Combined exhaust pipe for solid rocket engine

A technology of solid rockets and engines, which is applied in the direction of rocket engine devices, machines/engines, mechanical equipment, etc., can solve uneconomical problems and achieve the effects of saving costs, ensuring versatility, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

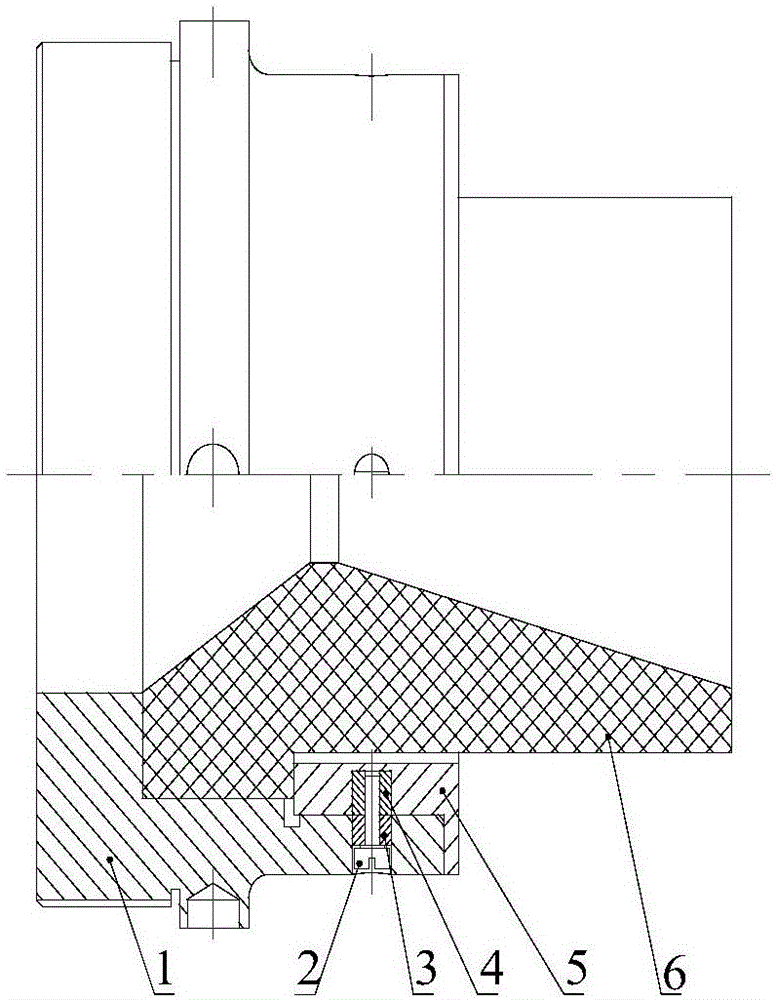

[0012] combine figure 1 :

[0013] A combined nozzle of a solid rocket motor in the present invention, comprising: a nozzle base 1, a Laval tube 6, an annular gland 5, a safety pin 2 and a shear sleeve, and the Laval tube 6 is placed in the cavity of the nozzle base 1 , and is limited by the inner end surface of the nozzle base 1 and the annular gland 5 at both ends, the annular gland 5 is positioned by the safety pin 2 that passes through the nozzle base 1 and extends into the annular gland 5, the safety pin 2 and the nozzle A shearing sleeve is arranged between the pipe base 1 and the annular gland 5 .

[0014] One end of the Laval tube 6 is placed in the nozzle base 1, and the end surface of the contracting section is limited by the inner end surface of the nozzle base 1. The outer circumference of the Laval tube 6 has an annular boss, and the end surface of the annular boss is covered by the ring gland 5. End limit.

[0015] There is an annular boss on the outer periphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com