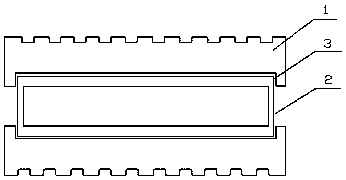

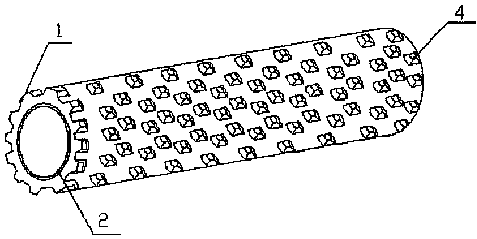

A kind of preparation method of wolf tooth yoga column

A wolf tooth yoga and raw material technology, which is applied in the field of rubber and plastic products, can solve the problems of large differences in hardness of the surface pattern of finished products, shorten the service life of yoga columns, and low utilization rate of raw materials, etc., and achieve short production cycle, low cost and high utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

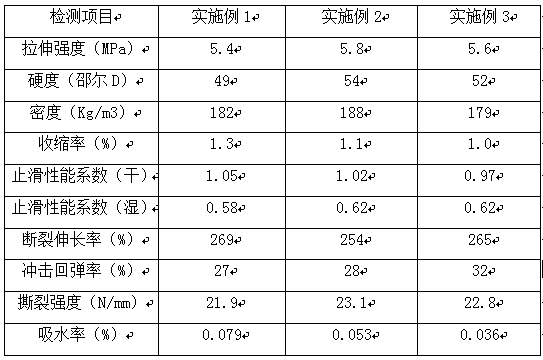

Embodiment 1

[0037] A kind of preparation method of wolf tooth yoga column described in the present embodiment, comprises the following steps:

[0038] (1) Prepare raw materials: the mass components are: ethylene-vinyl acetate copolymer: 85 parts, sodium bicarbonate: 12 parts, modified sepiolite: 13 parts, 2-mercaptobenzothiazole: 4 parts, Borax: 7 parts, sulfur: 1 part, N-isopropyl-N'-phenyl-p-phenylenediamine: 2 parts, pigment: 4 parts;

[0039] (2) The preheating temperature of the internal mixer is 75°C, put the raw materials into the internal mixer for 22 minutes, the internal mixing temperature is 115°C, and the pressure is 7KG / M 2 Stir the raw material evenly, melt and discharge the material under the condition that the internal mixer rotating speed is 55rpm;

[0040] (3) Put the raw materials after step (2) into a screw extruder at a temperature of 112°C for plasticization, extrude, and air-cool and pelletize through a die to obtain mixture particles, the particle size of which is...

Embodiment 2

[0049] A kind of preparation method of wolf tooth yoga column described in the present embodiment, comprises the following steps:

[0050] (1) Prepare raw materials: the mass components are: ethylene-vinyl acetate copolymer: 80 parts, azodicarbonamide: 15 parts, nanostructured white carbon black: 10 parts, tetramethylthiuram disulfide: 5 parts Parts, stearic acid: 5 parts, sulfur monochloride: 2 parts, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester: 1 part, pigment: 5 parts ;

[0051] (2) The preheating temperature of the internal mixer is 70°C, put the raw materials into the internal mixer for 30 minutes, the internal mixing temperature is 110°C, and the pressure is 8KG / M 2 Under the condition that raw material is stirred evenly, melts and discharges, the internal mixer rotating speed is 50rpm;

[0052] (3) Put the raw materials after step (2) into a screw extruder at a temperature of 115°C to plasticize, extrude, and air-cool and pelletize...

Embodiment 3

[0061] A kind of preparation method of wolf tooth yoga column described in the present embodiment, comprises the following steps:

[0062] (1) Preparation of raw materials: its mass components are: ethylene-vinyl acetate copolymer: 95 parts, N,N′-dinitrosopentamethylenetetramine: 8 parts, modified kaolin: 15 parts, dibutyl Zinc dithiocarbamate: 2 parts, magnesium oxide: 10 parts, ethyl carbamate: 1 part, N-isopropyl-N'-phenyl-p-phenylenediamine: 2 parts, pigment: 3 parts;

[0063] (2) The preheating temperature of the internal mixer is 80°C, put the raw materials into the internal mixer for 15 minutes, the internal mixing temperature is 120°C, and the pressure is 5KG / M 2 Stir the raw materials evenly, melt and discharge the raw materials under certain conditions, and the mixer speed is 60rpm;

[0064] (3) Put the raw materials after step (2) into a screw extruder at a temperature of 110°C to plasticize, extrude, and air-cool and pelletize through a die to obtain mixture granu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com