General equipment for automatically pasting protective film on mobile phone frame and its film pasting method

A mobile phone frame and protective film technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of high labor intensity of employees, broken screens, and unsatisfactory sticker effects, and reduce manual intervention. , ensure accuracy, improve quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

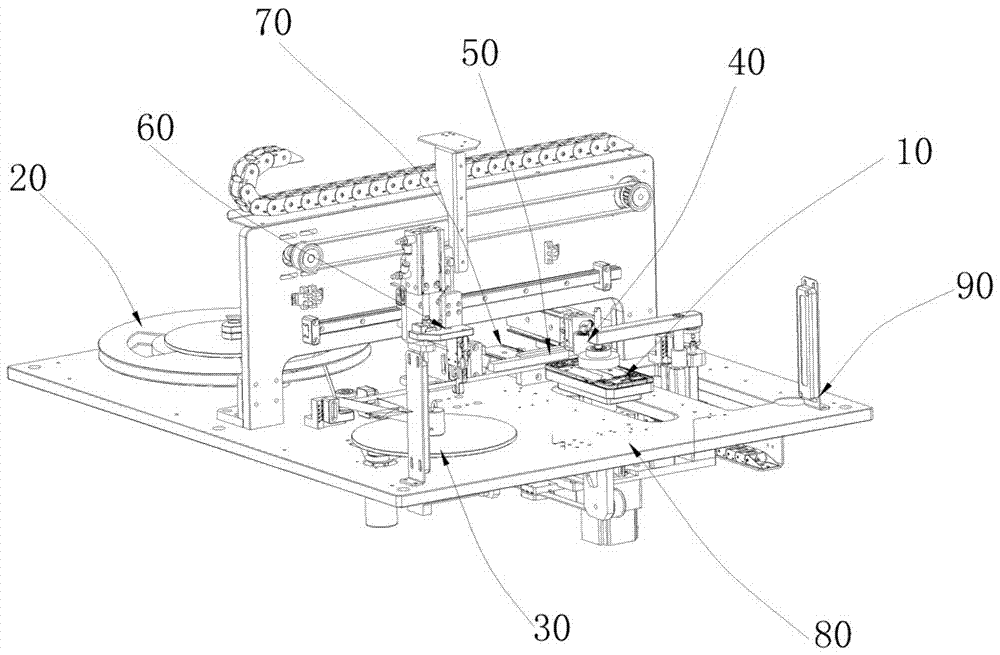

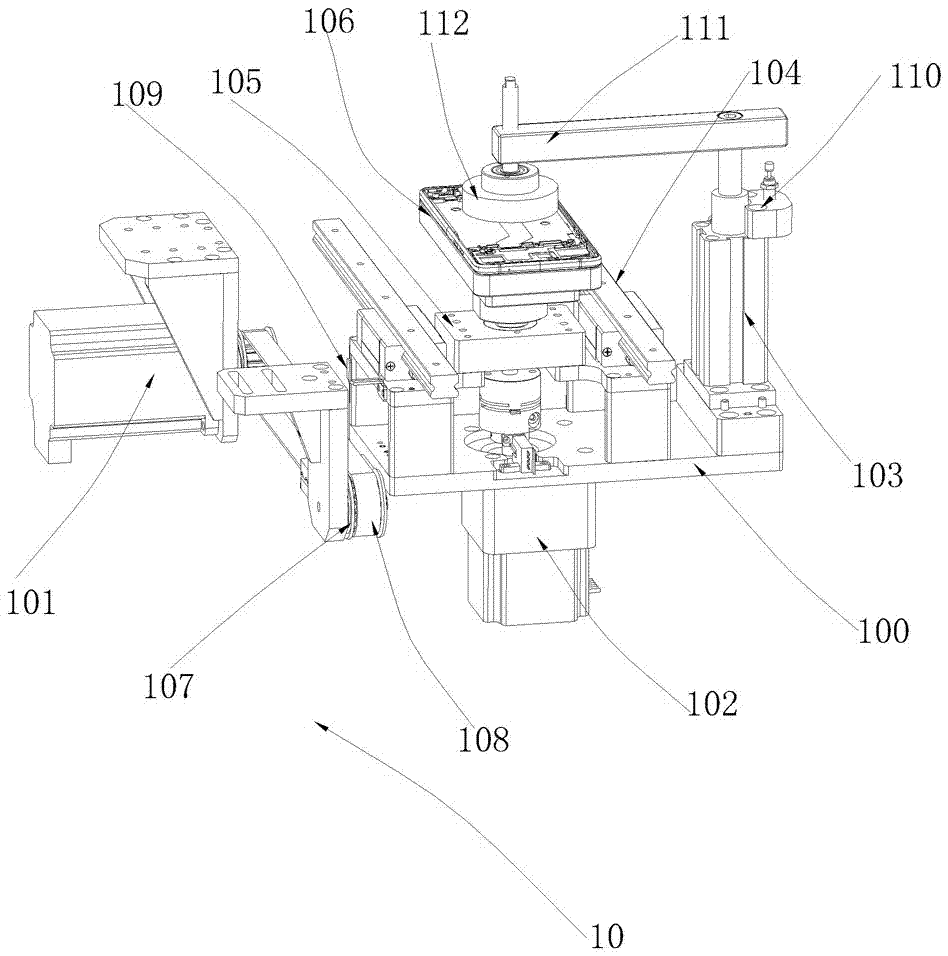

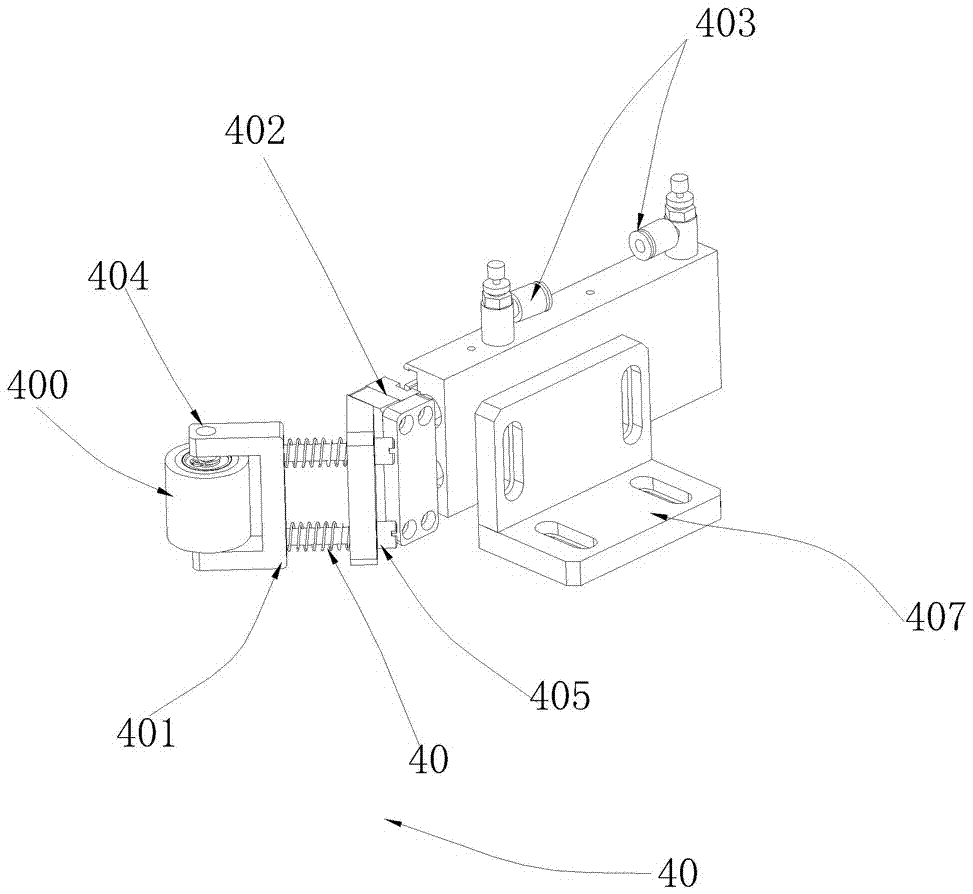

[0051] see figure 1 , the general-purpose equipment that the mobile phone frame that the present invention provides is automatically pasted protective film, comprises the sliding platform mechanism 10 that is used to realize the mobile phone frame feed motion and rotary motion, is used for the feeding mechanism 20 that protective film is fed, is used for collecting The receiving mechanism 30 for the bottom film of the protective film, the film rolling mechanism 40 for rolling and laminating the protective film and the frame of the mobile phone, the film pressing mechanism 50 for pressing the protective film on the frame of the mobile phone, and the film pressing mechanism 50 for clamping the protective film The clamping mechanism 60 of the film and the film cutting mechanism 70 for cutting off the protective film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com