Novel intelligent universal high-speed screwing assembly robot

A robot and intelligent technology, applied in the field of robots, can solve the problems of high cost, complex locking mechanism, and the locking height cannot be changed at will, and achieves the effect of uniform power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

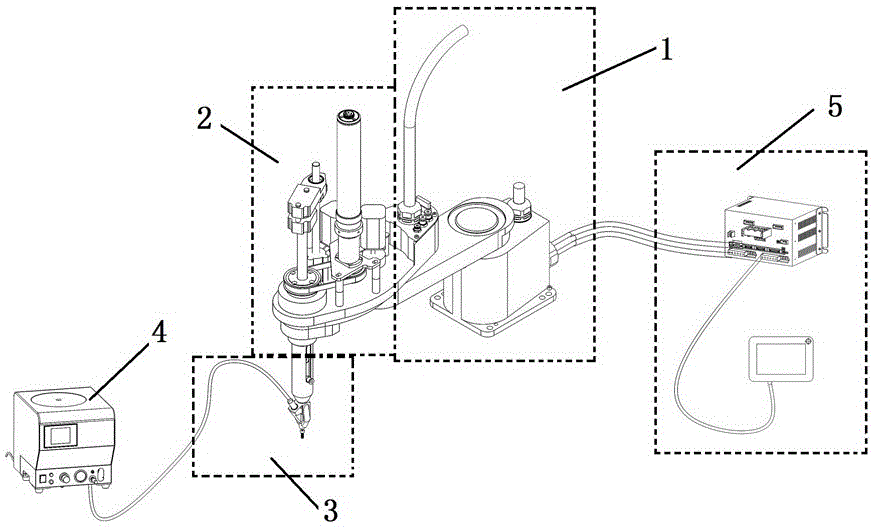

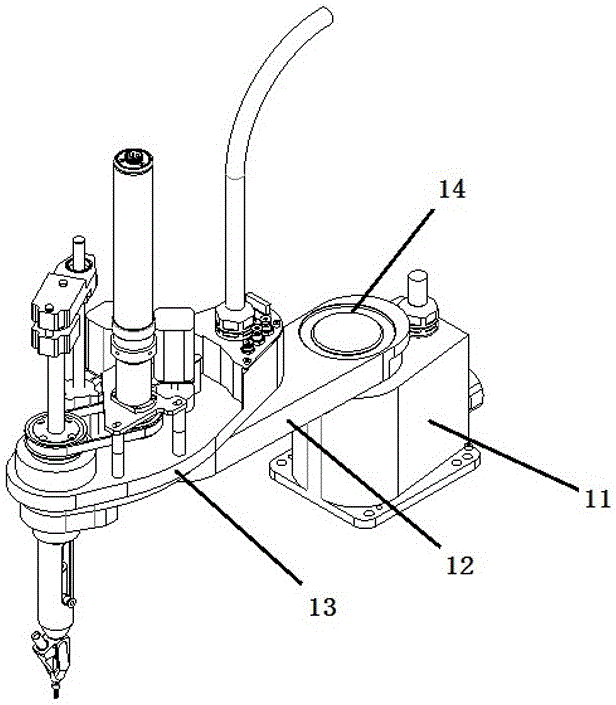

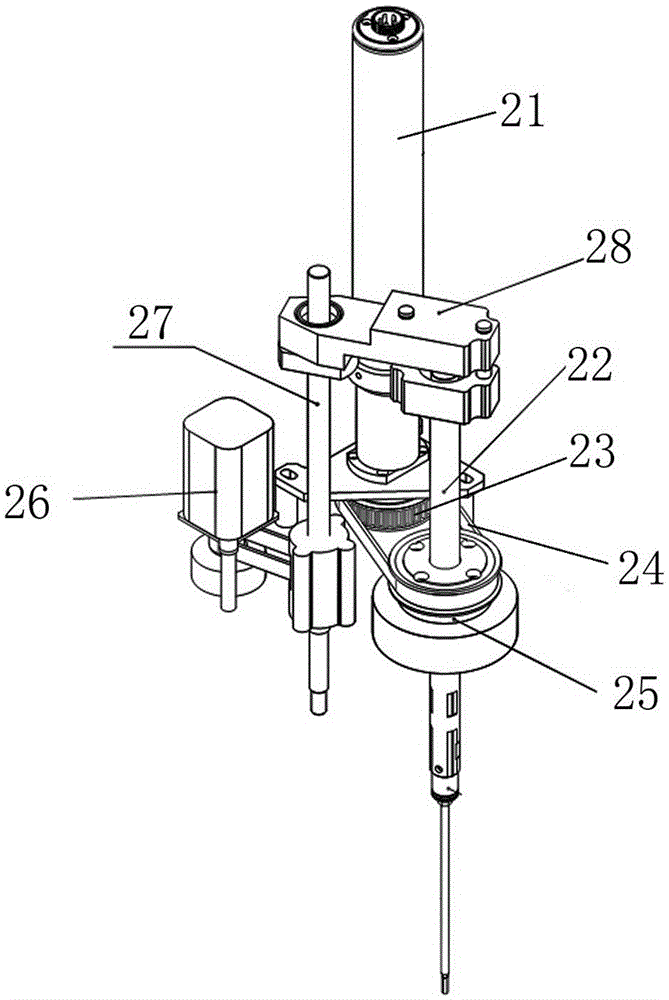

[0048] A new intelligent general-purpose high-speed screwing and assembly robot is composed of the following five parts: a horizontal joint robot base 1, a locking device 2, a top loading device 3, a screw feeder 4, and a robot controller 5; the above five parts The relationship is as follows: the base 1 of the horizontal joint robot is used as the base for bearing and supporting, and is responsible for the displacement in the horizontal direction; while the locking device 2 is installed on the base 1 of the horizontal joint robot, which is responsible for the locking action of screws and rivets, and is also responsible for the vertical displacement. Displacement positioning in the direction; the top loading device 3 is installed under the locking device 2; the locking device 2 provides power for the top loading device 3 to rotate and go down, and the top loading device 3 adsorbs the screws or rivets on the batch for locking , to facilitate the positioning of rivets or screws; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com