An automatic reel changing robot

A robot and automatic replacement technology, applied in the field of wire drawing machines, can solve problems affecting work capacity, shutdown and maintenance, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

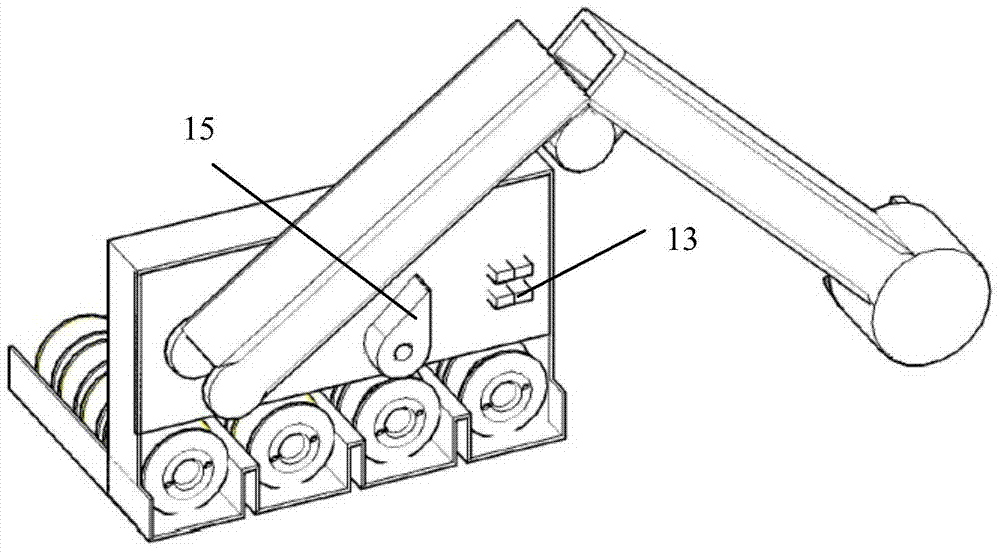

[0032] In the prior art, the coiling equipment of most wire drawing machines is fixed, and the reel changing work is performed manually. There is also an automatic wheel-changing wire take-up machine on the market, which is fixed to a wire drawing machine, and automatically changes the wheel after the reel is full. The automatic wheel change take-up machine adds an automatic wheel change device on the basis of the traditional wire take-up machine, the cost is relatively high, and the use efficiency of the automatic wheel change device is low. Especially the kind of reel that takes more than 2 hours to collect a full reel. This is also one of the reasons why automatic wheel-changing take-up machines are rarely used in factories. And once the wire take-up machine breaks down, it needs to be shut down for maintenance, which will affect the work capacity.

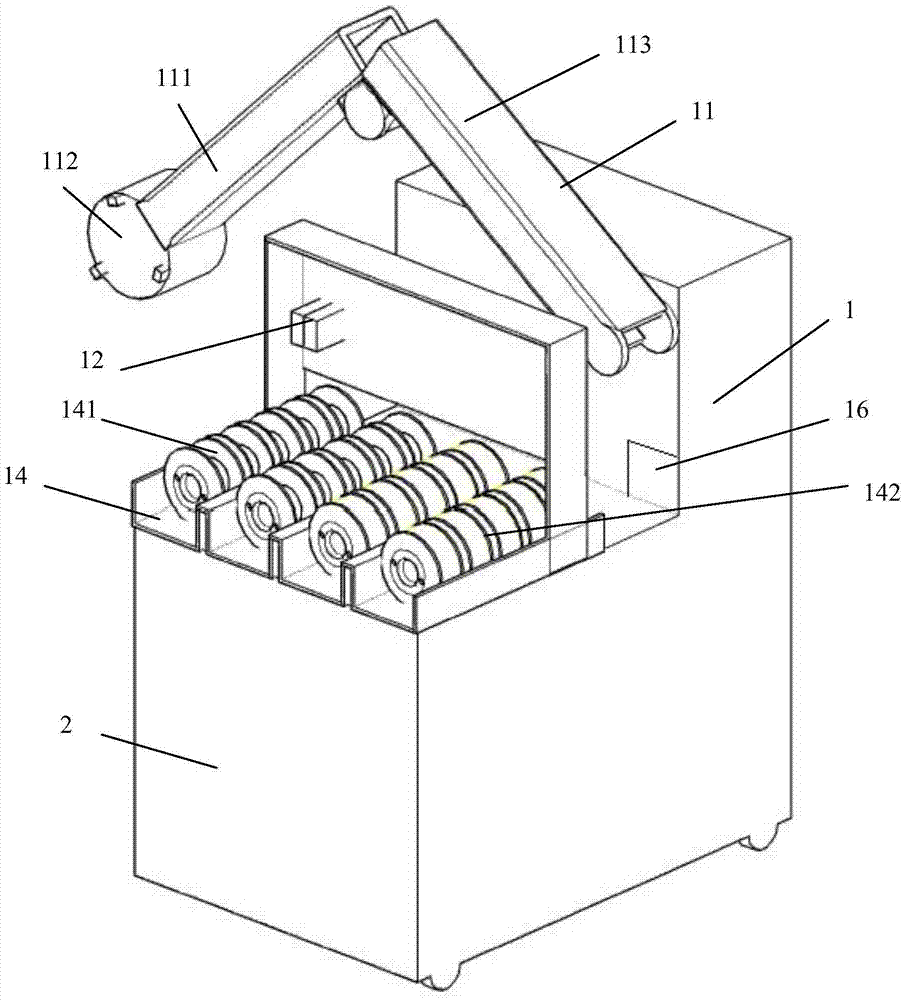

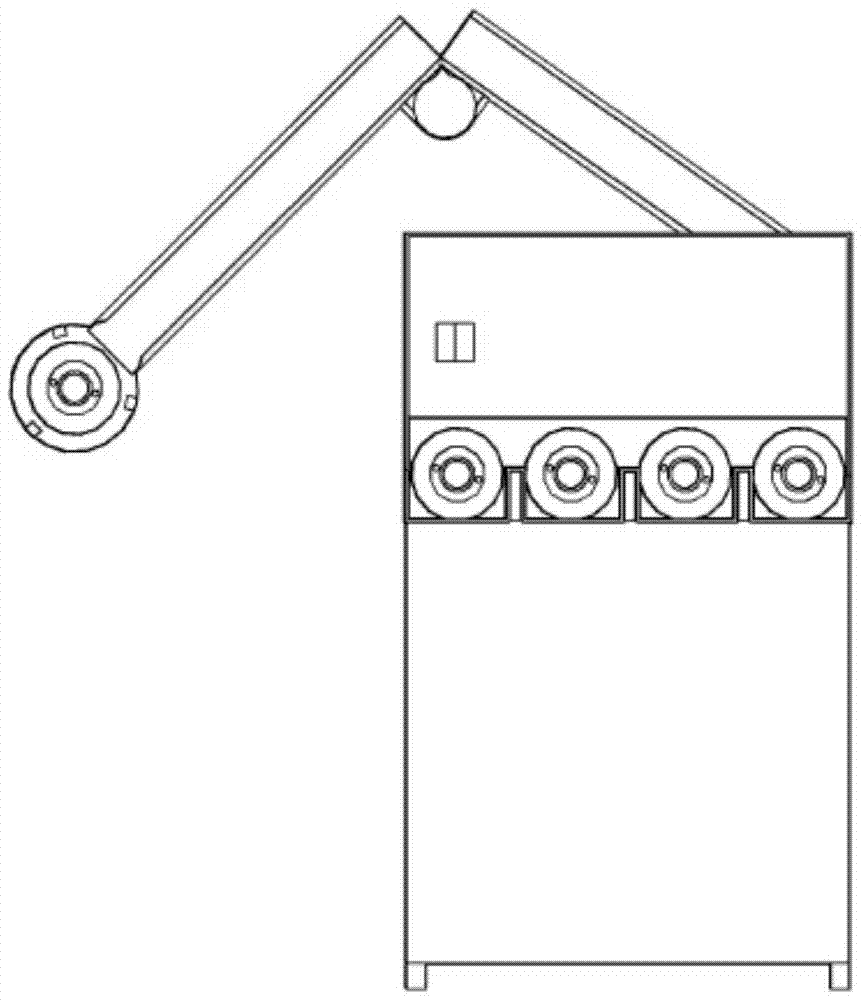

[0033] Aiming at the deficiencies in the prior art, the present invention provides an automatic reel changing robot, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com