Catalyst for olefin prepared by synthesis gas and preparation method of catalyst

A technology for synthesis gas and catalyst, which is applied in molecular sieve catalysts, chemical instruments and methods, preparation of liquid hydrocarbon mixtures, etc., to achieve good technical effects, improve activity, and improve selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

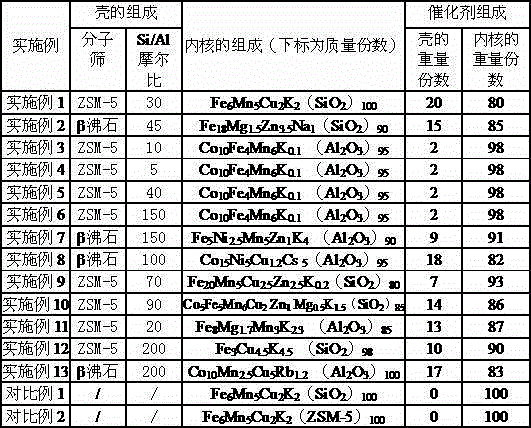

Examples

Embodiment 1

[0023] Dissolve 24.9g of ferric nitrate hexahydrate, 21.6g of manganese nitrate with a mass concentration of 50% and 5.04g of copper nitrate trihydrate in water to form a solution.

[0024] Weigh 66.3g of silica carrier, impregnate the above solution on the carrier, and bake at 60°C until there is no excess moisture outside the catalyst particles.

[0025] Add 9.51 g of potassium hydroxide solution with a mass concentration of 20%, stir evenly, let stand for 10 minutes, then bake at 100°C for 4 hours, and then roast at 600°C for 2 hours to prepare the catalyst core.

[0026] The slurry containing 20 grams of ZSM-5 molecular sieves with a Si / Al molar ratio of 30 was sprayed onto the prepared catalyst core, dried at 100°C for 4 hours, and calcined at 550°C for 2 hours to obtain the catalyst 80Fe 6 mn 5 Cu 2 K 2 (SiO 2 ) 100-20 (ZSM-5), the numbers outside the brackets are parts by weight.

[0027]

Embodiment 2

[0029] Dissolve 77.4g of ferric nitrate hexahydrate, 10.9g of zinc nitrate hexahydrate and 10.86g of magnesium nitrate hexahydrate in water to form a solution.

[0030] Weigh 61.7g of silica carrier, impregnate the above solution on the carrier, and bake at 60°C until there is no excess moisture outside the catalyst particles.

[0031] Add 14 g of sodium hydroxide solution with a mass concentration of 20%, stir evenly, let stand for 10 minutes, then bake at 80°C for 8 hours, and then roast at 700°C for 8 hours to prepare the catalyst core.

[0032] Spray-coat the slurry containing 15 grams of β molecular sieve with a Si / Al molar ratio of 45 on the prepared catalyst core, dry at 80°C for 8 hours, and roast at 600°C for 2 hours to obtain the catalyst 85Fe 18 Mg 1.5 Zn 3.5 Na 1 (SiO 2 ) 90 -15β, the numbers outside the brackets are parts by weight.

[0033]

Embodiment 3

[0035] Dissolve 19.9g of ferric nitrate hexahydrate, 31.01g of manganese nitrate with a mass concentration of 50% and 47.5g of cobalt nitrate hexahydrate in water to form a solution.

[0036] Weigh 75.4g of alumina carrier, impregnate the above solution on the carrier, and bake at 60°C until there is no excess moisture outside the catalyst particles.

[0037] Add 0.55 g of potassium hydroxide solution with a mass concentration of 20%, stir evenly, let stand for 10 minutes, then bake at 120°C for 7.5 hours, and then roast at 650°C for 6 hours to obtain the catalyst core.

[0038] A slurry containing 2 grams of ZSM-5 molecular sieve with a Si / Al molar ratio of 10 was sprayed onto the prepared catalyst core, dried at 120°C for 7.5 hours, and calcined at 400°C for 7.5 hours to obtain the catalyst 98 Co 10 Fe 4 mn 6 K 0.1 (Al 2 o 3 ) 95 -2 (ZSM-5), the numbers outside the brackets are parts by weight.

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com