Throttling booster conveying device for fire truck

A pressurized conveying and fire truck technology, applied in fire rescue, etc., can solve the problems of insufficient airflow pressure, deposition on the hose wall, and ineffective fire extinguishing effect, to ensure concentration, improve regulation efficiency, and small impact resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

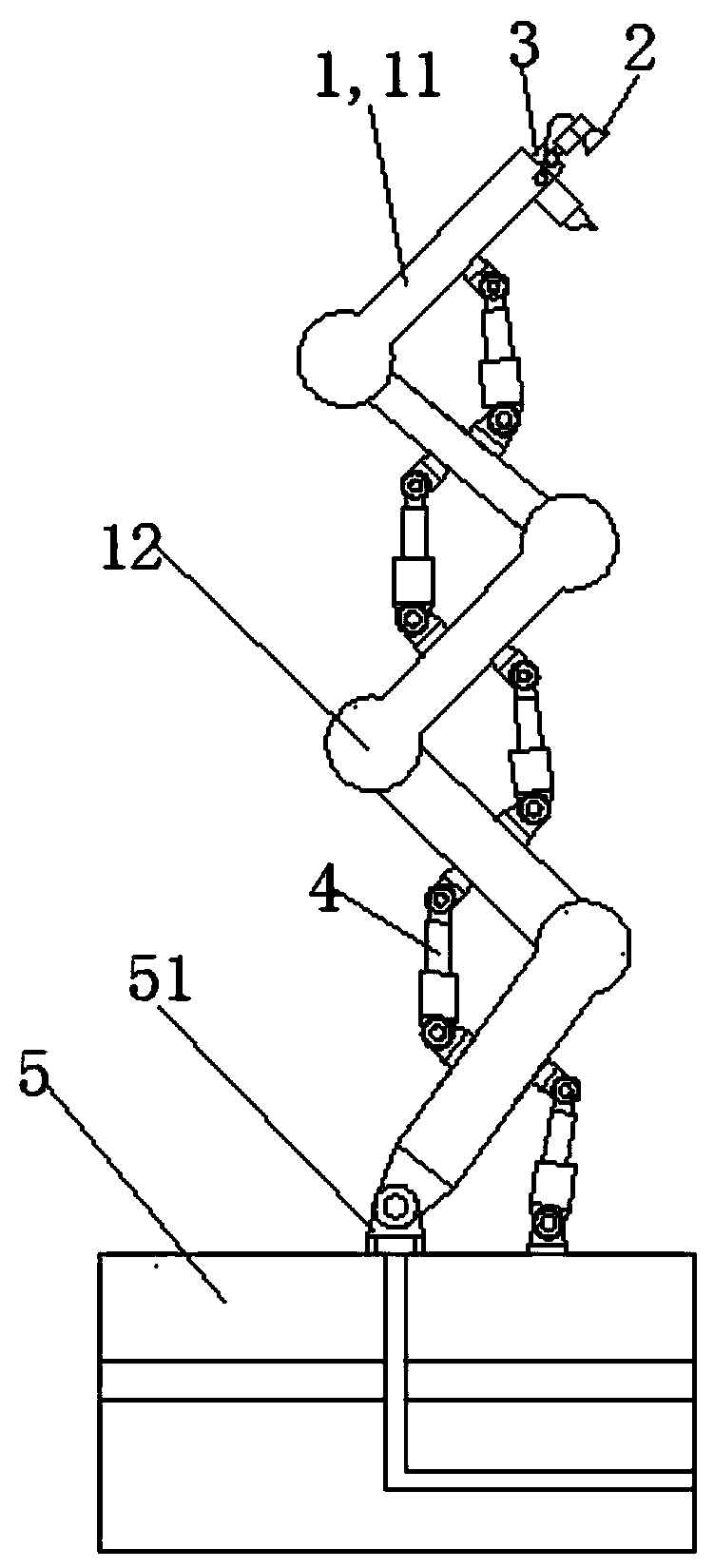

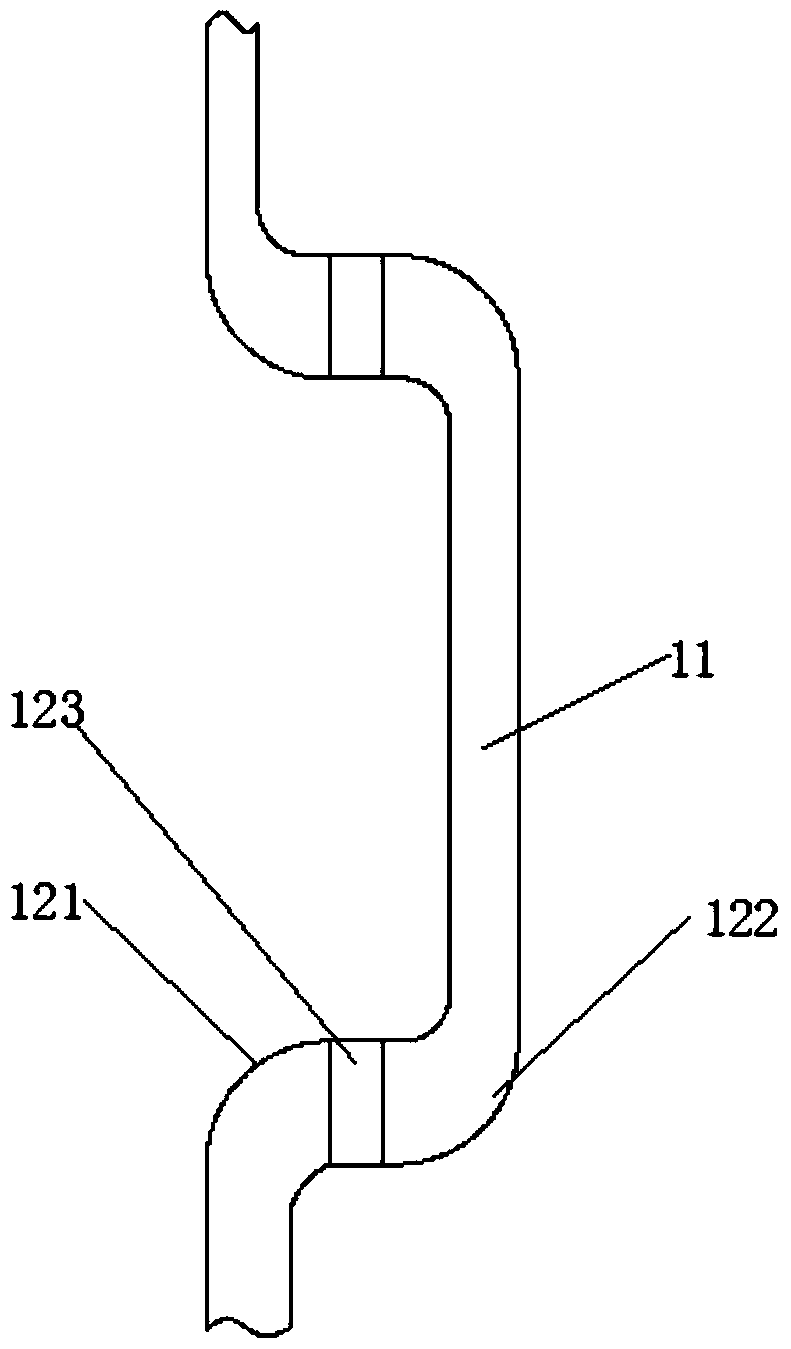

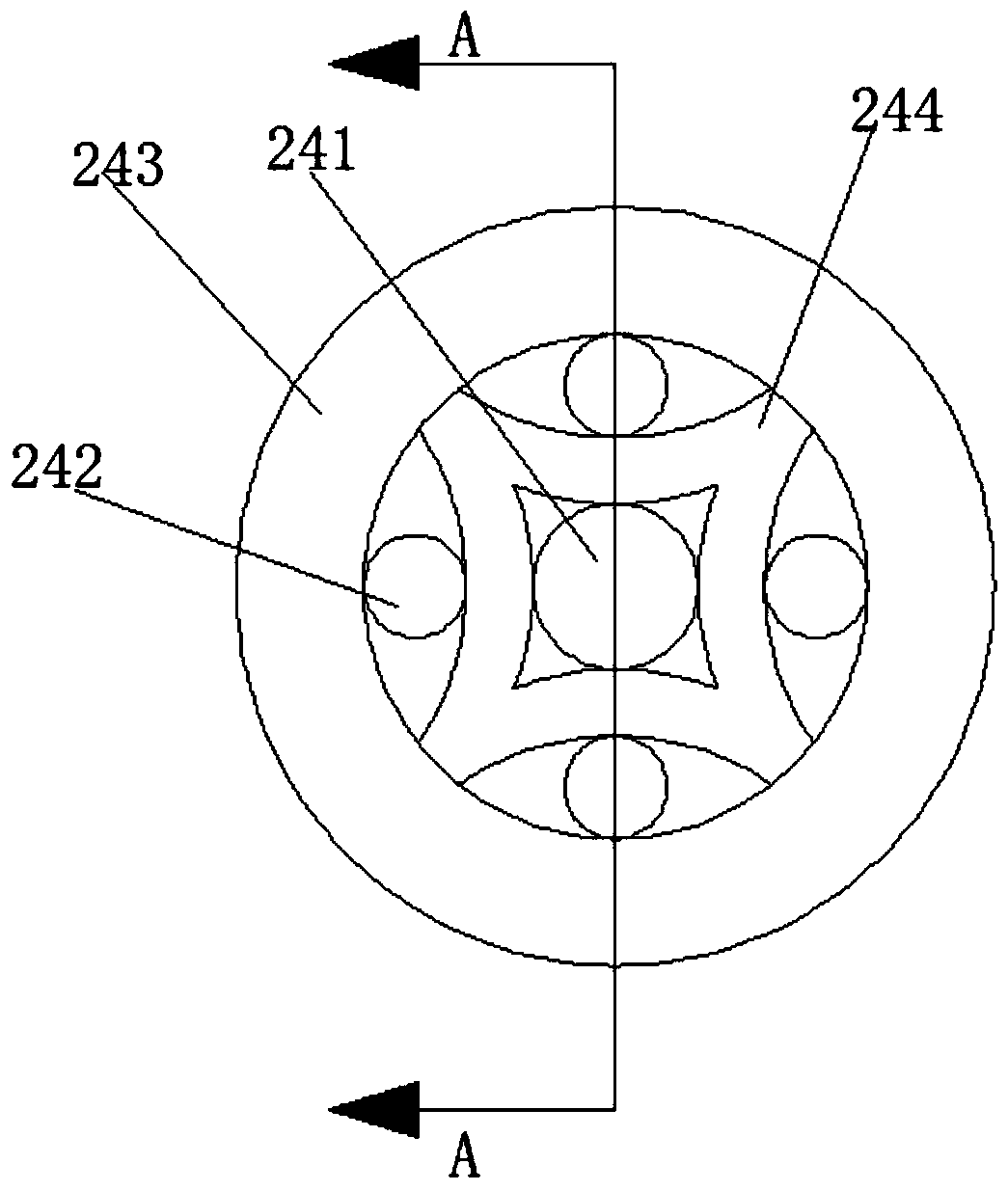

[0018] refer to Figure 1 to Figure 4 A throttling and pressurized conveying device for a fire truck is shown, which includes a foldable feed pipe 1 and a nozzle 2, and the automatically foldable feed pipe includes a plurality of steel pipes 11, a plurality of movable joints 12 and a plurality of hydraulic cylinders 4 , the movable joint 12 includes a left hemispherical surface 121, a right hemispherical surface 122 and a sealed bearing assembly 123, the left hemispherical surface 121 and the right hemispherical surface 122 are flexibly connected by the sealed bearing assembly 123, the left hemispherical surface 121 and the right hemispherical surface 121 The surface 122 can rotate relatively, and the adjacent steel pipes 11 are connected by the movable joint 12, one steel pipe 11 is fixedly connected to the left hemispherical surface 121 of the movable joint 12, and the other steel pipe 11 is fixedly connected to the right side of the movable joint 12 The hemispherical surfac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap