Sensing adhesive tape with high-temperature strain detecting function

A high-temperature strain and tape technology, used in adhesives, measuring devices, film/sheet adhesives, etc., can solve the problem that strain sensors are susceptible to electromagnetic interference, cannot be used in flammable and explosive environments, and the components under test are damaged, etc. problem, to achieve the effect of non-destructive flexible detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

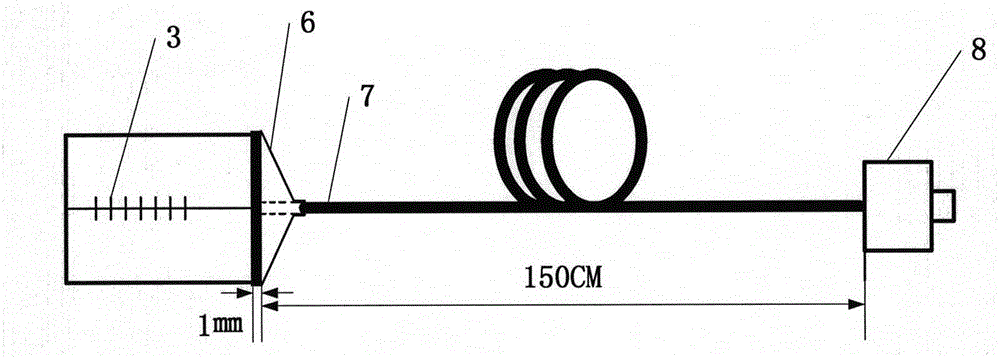

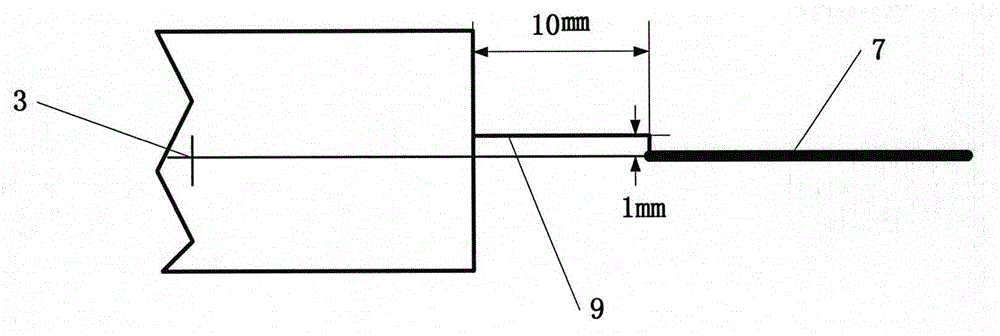

[0023] The following will be combined with Figures 1 to 5 The present invention is described in further detail with the specific embodiment:

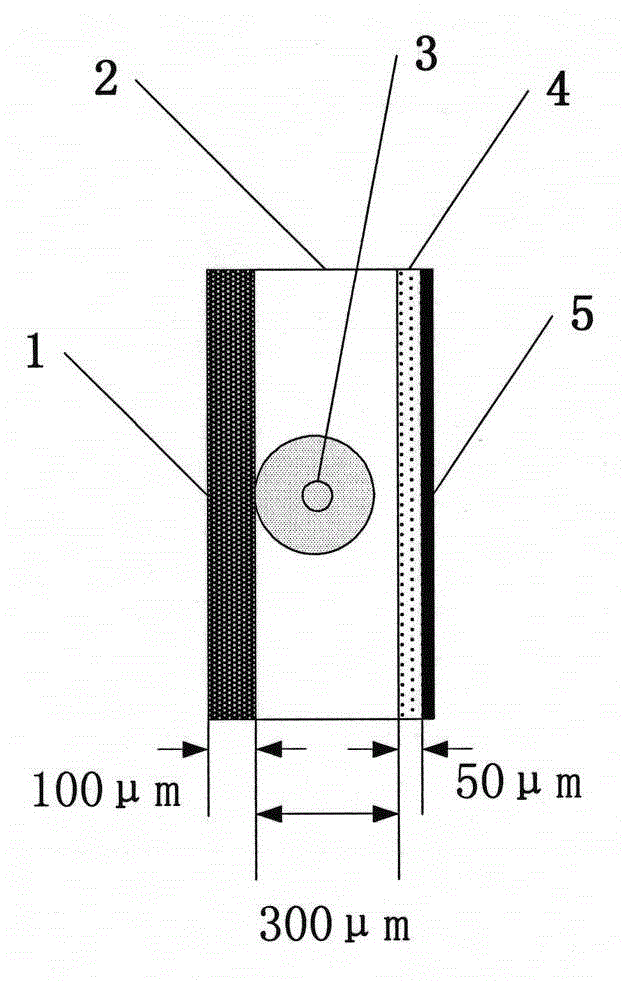

[0024] The right view of a sensor tape with high-temperature strain detection function is as follows figure 2 As shown, it includes a tape substrate composed of imported glass fiber cloth (1) with a thickness of 100 μm and Teflon resin (2) (polytetrafluoroethylene resin) with a thickness of 300 μm, and the total thickness of the substrate is 400 μm; Teflon The dragon resin contains a polymer-coated fiber grating (3) that can withstand a high temperature of 250°C for a long time. The fiber grating is a standard size high-temperature-resistant fiber grating, that is, the cladding diameter is 125 μm, and the polyimide coating layer is 155 μm.

[0025] Through the one-dimensional or two-dimensional layout of high-temperature fiber gratings, the one-dimensional or two-dimensional strain detection function on the surface of high-temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com