Multiunit cubesat main load-bearing structure

A multi-unit, cubic technology, applied in the field of multi-unit cube star main load-bearing structure, can solve problems such as jamming, launch failure, parallelism cannot be guaranteed, etc., to ensure successful launch, improve integrity, and ensure parallelism Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

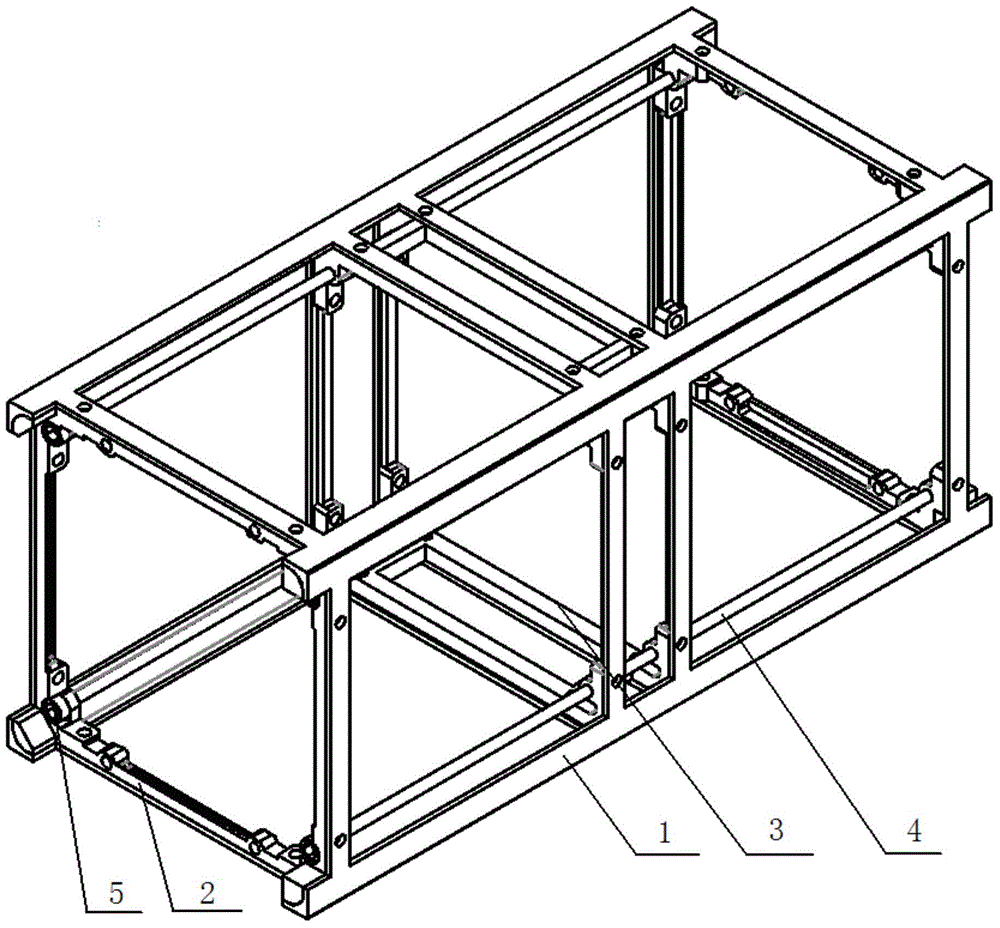

[0019] combine figure 1 :

[0020] A main load-bearing structure of a double-unit cube star, including a main frame 1, an end cover 2, an intermediate frame 3, a screw rod 4 and a nut 5, and the middle part in the long side direction is set to be the same as the cross-sectional shape of the main frame 1 in the long side direction. The matching ribs, the end covers 2 are arranged at both ends of the main frame 1 along the long side direction, and its shape matches the shape surrounded by the main frame 1, and the middle frame 3 is arranged at the position corresponding to the inner ribs of the main frame 1, Its shape matches the shape surrounded by ribs, and the end cover 2 and the middle frame 3 are in clearance fit with the main frame 1; four screws 4 are arranged in the main frame 1 along the long side direction, and the screws 4 pass through the middle frame 3 and the main frame 1. One of the end caps 2, its two ends are fixedly connected with the other end cap and the nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com