Device for detecting sealing performance of airbag tank

An airbag and tightness technology, which is applied in the direction of measuring the acceleration and deceleration rate of the fluid, using the liquid/vacuum degree for liquid tightness measurement, etc. The problems of air tightness of studs and uncommon detection of bayonet size can achieve the effect of improving product quality, protecting products and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

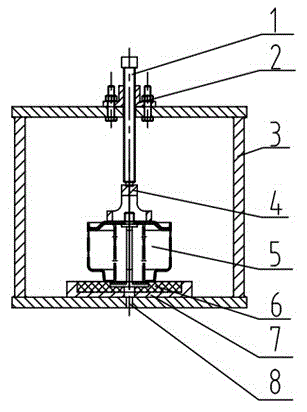

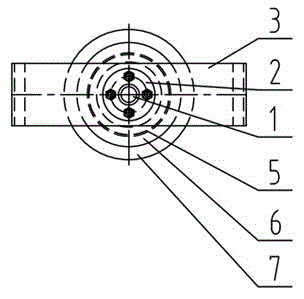

[0011] Depend on figure 1 , figure 2 Known, a kind of tightness detection device of airbag tank is made up of compression bolt 1, rotating nut 2, fixed frame 3, compression block 4, airbag tank 5, compression pad 6, inflation rod 8 of fixing seat 7, The upper and lower sides of the fixed frame 3 are provided with coaxial through holes, and the compression bolt 1 moves through the upper through hole and is fixed by the rotating nut 2. The bottom of the fixed frame 3 is provided with a fixed seat 7, and the fixed seat 7 is provided with a There is a pressing rubber pad 6, and the air bag tank 5 is arranged on the pressing rubber pad 6, and it is characterized in that: the above air bag tank 5 is provided with a pressing block 4, and the air bag tank 5 is provided with an inflation rod 8, and the air passes through The inflation rod 8 enters the inner cavity of the air bag tank 5 . The diameter of the pressing block 4 is greater than 200mm. The increase of the compression are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com