Brake

A technology of brakes and brake discs, applied in the mechanical field, can solve problems such as defects in the heat dissipation design of the brakes and short service life, and achieve the effect of ensuring lubrication and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

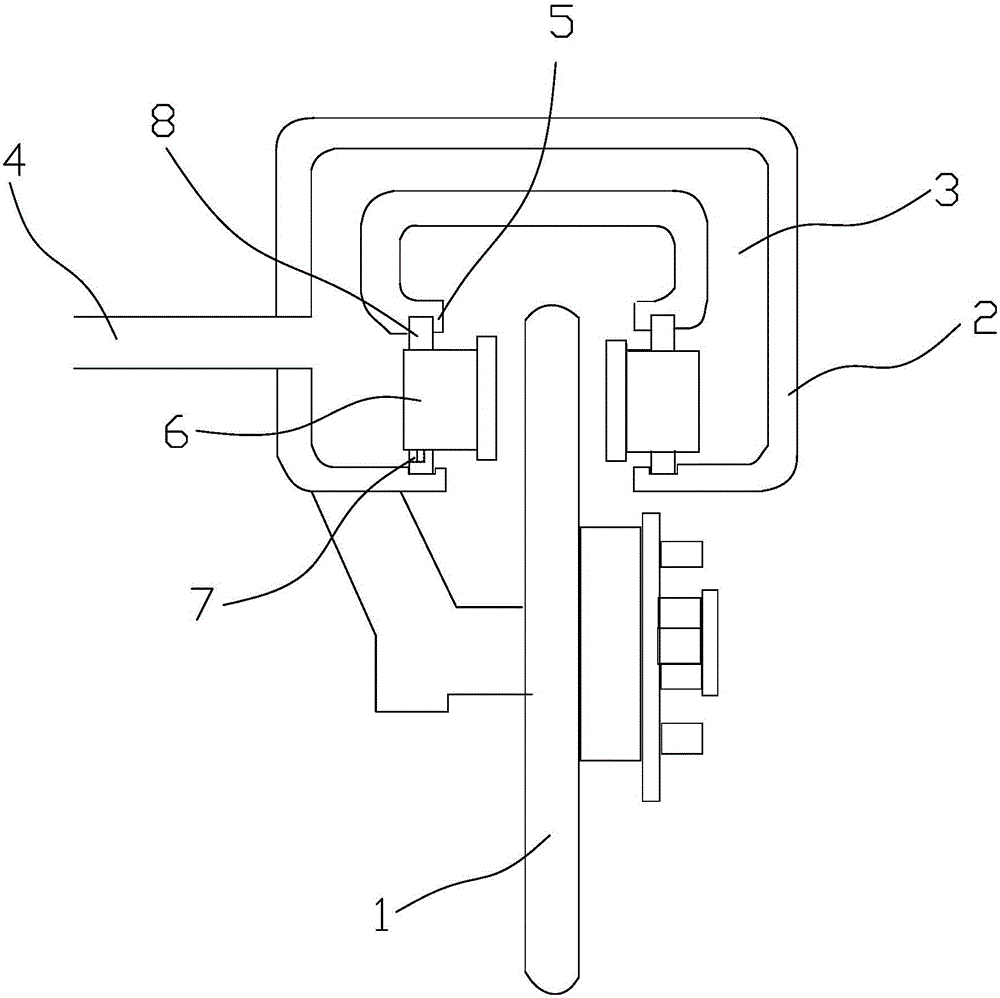

[0009] Such as figure 1 As shown, the present invention proposes a brake, including a brake disc 1 fixed to the hub and a brake caliper 2 fixed to the axle. The brake caliper 2 includes an oil chamber 3, an oil inlet 4 and 1 The piston port 5 on the side, the piston port 5 is sleeved with a piston 6, and the piston sleeve 8 is arranged between the piston 6 and the piston port 5. It communicates with the oil chamber 3 or the lubricating assembly.

[0010] A brake proposed by the present invention uses a hydraulic method to push the piston 6 to the rotating brake disc 1 to achieve the purpose of braking. The lubricating port 7 formed or communicated with the oil chamber 3 can store oil during use to ensure the lubrication between the piston 6 and the piston sleeve 8, effectively prolonging the service life of the piston 6.

[0011] Preferably, the number of moistening ports 7 is four.

[0012] Further, the 4 lubricating ports 7 are evenly distributed on the mating surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com