Syngas to olefins catalyst and method of use thereof

A catalyst and synthesis gas technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as poor C2-C4 olefin selectivity, improve selectivity, improve activity, and avoid secondary reactions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

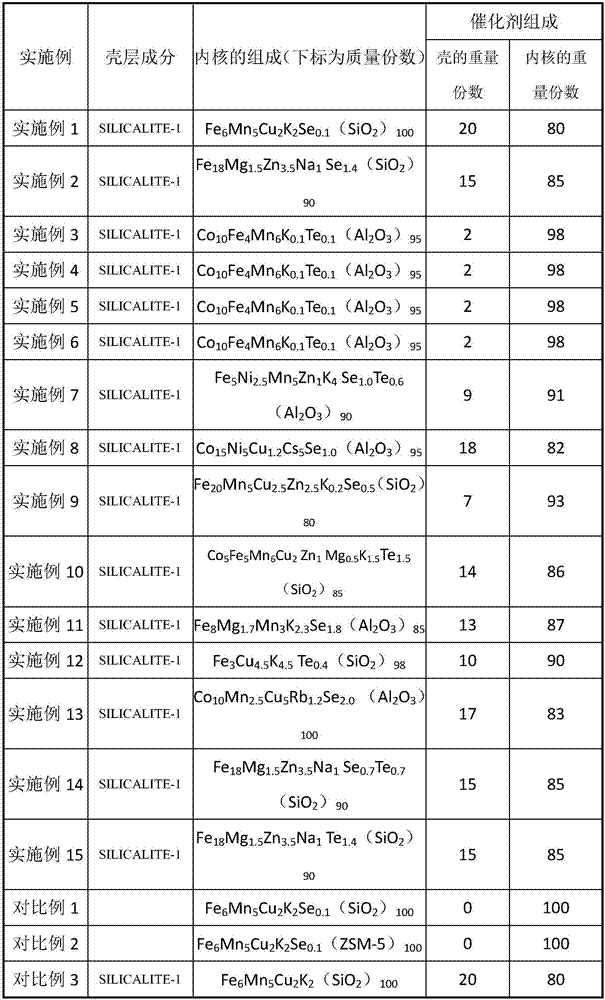

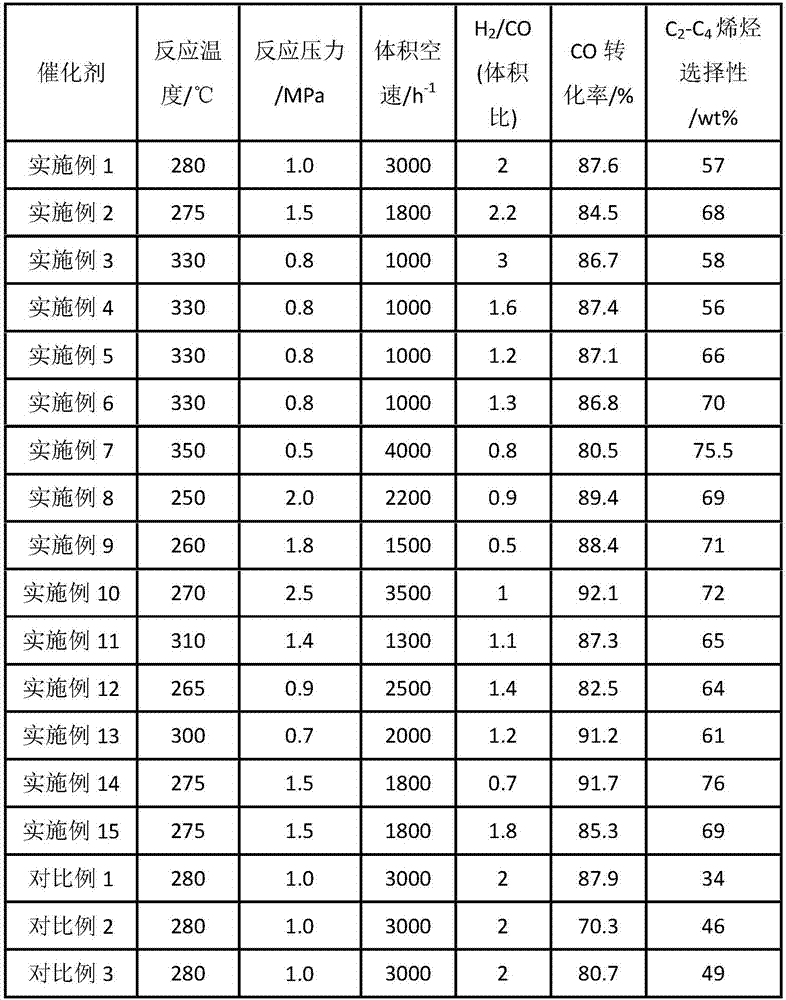

Examples

Embodiment 1

[0027] 24.9g of ferric nitrate hexahydrate, 21.6g of manganese nitrate with a mass concentration of 50% and 5.04g of copper nitrate trihydrate were dissolved in water to form a solution.

[0028] Weigh 66.3g of silica carrier, impregnate the above solution on the carrier, and bake at 60°C until there is no excess moisture outside the catalyst particles.

[0029] Add 0.15 g of ammonium selenate to 9.5 g of potassium hydroxide solution with a mass concentration of 20%, then add it into the catalyst and stir evenly, let it stand for 10 minutes, then bake at 100°C for 4 hours, and then roast at 600°C for 2 hours to obtain the catalyst core .

[0030] Using PDDA (polydiallyldimethylammonium chloride) as a binder, the nano-crystal seed of SILICALITE-1 molecular sieve is adsorbed on the catalyst core, and added to the molecular sieve synthesis liquid for reaction, forming a layer of SILICALITE outside the catalyst core -1 molecular sieve molecular sieve shell, dried at 100°C for 4 hou...

Embodiment 2

[0032] Dissolve 76.2g of ferric nitrate hexahydrate, 10.8g of zinc nitrate hexahydrate and 10.7g of magnesium nitrate hexahydrate in water to form a solution.

[0033] Weigh 60.7g of the silica carrier, impregnate the above solution on the carrier, and bake at 60°C until there is no excess moisture outside the catalyst particles.

[0034] Add 2.14 grams of ammonium selenate to 5.84 grams of sodium hydroxide solution with a mass concentration of 20%, then add it to the catalyst and stir evenly, let it stand for 10 minutes, then bake at 80°C for 8 hours, and then roast at 700°C for 8 hours to obtain the catalyst core .

[0035] Using PSS (sulfonated polystyrene) as a binder, the SILICALITE-1 molecular sieve nano-crystal seeds are adsorbed on the catalyst core, added to the molecular sieve synthesis liquid for reaction, and a layer of SILICALITE-1 molecular sieve molecular sieve shell is formed outside the catalyst core. Dry at 80°C for 8 hours and calcined at 600°C for 2 hours ...

Embodiment 3

[0037] 19.9g of ferric nitrate hexahydrate, 31g of manganese nitrate with a mass concentration of 50% and 47.5g of cobalt nitrate hexahydrate were dissolved in water to form a solution.

[0038] Weigh 75.1g of alumina carrier, impregnate the above solution on the carrier, and bake at 60°C until there is no excess moisture outside the catalyst particles.

[0039] Add 0.15 g of ammonium tellurate to 0.57 g of potassium hydroxide solution with a mass concentration of 20%, then add it to the catalyst and stir evenly, let it stand for 10 minutes, then bake at 120°C for 7.5 hours, and then bake at 650°C for 6 hours to obtain the catalyst core .

[0040] Using APTS (8-aminopyrene-1,3,6-triammonium trisulfonate) as a binder, the SILICALITE-1 molecular sieve nano-crystal seeds were adsorbed on the catalyst core, and added to the molecular sieve synthesis solution to react. A layer of SILICALITE-1 molecular sieve molecular sieve shell was formed outside the inner core, dried at 120°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com