A heavy load force transmission mechanism applied to a large force bearing area

A force-bearing area and heavy-load technology, which is applied in the field of heavy-load force transmission mechanisms, can solve problems such as deviations and affect weighing accuracy, and achieve the effect of solving large deviations and improving the accuracy of force measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

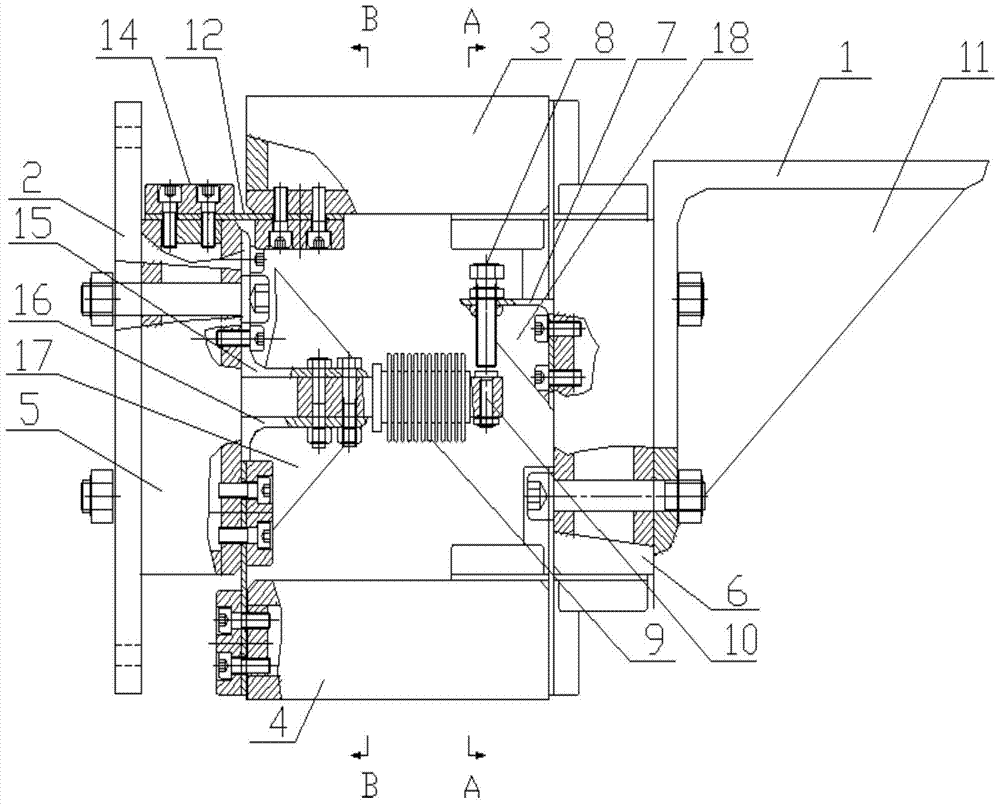

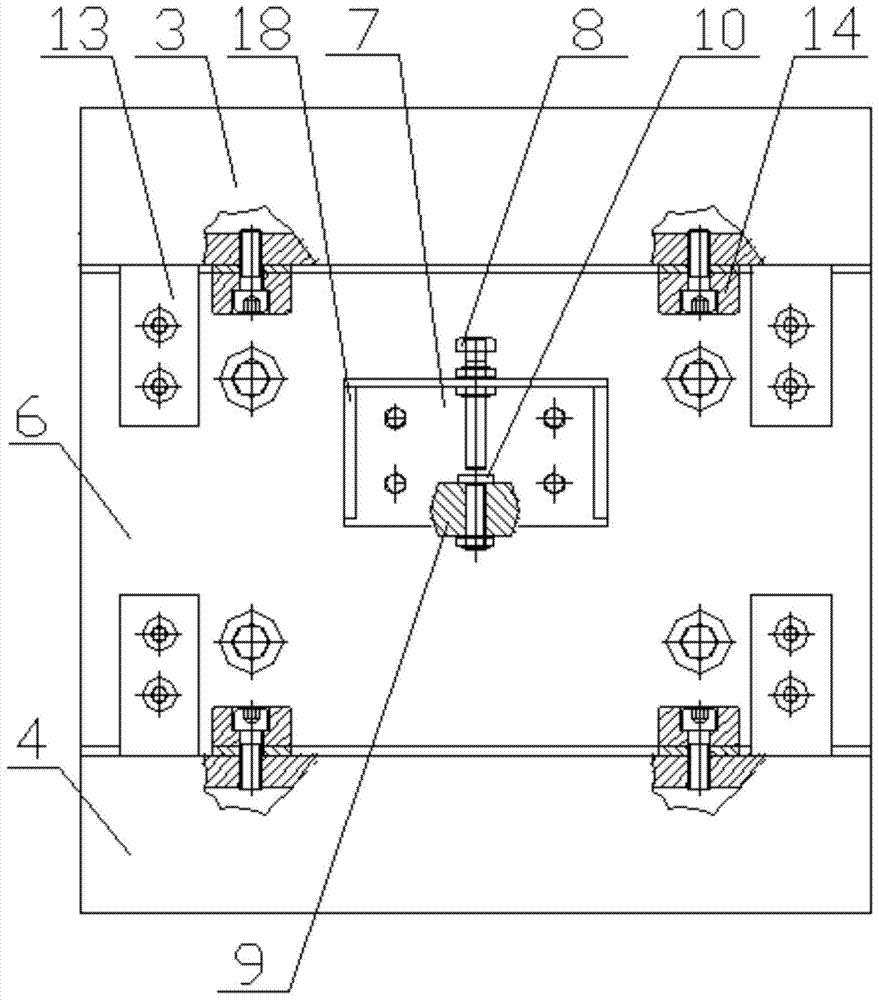

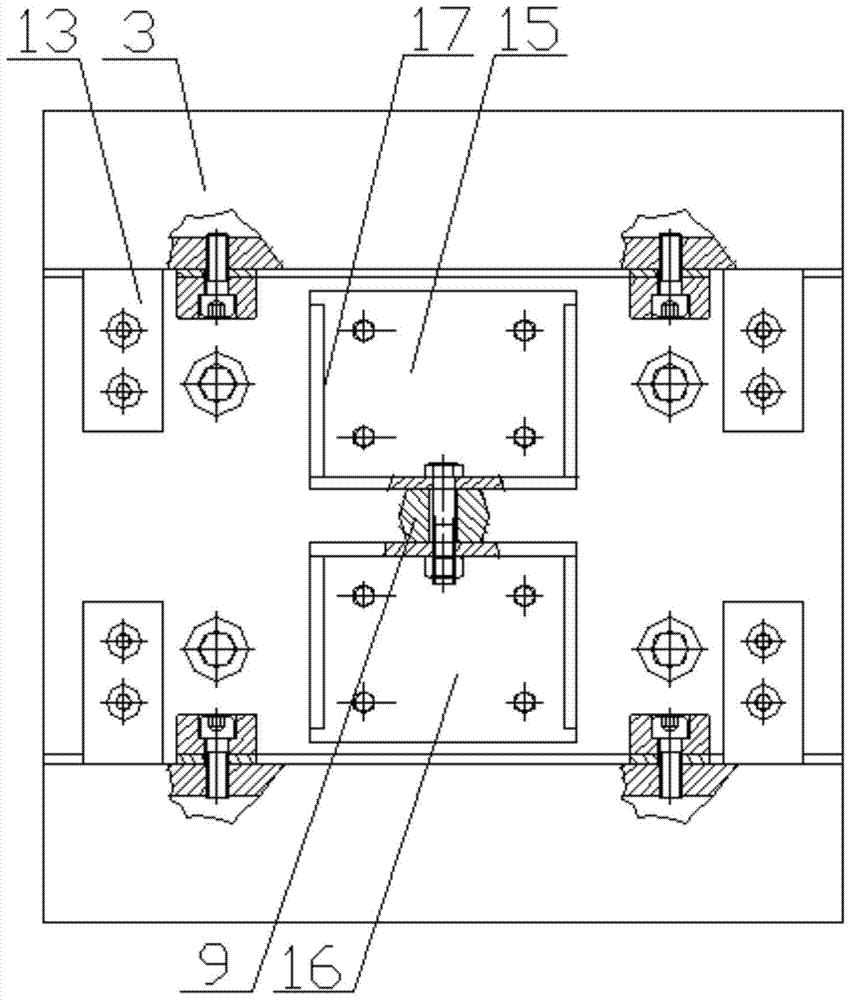

[0015] A heavy-duty force transmission mechanism applied to a large force-bearing area. The force transmission mechanism includes a load-bearing support 1, a force-transmission bracket and a fixing plate 2. The cross-section of the load-bearing support 1 is a right-angle shape, and the right-angle-shaped load-bearing support One side of the seat 1 is horizontal, and the other side is vertically downward; the force transmission support includes an upper support 3, a lower support 4, a left support 5 and a right support 6 in the shape of a hexahedron, and the upper support 3, Connecting devices are arranged between the adjacent two of the lower bracket 4, the left bracket 5, and the right bracket 6, and the vertically downward side of the load-bearing support 1 is attached to the outside of the right bracket 6 and fixed, and the inside of the right bracket 6 is attached. The ejector rod bracket 7 whose cross section is a right-angle shape is fixed together, the two sides of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com