Upper part pretightening stick-slip driving multi-scale precision motion platform

A precision motion and cross-scale technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problem of small friction preload adjustment range, high cost, Problems such as tight structure and complex adjustment methods are achieved to ensure motion accuracy and consistency, ensure motion performance and consistency, and simplify preload adjustment methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention discloses an upper pre-tightened stick-slip drive cross-scale precision motion platform, which greatly simplifies the pre-tightening mechanism and adjustment mode, facilitates processing and assembly, and further effectively improves the output of the stick-slip drive cross-scale positioning platform Performance, thereby improving the motion accuracy and consistency of the stick-slip drive cross-scale positioning platform, suitable for industrialization and mass production.

[0029] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

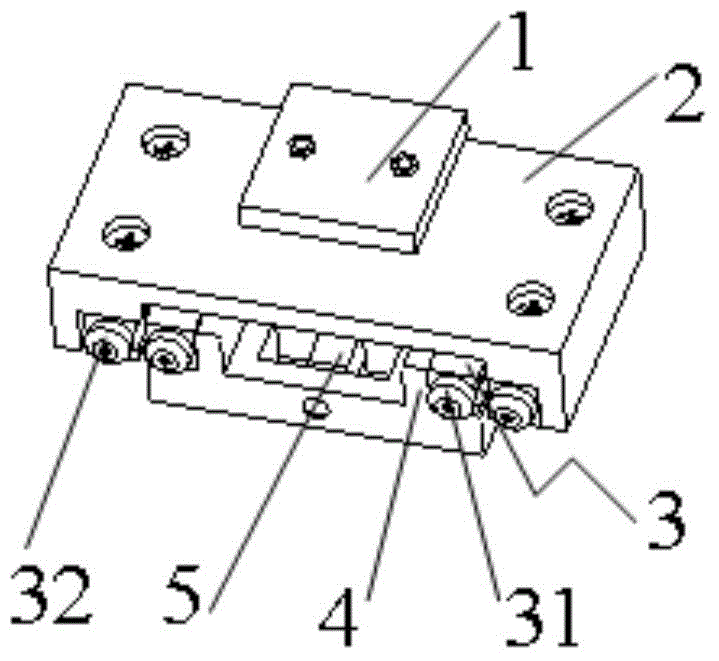

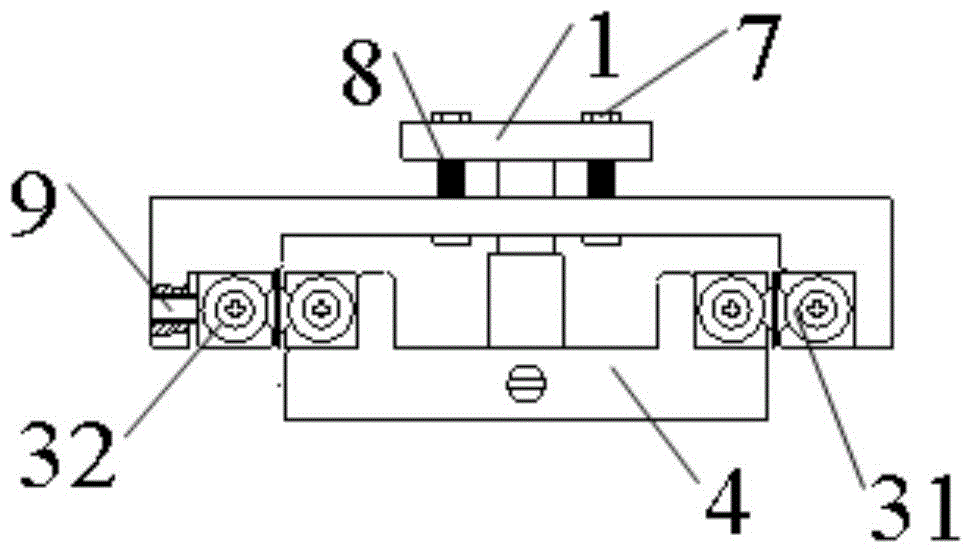

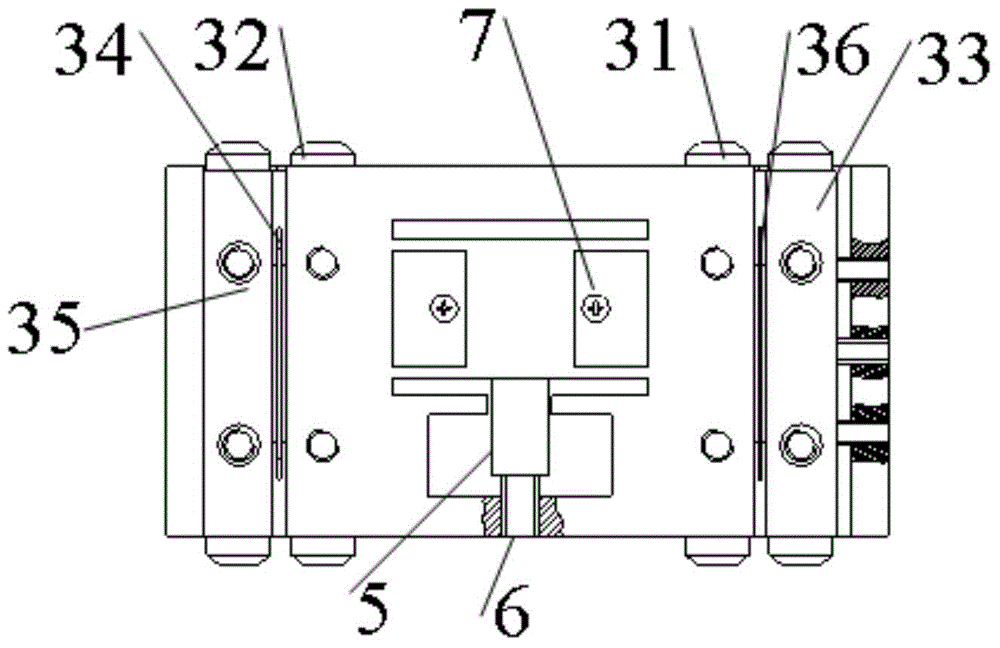

[0030] An upper pre-tightened stick-slip driven cross-scale precision motion platform is characterized in that it includes a base 4, a sliding device, a guide rail 3, a friction vibrator 42 and a vibrator drive source.

[0031] Among them, such as Figure 1 ~ Figure 3 As shown, the guide rail 3 is installed o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap