hub reducer

A technology of hub reducer and hub, which is applied in the direction of wheel, gear lubrication/cooling, belt/chain/gear, etc. It can solve the problems affecting vehicle design layout, large power loss, and short battery life, so as to save lateral space and prolong Effect of service life, improvement of lubricating effect and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

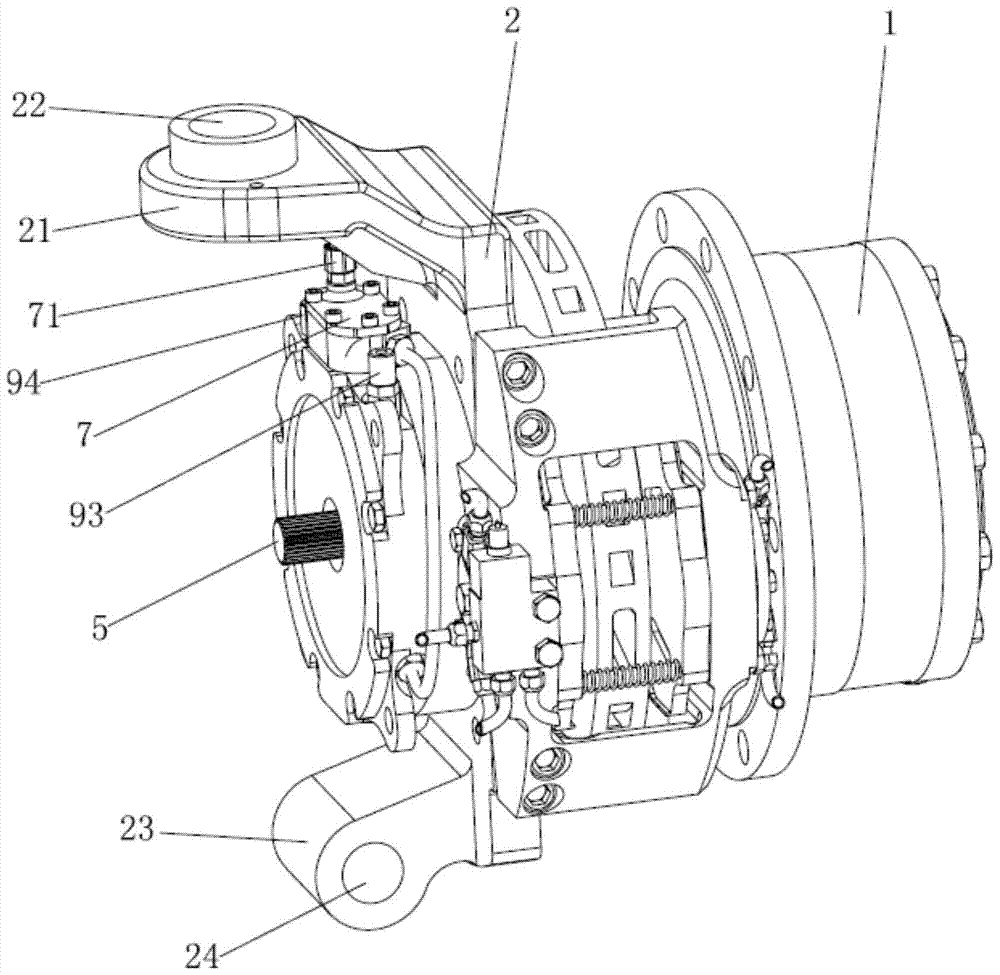

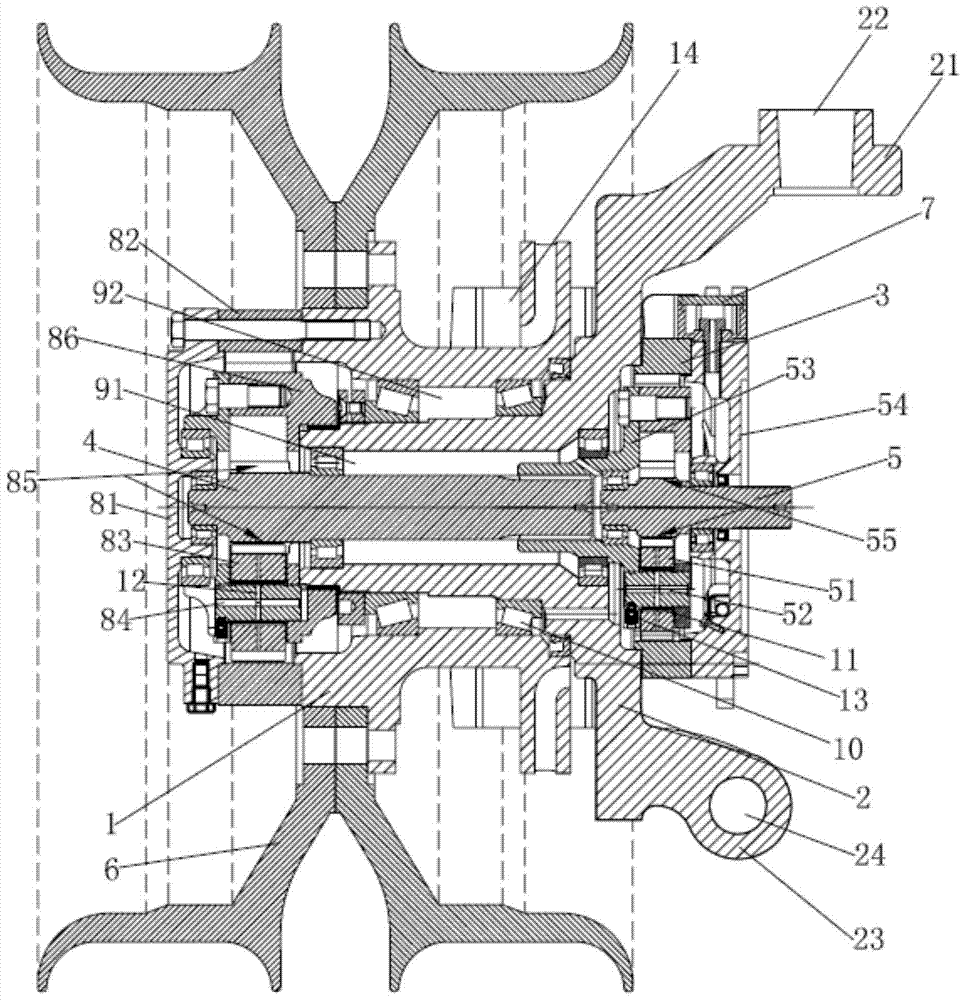

[0018] The present invention will be further described below in conjunction with accompanying drawing.

[0019] Depend on figure 1 and figure 2 As shown, the present invention is composed of a hub 1 and the like. A fixed bracket 2 is provided on one side of the hub 1. The middle part of the fixed bracket 2 is a ring structure, and the ring structure is nested and fixed on one side of the hub 1. , the upper end of the fixed bracket 2 is provided with a first connecting bracket 21 protruding outwards, a section of step column is vertically provided at the protruding end of the first connection bracket 21, and a step column is arranged in the middle of the step column. The first connection hole 22 ; the lower end of the fixing bracket 2 is provided with a second connection bracket 23 protruding outwards, and a second connection hole 24 is horizontally provided at the protruding end of the second connection bracket 23 .

[0020] A first reduction gear is arranged inside the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com