A low-tangling impeller, a low-tangling washing machine and a low-tangling washing method

A low winding, pulsator technology, applied in pulsator and washing machine, low winding pulsator and washing machine and low winding washing field, can solve the problems of reducing winding, user troubles, difficult to separate and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

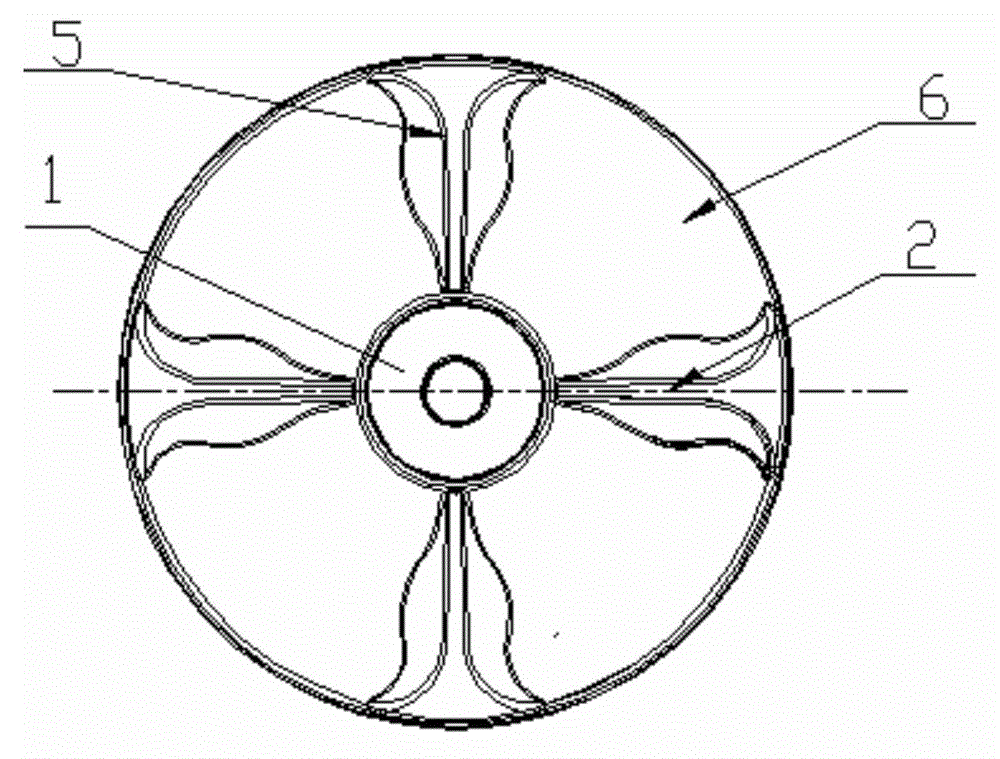

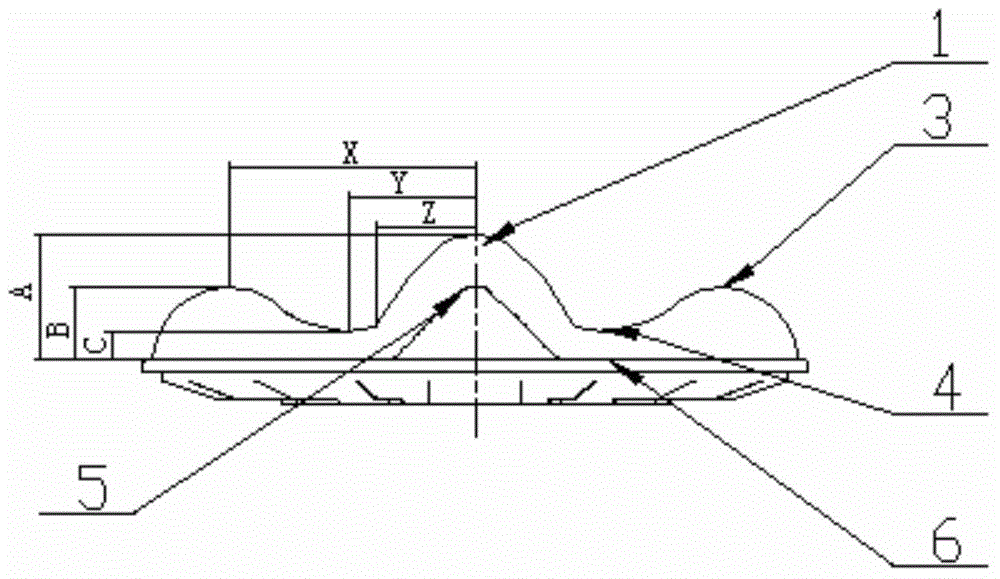

[0027] Such as figure 1 As shown, a low-winding pulsator includes a wheel seat, a central protrusion 1 arranged on the wheel seat, and ribs 2 connected to the central protrusion 1 and evenly distributed on the wheel seat around the circumference of the wheel seat. The ribs include the convex rib in the middle and the arc surface on both sides of the rib connecting the top of the rib and the upper surface of the wheel seat. The arc surfaces on both sides are symmetrically distributed. The bottom of the arc surface is large and gradually converges upward. The rib is located on the periphery of the wheel seat The end portion of the rib gradually expands from the middle to both sides, and the number of ribs is 3-6. In this embodiment, the number is 4.

[0028] Such as figure 1 As shown, viewed from a direction parallel to the central axis of the wheel seat, the arc bottoms on both sides of the rib narrow from the periphery of the wheel seat to the center of the wheel seat. The i...

Embodiment 2

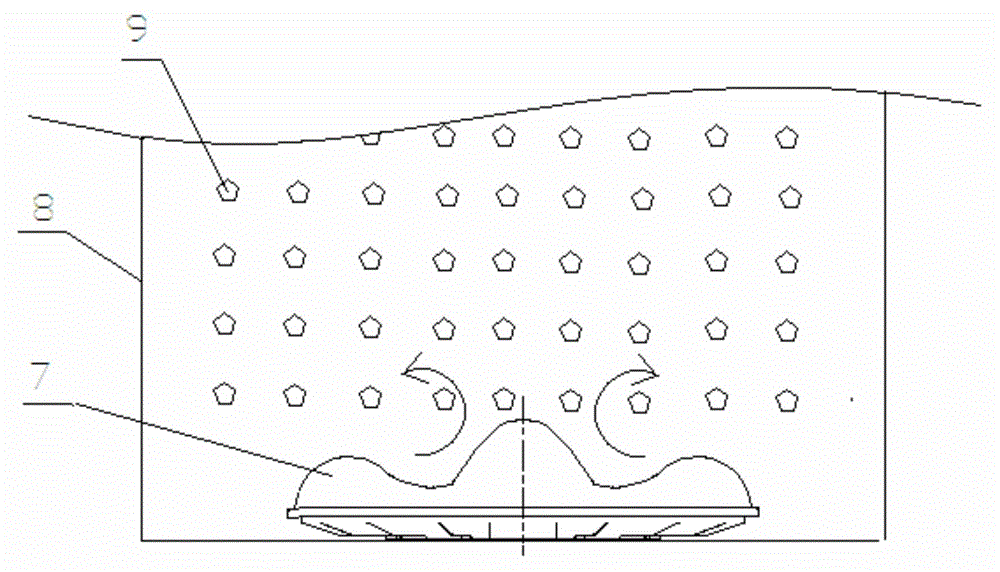

[0042] A low-entanglement washing machine is equipped with the pulsator mentioned in the first embodiment. During laundry, with the rotation of the pulsator 7, the clothes are in the inner tub 8 of the washing machine and protrude from the periphery of the pulsator to the center of the center of the pulsator. Move up and climb up along the central protrusion, then move towards the inner barrel 8, move down to the bottom of the inner barrel along the inner barrel, climb up from the periphery of the pulsator to the central protrusion of the pulsator, and repeat the above actions. Since the wheel seat of the pulsator is provided with a central protrusion and a rib, and the position of the rib near the central protrusion is low, and the position away from the central protrusion is high, forming an arc-shaped curve with a high outside and a low inside, and it is opposite to the convex rib. The position of the highest point, the position of the lowest point where the raised rib is cl...

Embodiment 3

[0045] A low-entanglement washing method described in this embodiment adopts the washing machine described in Embodiment 2. When the pulsator of the washing machine rotates, the single rotation time of the pulsator is 0.6-1 second. The rotation time is 0.8 seconds.

[0046] The stop time between two rotations is less than 0.6 seconds. Considering the different transmission modes of the washing machine, the washing machine based on the direct drive mode should minimize the stop time as much as possible; the washing machine using the brushless DC motor (BLDCMOTOR) and the washing machine driven by the deceleration device is preferably 0.3 seconds; the belt drive mode is preferably 0.4 seconds. In this embodiment, a washing machine using a brushless DC motor (BLDCMOTOR) driven by a deceleration device is selected for washing, and the stop time between two rotations is 0.3 seconds.

[0047] The invention provides a low-entanglement washing method, which further optimizes and limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com