Positioning and supporting structure of helical planetary gearbox for pure electric passenger car

A technology for positioning support structure and planetary reduction box, applied in the direction of transmission parts, belt/chain/gear, mechanical equipment, etc., can solve the problems of unstable support of the sun gear assembly, large structure size, axial movement, etc. Achieve the effect of favorable structural arrangement, compact structure, and prevention of axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

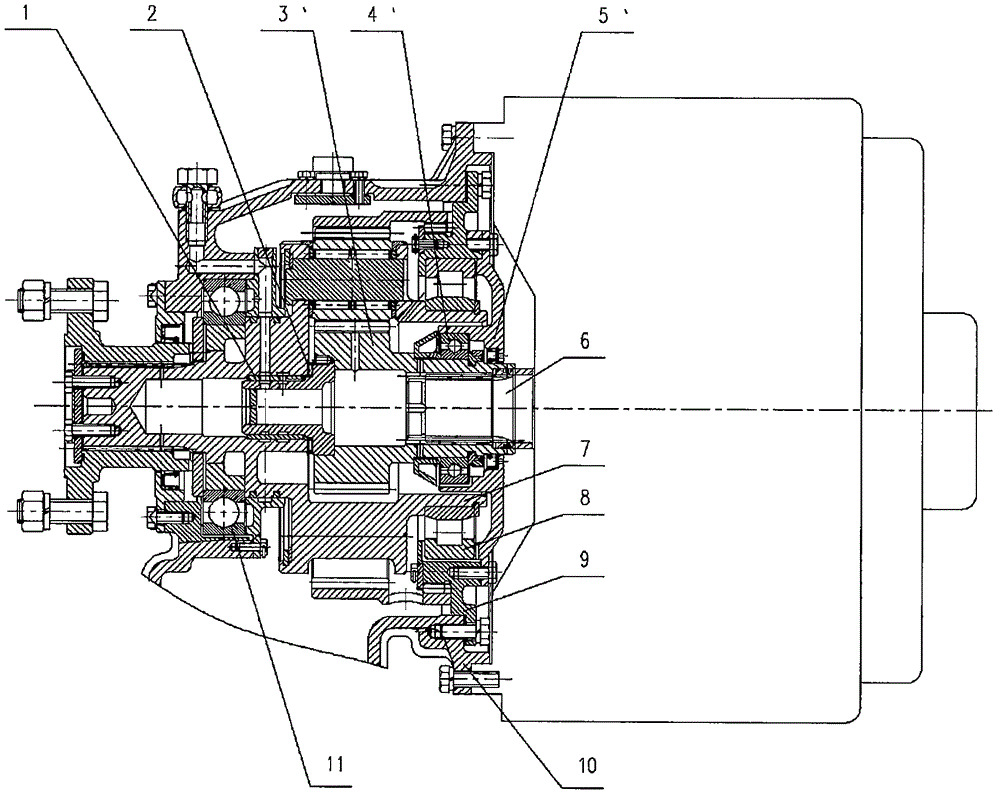

[0008] Such as figure 1 As shown, the present invention is a positioning support structure for a helical planetary gearbox for a pure electric bus, including a sliding bearing 1, a thrust bearing 2, a sun gear assembly 3, a deep groove ball bearing 4, a support seat 5 and a frame 7, and the sliding bearing 1 is press-fitted in the inner hole of the output end of the frame 7 and fixed into a rigid whole. The inner hole of the sliding bearing 1 and the journal on the left side of the sun gear assembly 3 (that is, the output end) adopt clearance fit, and the right end of the sun gear assembly 3 (input end) end) through the spline and the power motor 6 to form a rigid whole, forming a two-point stable support; the deep groove ball bearing 4 is installed on the journal on the right side (input end) of the sun gear assembly 3, and the outer ring of the bearing and the inner support seat 5 There is a large gap between the holes to prevent radial over-positioning, so that the sun gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com