Needle cylinder self-lubricating type circular knitting machine for feather yarn production

A circular knitting machine and self-lubricating technology, which is applied in the fields of knitting, textiles and papermaking, can solve the problems of unfavorable automatic production of feather yarn, reduce the functionality of circular knitting machine, and affect the quality of feather yarn forming, so as to reduce manual participation and improve The degree of automation and intelligence, the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

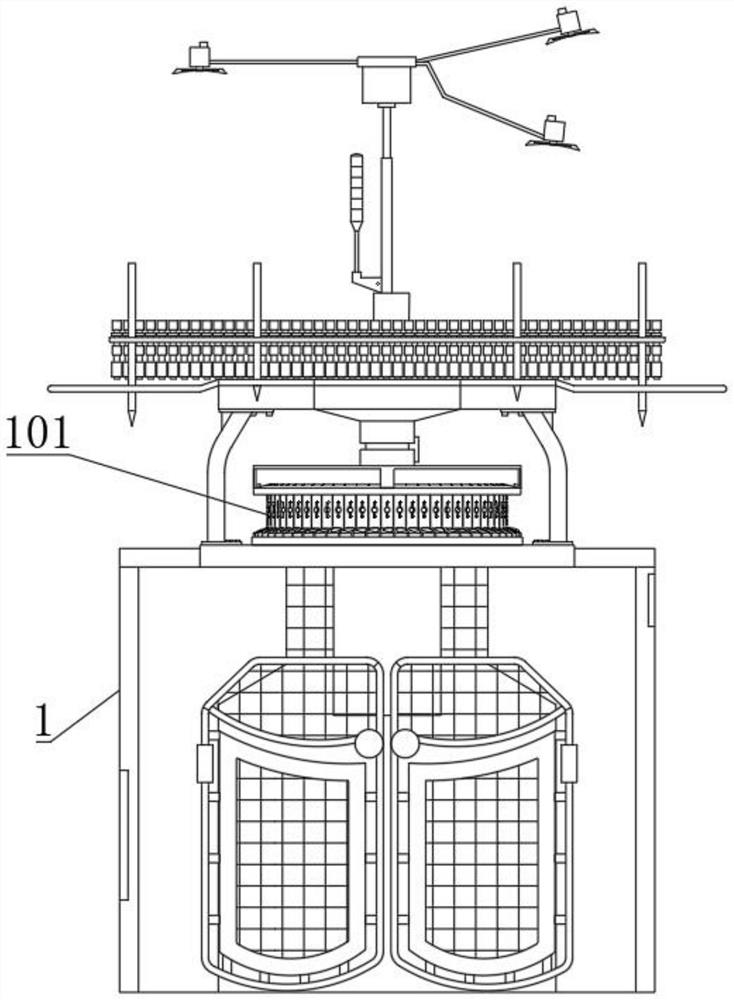

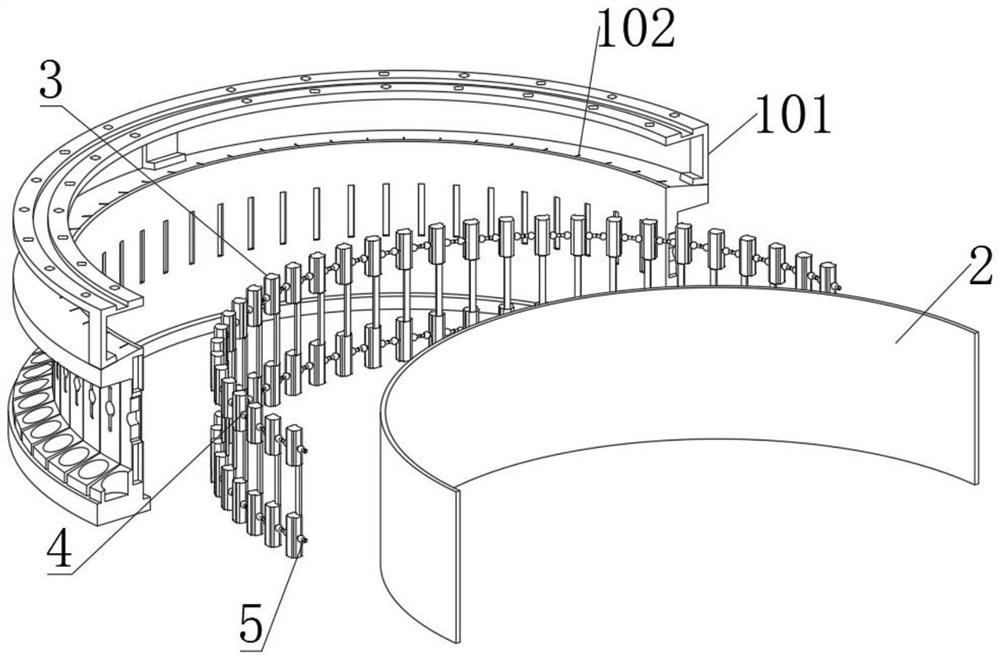

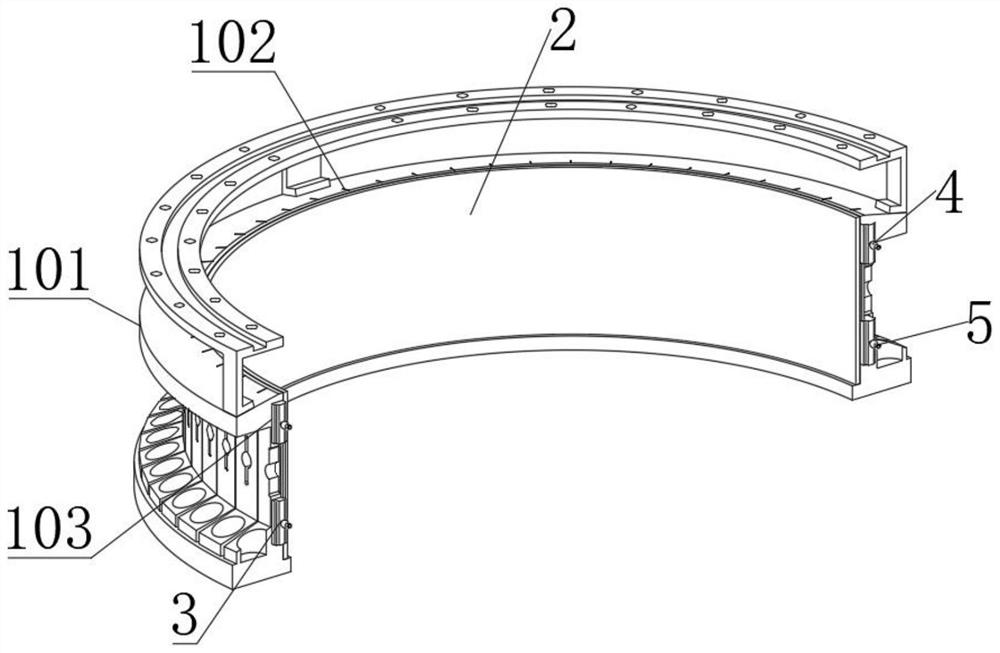

[0042] see Figure 1-10 , a cylinder self-lubricating circular knitting machine for feather yarn production, comprising a self-lubricating needle cylinder 101 installed on a circular knitting machine body 1, a plurality of knitting chute 102 is provided on the self-lubricating needle cylinder 101, and the self-lubricating needle A plurality of self-lubricating chambers 103 are opened in the cylinder 101, and a single self-lubricating chamber 103 is located between two knitting chutes 102. An oil equalizing assembly 3 is arranged in the self-lubricating chamber 103, and the oil equalizing assembly 3 is close to the adjacent knitting chute. One side of the groove 102 is fixedly connected with a segmented oil storage case 4, and the segmented oil storage case 4 is fixedly connected with a segmented oil storage bag 401 matched with the oil equalizing assembly 3, and the segmented oil storage case 4 is close to One end of the knitting chute 102 is fixedly connected with a self-lubr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com