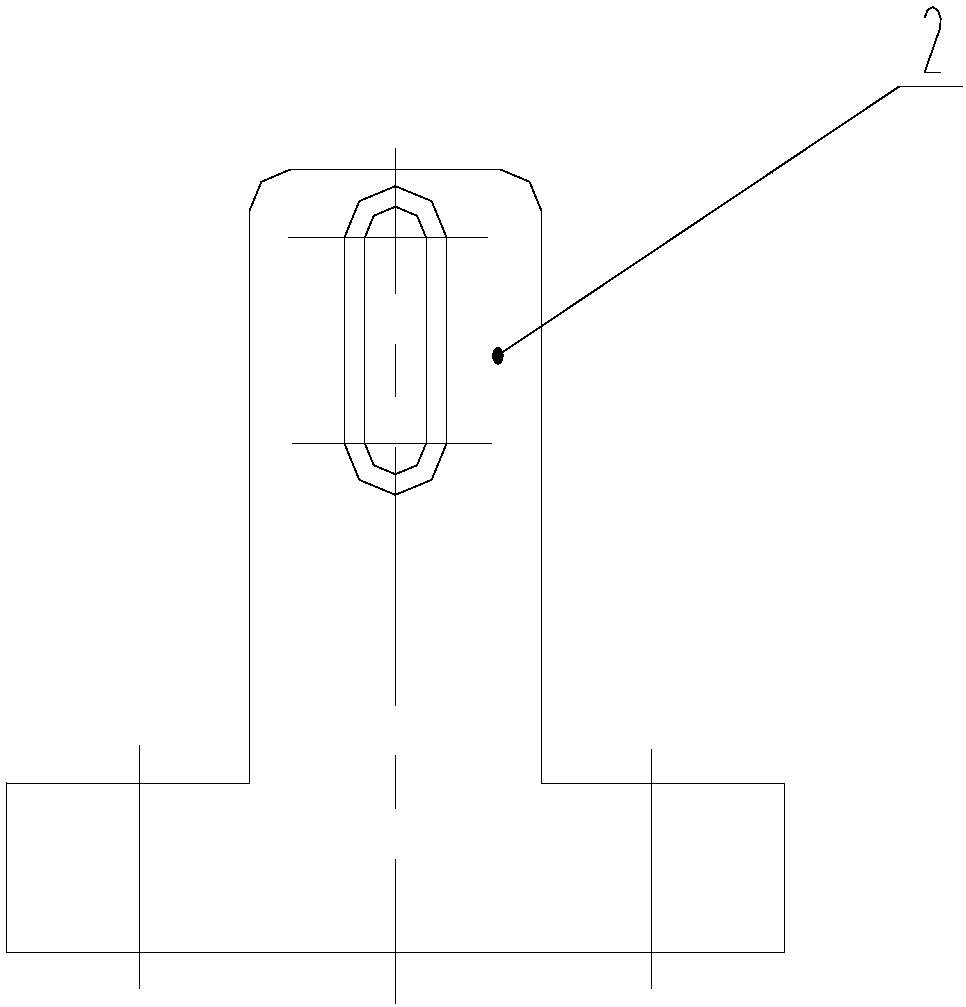

[0031] see figure 2 , the present invention includes a horizontal positioning plate 1, and a positioning mandrel 2 vertically fixed on the positioning plate 1, and two symmetrical displacement sensors 5 are installed on the side of the upper part of the positioning mandrel 2, and the displacement sensors 5 all contain contacts. The head is elastic, and can be compressed and reset to the axis of the positioning mandrel 2, that is, the inner side of the displacement sensor 5. The compression amount is 0-1mm, and is used to test the diameter of the short busbar hole 8 in the part; the diameter of the positioning mandrel 2 is less than Or equal to the diameter R1 of the short busbar hole 8, the diameter R1 of the short busbar hole 8 is less than the distance between the two contacts, the difference between the diameter of the short busbar hole 8 and the diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com