Fixing device of stand column hinge reinforcer mold machine

A technology for fixing devices and reinforcements, applied in positioning devices, metal processing machinery parts, clamping, etc., can solve the problem that the fixing device cannot be used for blanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

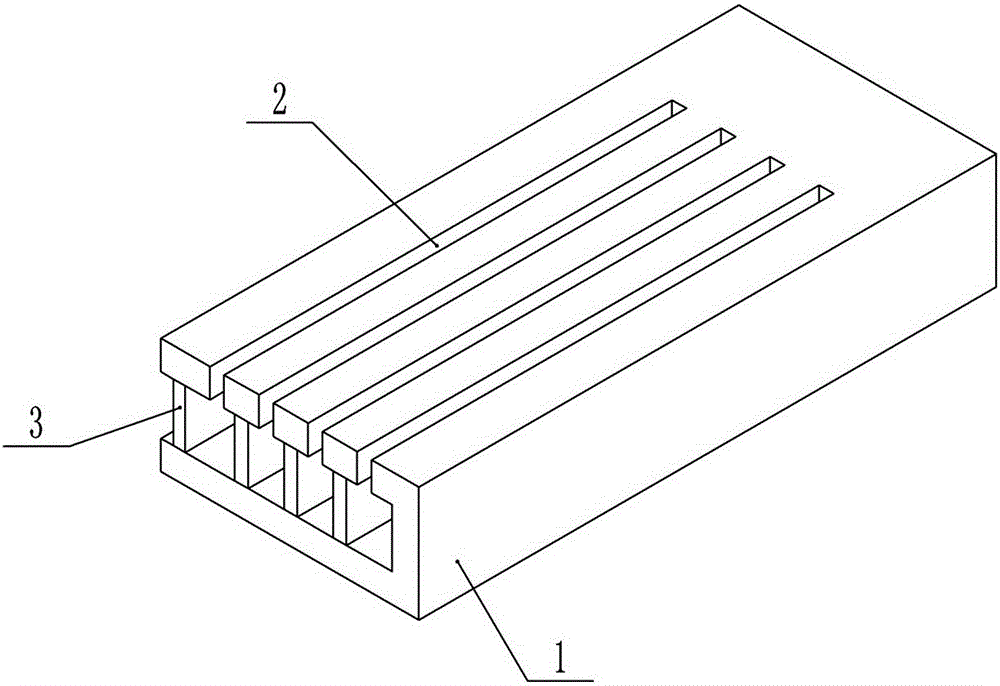

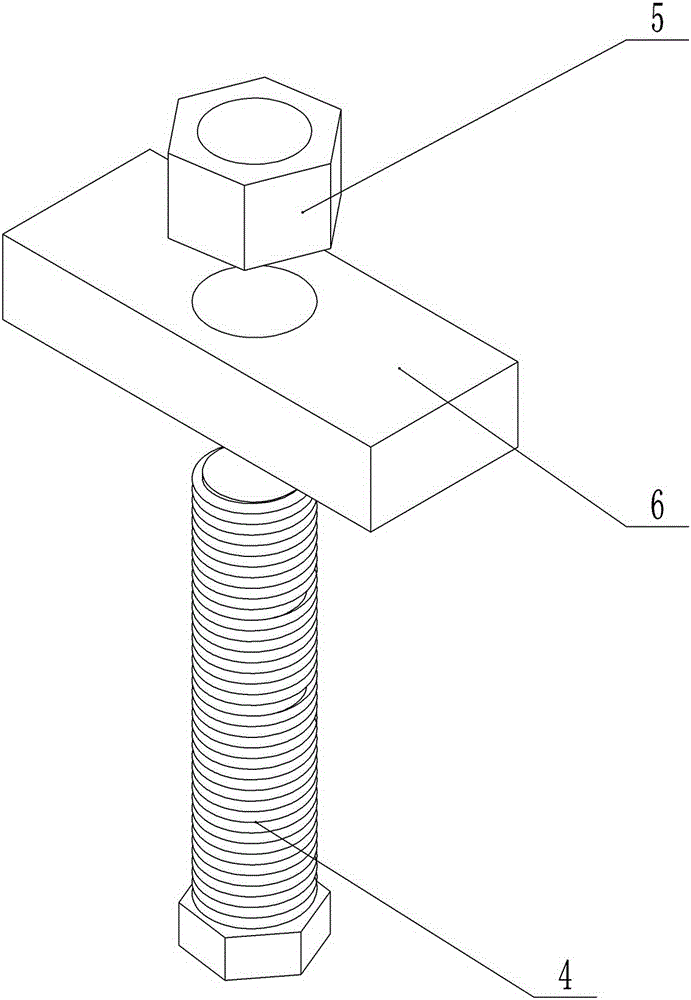

[0015] The reference signs in the accompanying drawings of the specification include: base 1 , strip groove 2 , support block 3 , bolt 4 , nut 5 , and pressing block 6 .

[0016] Such as figure 1 , figure 2 As shown, a mold machine fixing device for a column hinge reinforcement includes a base 1 , a support block 3 , bolts 4 , nuts 5 matching the bolts 4 , and a compression block 6 . Wherein, the base is a sideways U-shape, and the upper surface of the base is provided with a strip groove 2, and the number of the strip groove 2 is four, and the width of the strip groove 2 is 1.5cm, and the diameter of the stud in the bolt 4 is 1.2cm, and the diameter of the bolt head is 2cm. Support blocks 3 are welded between the upper and lower side walls of the base, and the distance between every two support blocks 3 is 4 cm, which is greater than the outer diameter of the bolt he...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap