Sliding installation structure of marine electronic control module

A technology of electronic control module and installation structure, which is applied in the direction of support structure installation, rack/frame structure, etc., which can solve the problems of ineffective use of cabinet internal space, unfavorable overall structure and volume simplification, and lack of limit structure in guide rail structure and other issues to achieve the effect of ensuring operability and safety, facilitating cabinet maintenance, and avoiding complications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

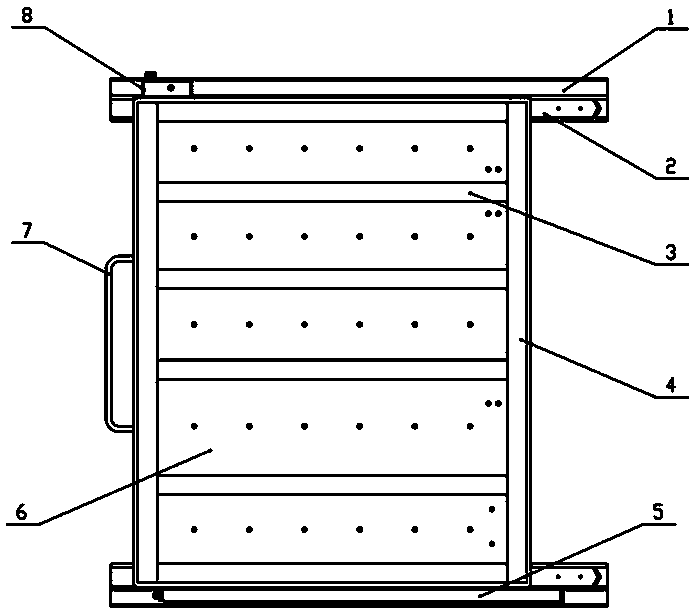

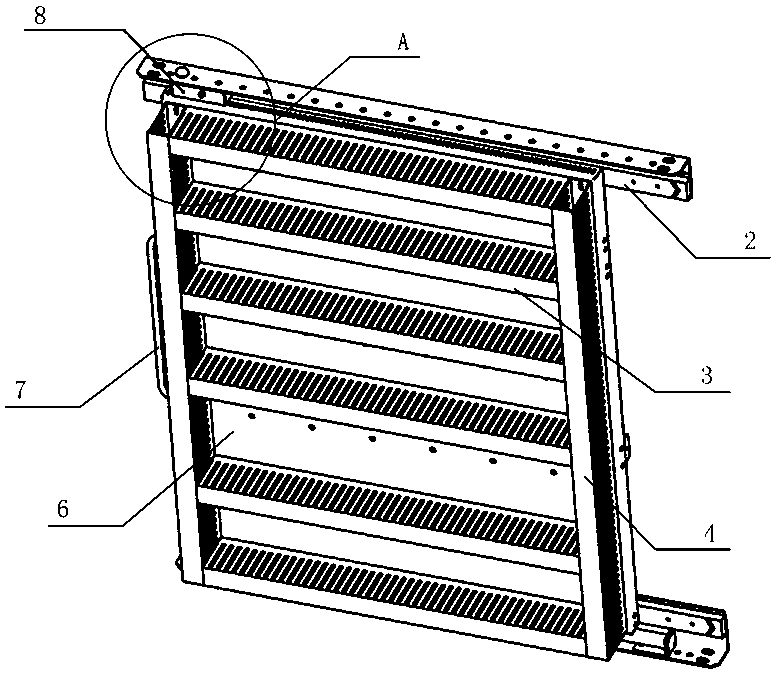

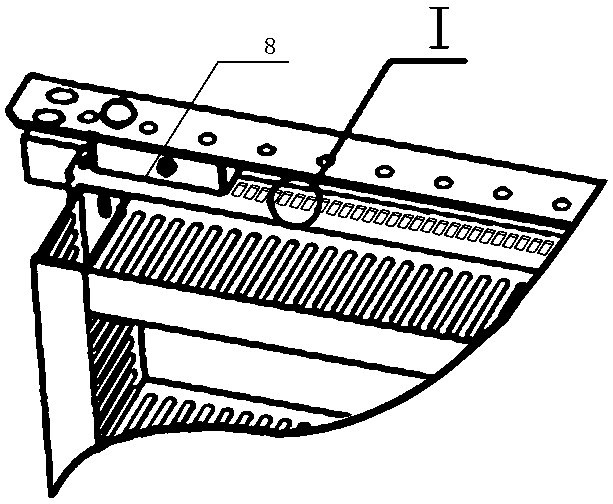

[0064] As another typical specific embodiment of the present invention, a sliding installation structure of a marine electronic control module includes:

[0065] Electric control module, no less than two module mounting plates 1 for installing the electric control module inside the cabinet, and the same number of guide rails 2 as the module mounting plate 1, the guide rails 2 are connected with the module mounting plate 1, and the guide rails respectively set on the upper part and the lower part of the electronic control module;

[0066] The electronic control module further includes:

[0067] The bottom plate 10 is connected to the module mounting plate 1 through the guide rail 2, and the bottom plate 10 is arranged between the upper and lower guide rails 2 of the electronic control module, and can slide along the guide rail 2;

[0068] Several screw holes are set on the side of the module mounting plate 1. When the electronic control module is pushed into the cabinet body t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com