A lining installation process of an industrial furnace

An installation process and an industrial furnace technology, applied in lining repair and other directions, can solve the problems of low cotton packing density, many hammering times, and many processes, and achieve the effect of guaranteed packing density, simple and clear process, and safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

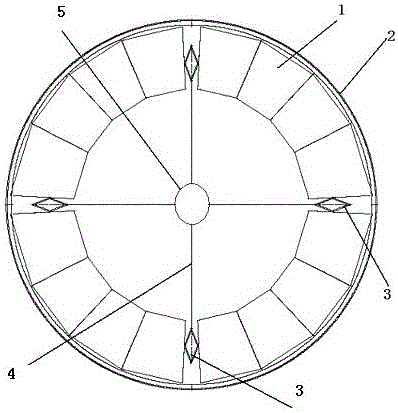

[0014] A furnace lining installation process for an industrial furnace, which includes the following steps: ① place the cube-shaped cotton blocks 1 close to the inner side 2 of the furnace wall, and insert a jack 3 when there are about five cotton blocks in each layer; Arrange the cotton blocks in the circle close to the furnace wall according to the arrangement in step 1, start the jack, and press the two ends of the jack to squeeze the cotton blocks on both sides respectively; Insert the cotton block, then start the adjacent jack to continue to squeeze, fill in the cotton blocks in each gap position in turn, and squeeze the cotton block from the gap in the last gap position, or use an auxiliary Tools, such as a pressing plate, are used to press the cotton block tightly, and a cutter can also be used to cut the cotton block, which is convenient for use; the jacks described are diamond jacks; each diamond jack is connected with the hand ring 5 by a steel wire stay rope 4 .

Embodiment 2

[0016] A furnace lining installation process for an industrial furnace, which includes the following steps: ① place the cube-shaped cotton blocks close to the furnace wall, and insert a jack when there are about seven cotton blocks in each layer; ② put the inner side of the furnace wall close to the furnace wall Arrange the cotton blocks according to the arrangement method in step 1, start the jack, and press the two ends of the jack to squeeze the cotton blocks on both sides; Then start the adjacent jack and continue to squeeze, and fill in the cotton blocks in each gap position in turn, and squeeze the cotton block from the gap in the last gap position. You can also use auxiliary tools, such as a pressing plate. Said that the cotton block is tightly plugged and pressed in, and a cutter can also be used to cut the cotton block, which is convenient for use; the jacks described are rhombus jacks; each rhombus jack is connected with the hand-held ring by a steel wire pull rope. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com