Adjustable pre-tightening stick-slip driving positioning platform based on flexible hinge

A technology of flexible hinges and positioning platforms, which is applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problem of affecting the movement accuracy and consistency of cross-scale precision sliding tables, and the high processing and assembly accuracy requirements of stick-slip drive platforms. It is difficult to adapt to problems such as small differences in the friction interface, to achieve the effect of improving the stick-slip effect, simplifying the preload adjustment method, and having no mechanical friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] As mentioned in the background technology, the existing stick-slip drive positioning platform, the friction pre-tightening structure and adjustment method are too complicated, which will limit the friction adjustment, and these solutions are all for the processing of the friction interface. Higher precision requirements lead to higher machining and assembly precision requirements for the stick-slip drive platform, which ultimately affects the motion precision and consistency of the cross-scale precision slide table.

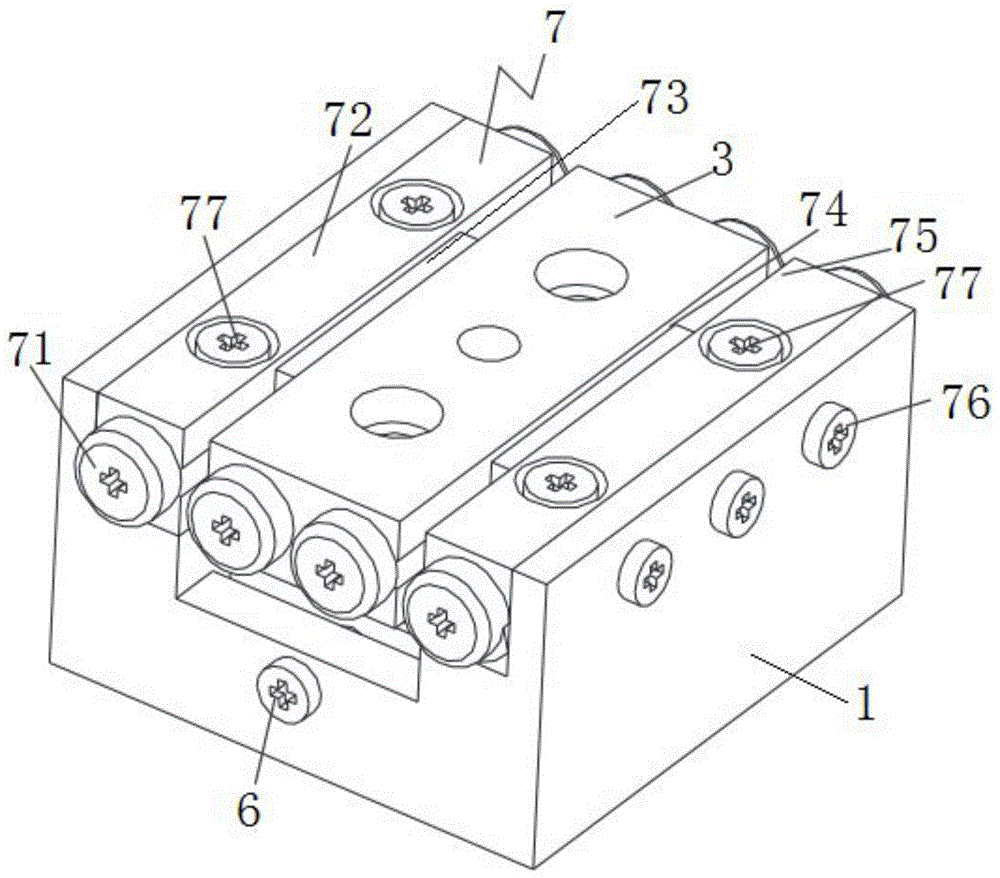

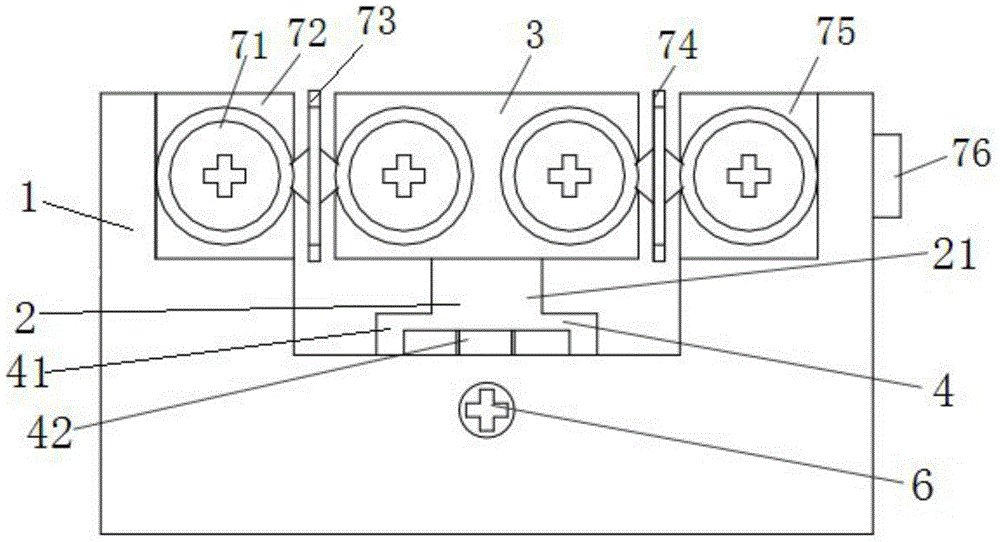

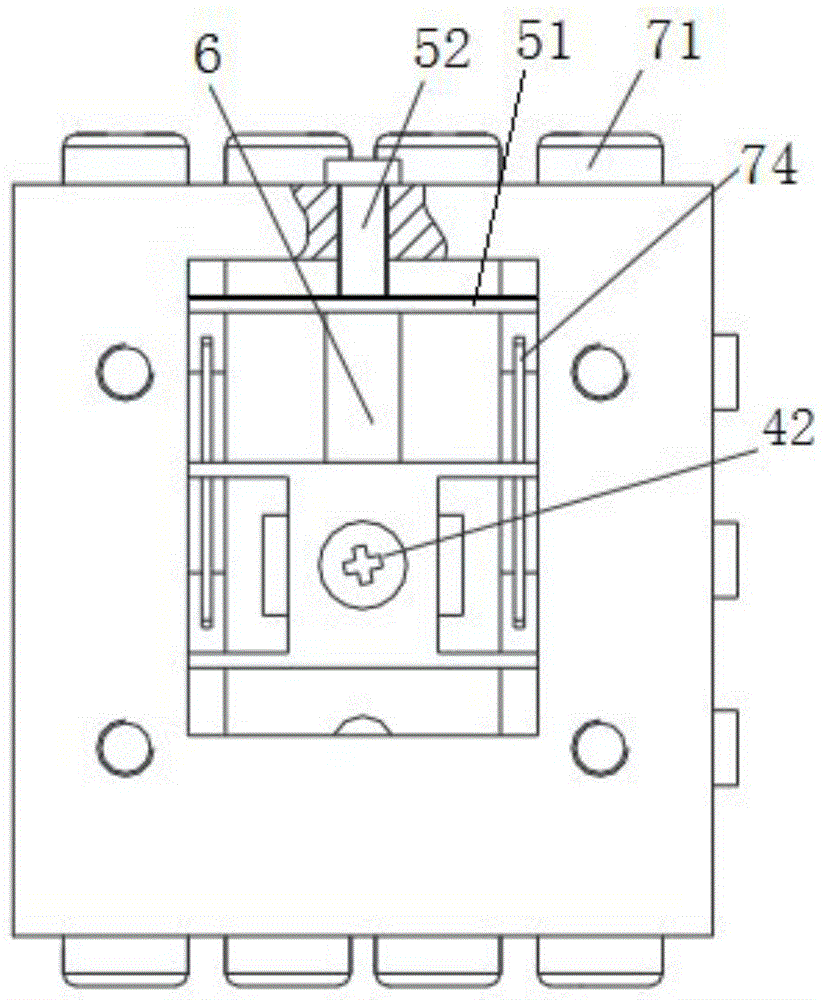

[0027] The invention discloses an adjustable pre-tightened stick-slip driving positioning platform, which comprises a base, a friction vibrator installed on the base, a vibrator driving source installed between the base and the friction vibrator, and a vibrator arranged above the friction vibrator. Slider;

[0028] The friction vibrator includes a transmission flexible hinge, an inertial mass block and a boss, the upper part of the boss is in direct contac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap