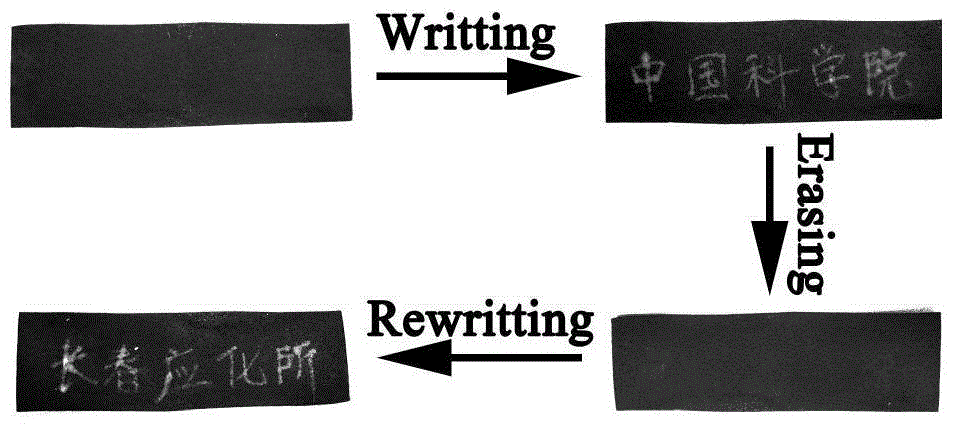

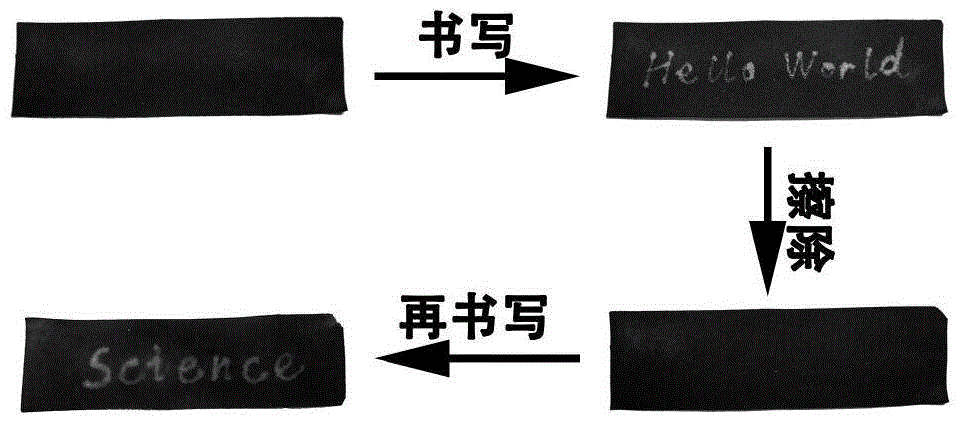

Polyacid-based rewritable paper and preparation method thereof

An acid solution, polyethylene glycol technology, used in papermaking, paper coatings, textiles and papermaking, etc., can solve problems such as expensive, unstable discoloration process of rewritable paper, and toxic materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention firstly provides a kind of preparation method based on polyacid rewritable paper, comprising:

[0026] Step 1: Mix the polyacid solution with the alcohol solution to obtain a mixed solution, add the mixed solution into a quartz cell, and irradiate the mixed solution with a high-pressure mercury lamp to obtain a reduced polyacid solution;

[0027] Step 2: Add polyethylene glycol to the reduced polyacid solution obtained in step 1 to obtain the reduced polyacid solution of polyethylene glycol, and smear the polyethylene glycol solution, polyethylene glycol reduced polyacid solution on the cellulose filter paper successively. Prototype polyacid solution and polyethylene glycol solution, and drying at 40-90°C respectively to obtain polyacid-based rewritable paper.

[0028] According to the present invention, the polyacid solution is mixed with the alcohol solution to obtain a mixed solution, the mixed solution is added in a quartz cell, and the mixed s...

Embodiment 1

[0037] Mix 10mM silicomomolybdic acid solution and isopropanol aqueous solution at a volume ratio of 1:4, add it to a 1cm quartz cell, and irradiate it under a high-pressure mercury lamp (emission light 365nm, power 10-1000W) until the color of the solution turns dark blue , to obtain the reduced polyacid;

[0038] Polyethylene glycol 2000 was added to the obtained reduced polyacid solution to obtain a 5% polyethylene glycol 2000 reduced polyacid solution, which was evenly spread on cellulose filter paper with a mass fraction of 10%. Ethylene glycol 20000 solution, and dry at 70 for 1 hour, so that the surface of the cellulose paper is uniformly covered with a layer of PEG film; then, 5% polyethylene glycol 20000 reduced polyacid solution is evenly spread on the cellulose paper surface, and dried at 70°C for 1 hour; finally, a layer of 10% polyethylene glycol 20,000 solution was uniformly applied on the surface of the above-mentioned paper as a protective layer, and dried at 7...

Embodiment 2

[0044] Mix 1mM phosphomolybdic acid solution and methanol aqueous solution at a volume ratio of 1:2, add it to a 1cm quartz cell, and irradiate it under a high-pressure mercury lamp (emitted light 365nm, power 10-1000W) until the color of the solution turns dark blue, that is get reduced polyacid;

[0045] Polyethylene glycol 2000 is added in the reduced polyacid solution that obtains, and the polyethylene glycol 2000 reduced polyacid solution that obtains mass fraction is 2%, smears mass fraction evenly on the cellulose filter paper and is 5% polyacid solution. Ethylene glycol 20,000 solution, and dried at 40°C for 3 hours, so that the surface of the cellulose paper is evenly covered with a layer of PEG film; then, the mass fraction of 2% polyethylene glycol 20,000 reduced polyacid solution is evenly spread on the fiber Plain paper surface, and dry at 40°C for 3 hours; finally, apply a layer of 5% polyethylene glycol 20,000 solution evenly on the surface of the paper obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com