Stick-slip driving cross-scale precision positioning platform provided with side part friction force adjusting mechanism

An adjustment mechanism and precise positioning technology, which can be applied to generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., and can solve the problems of complex friction and limited adjustment of friction. To achieve the effect of large preload adjustment range, avoid friction changes, and ensure movement accuracy and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] As mentioned in the background technology, in the existing stick-slip drive cross-scale precision positioning platform, the friction force is adjusted up and down, and the friction force adjustment method is affected by the load change. At the same time, the friction preload structure and adjustment method are relatively complicated. The friction adjustment is limited and the accuracy is affected.

[0036] Next, the specific technical solution of the present invention will be introduced in detail.

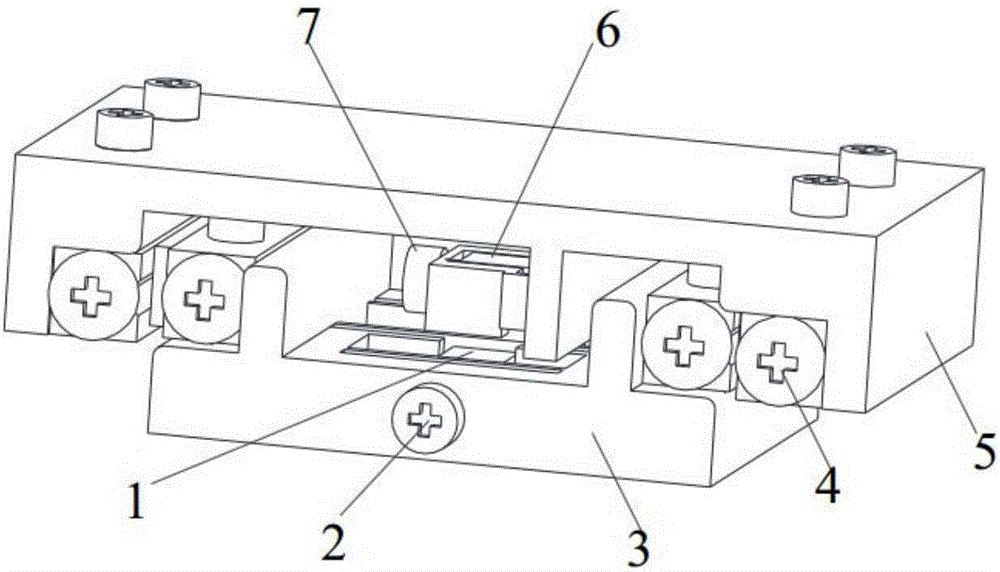

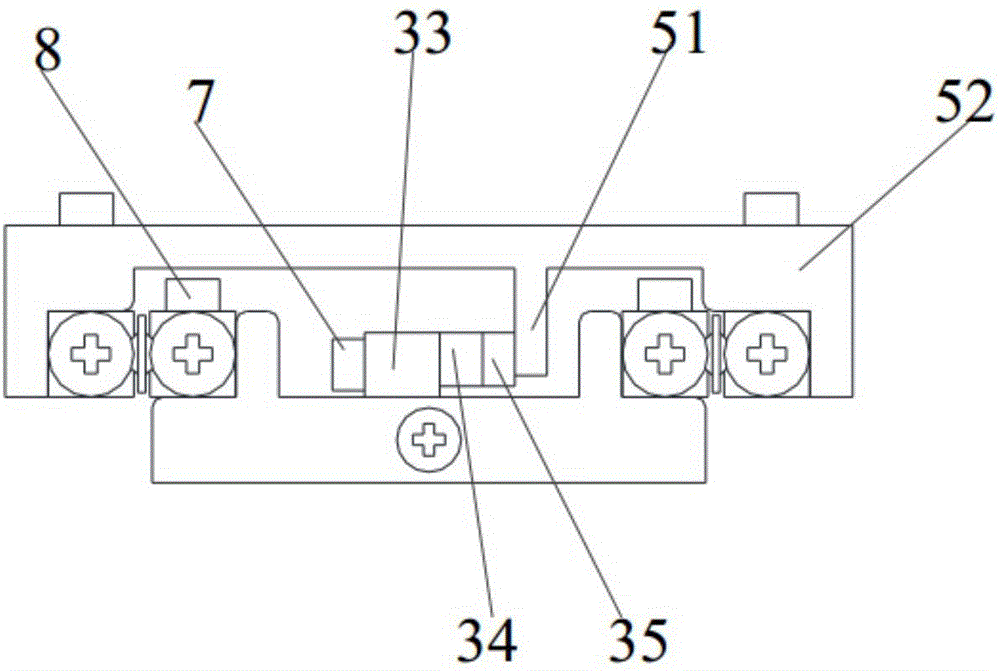

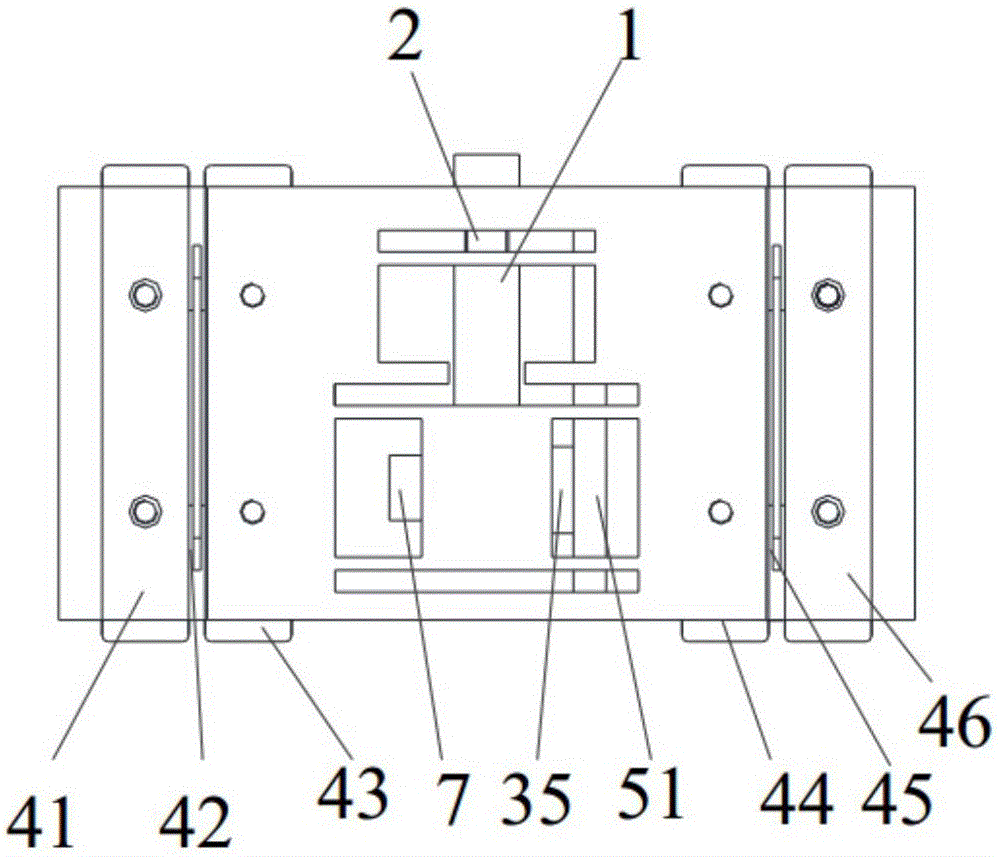

[0037] Please also see Figure 1 ~ Figure 4 , the stick-slip driving cross-scale precision positioning platform in the present invention includes:

[0038] Abutment 3, the abutment 3 includes a base, a pre-tightening flexible hinge 37, a drive transmission flexible hinge 32, an inertia mass block 36, and has a pre-tightening screw 2, and a piezoelectric ceramic 1, and the piezoelectric ceramic 1 is installed on the base and Between the inertial mass blocks 36, one end is p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap