A device for detecting surface defects of bearing ball air floatation

A defect detection and rotating surface technology, used in measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to realize the full surface detection of the sphere, friction drive slippage, easy wear of the unfolding wheel, etc., to achieve safe and stable use, eliminate wear and tear, The effect of avoiding physical contact

Active Publication Date: 2019-01-22

HARBIN INST OF TECH

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a bearing ball air-floating rotating surface defect detection device to solve the problem of friction drive slippage in the detection process of the existing bearing ball detection device, easy wear of the unfolding wheel, many detection times, cumbersome steps, and stability. Low and poor controllability, the problem that the full surface of the sphere cannot be detected

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

specific Embodiment approach 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

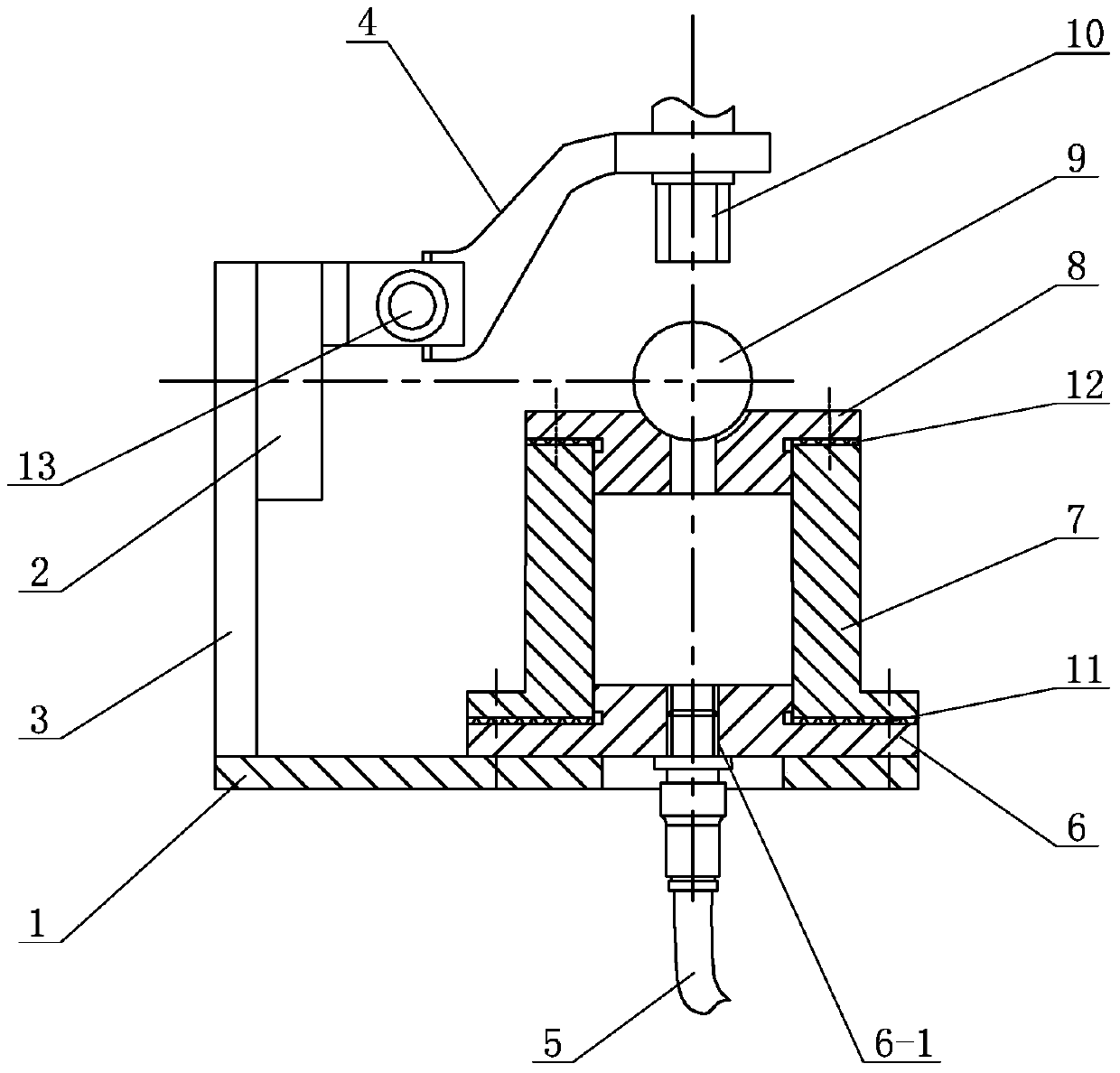

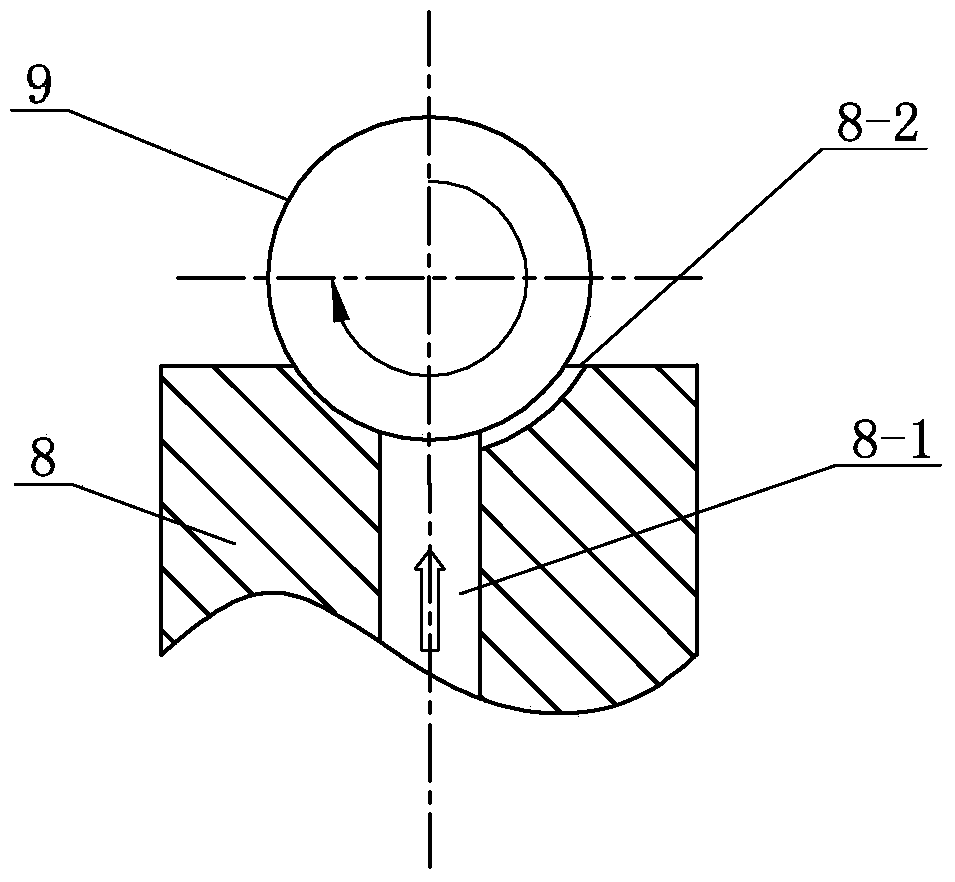

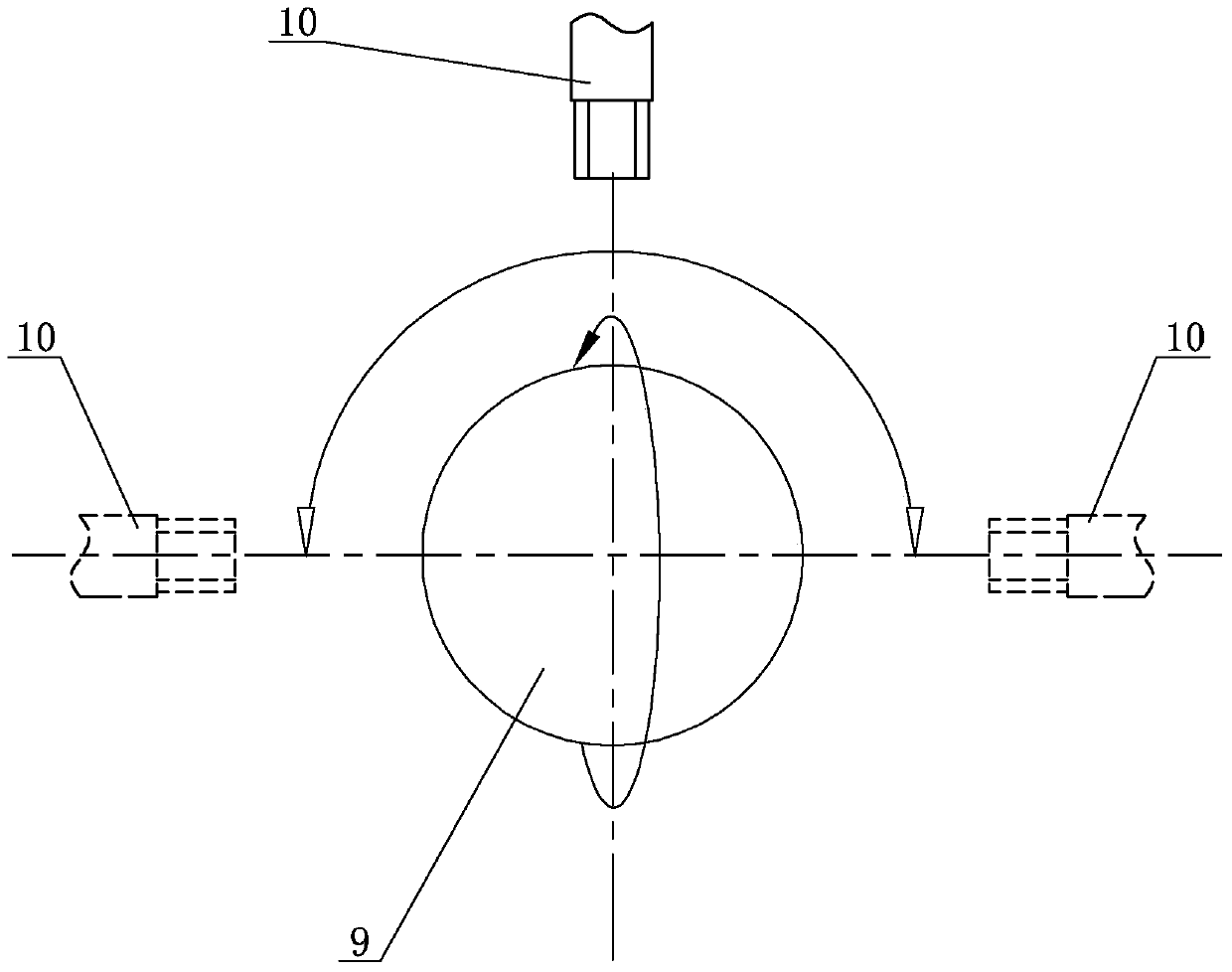

The invention discloses a bearing ball air floatation rotation surface defect detection device, and relates to a detection device. The bearing ball air floatation rotation surface defect detection device is used for solving problems of conventional bearing ball detection devices in detection processes that friction drive slipping is caused, wearing of spread wheels is easily caused, detection steps are tedious, stability is low, and controllability is poor. According to the bearing ball air floatation rotation surface defect detection device, a rotary table support is fixedly arranged on a base plate; the rotary table support is provided with a vertical rotary table; the table surface of the rotary table is fixedly connected with a microscope mechanism; a gas storage shell pedestal is horizontally arranged on the base plate and below the microscope mechanism; a gas storage shell is arranged on the gas storage shell pedestal; the top end of the gas storage shell is provided with an upper cover; the gas storage shell pedestal is provided with an air inlet passage; the upper cover is provided with an air nozzle; the side wall of the air nozzle is provided with an air outlet groove; a bearing ball is placed on the air nozzle; a gas storage chamber is arranged in the gas storage shell; the upper end and the lower end of the gas storage chamber are communicated with the air nozzle and the air inlet passage respectively; and a pneumatic rotating joint is arranged in the air inlet passage and is communicated with the air inlet passage. The bearing ball air floatation rotation surface defect detection device is used for detecting bearing ball surface defects.

Description

technical field The invention relates to a device for detecting defects on the air-floating rotating surface of a bearing ball. Background technique Rolling bearings are essential and key basic parts of mechanical systems, which have an important impact on their running accuracy, ultimate performance, reliability and other aspects. Ball bearings are the most common type of rolling bearings and are used in a wide variety of mechanical systems. The running accuracy, service life and limit index of the ball bearing largely depend on its core - the bearing ball. The surface defects of bearing balls will not only reduce the wear resistance and lead to a significant reduction in strength, but also often cause local stress concentration and become the origin of fracture, which can easily lead to damage to parts and seriously affect the running accuracy, fatigue life and reliability. According to statistics, 60% of bearing failures are due to cracks and cracks caused by surface d...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N21/952

Inventor 赵小力安伟伟张传伟郑德志古乐王黎钦

Owner HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com