Mixing channel cigarette checking system

A cigarette and aisle technology, which is applied in the field of mixed aisle cigarette checking system, can solve the problems of high labor intensity, low labor intensity, and sorting errors for distributors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

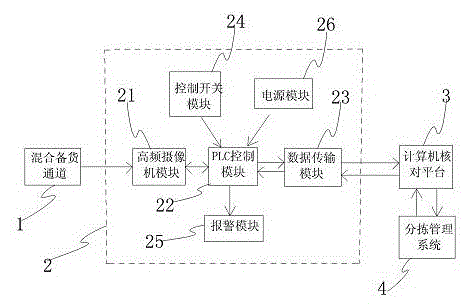

[0012] refer to figure 1 , the embodiment of the present invention discloses that a mixed channel cigarette checking system includes a mixed stocking channel 1, an information collection box 2, a computer checking platform 3 and a sorting management system 4, and the computer checking platform 3 communicates with the sorting management system through the network The management system 4 is connected, and the information collection box 2 is arranged on the mixed stocking channel 1, and the information collection box 2 includes a high-frequency camera module 21, a PLC control module 22, a data transmission module 23, a control switch module 24, and an alarm module 25 And power supply module 26, described high-frequency camera module 21 is connected with PLC control module 22, and the photographing executive end of described high-frequency camera module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com