Filing recovery device

A recovery device and iron cutting technology, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of cleaning dead corners, complex structures, and difficulty in cleaning broken iron and cutting, so as to save costs and clean up , clean up thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

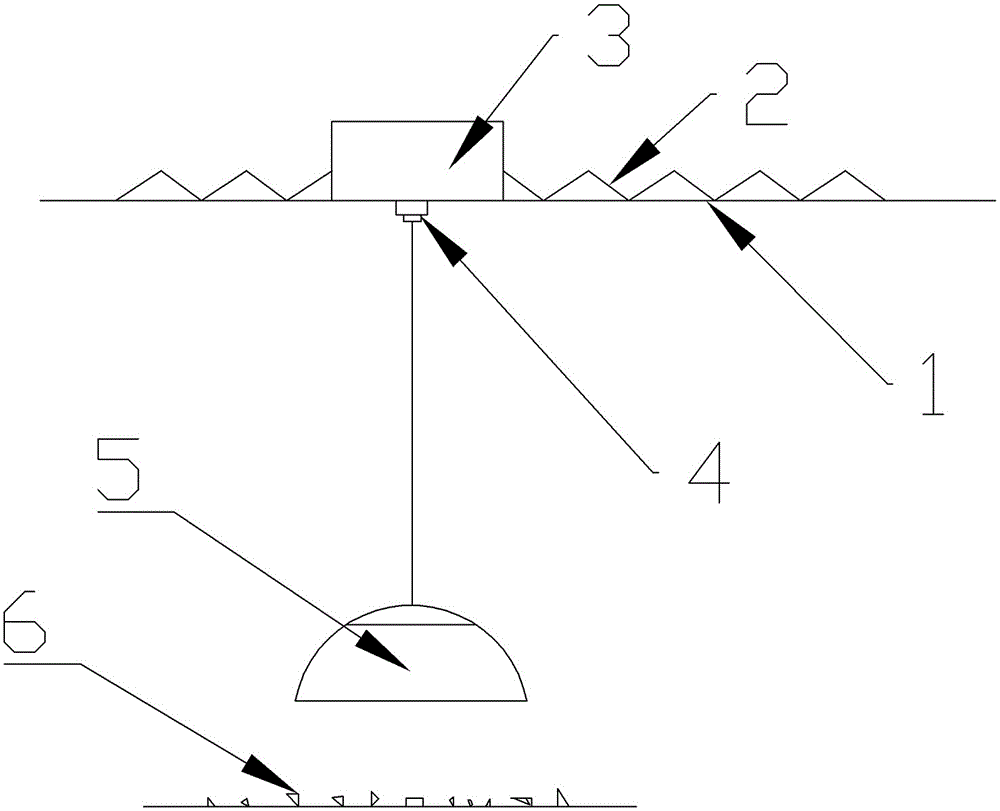

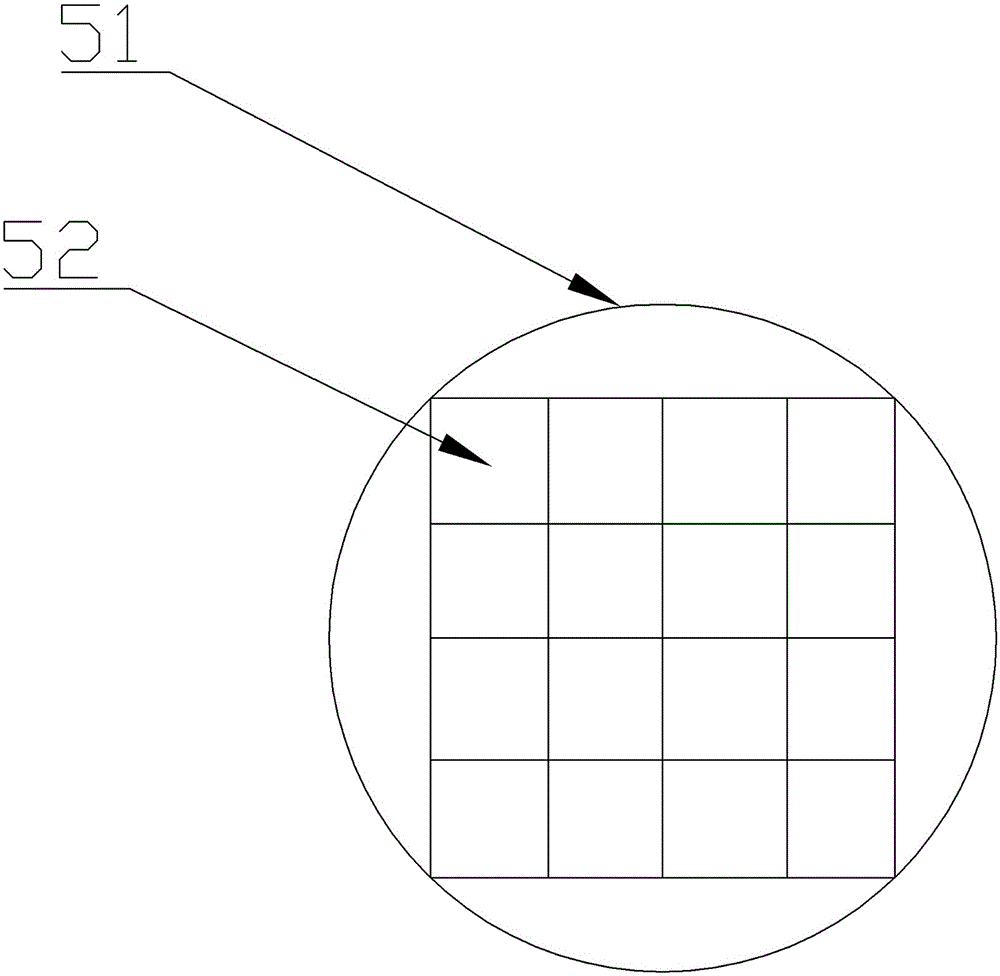

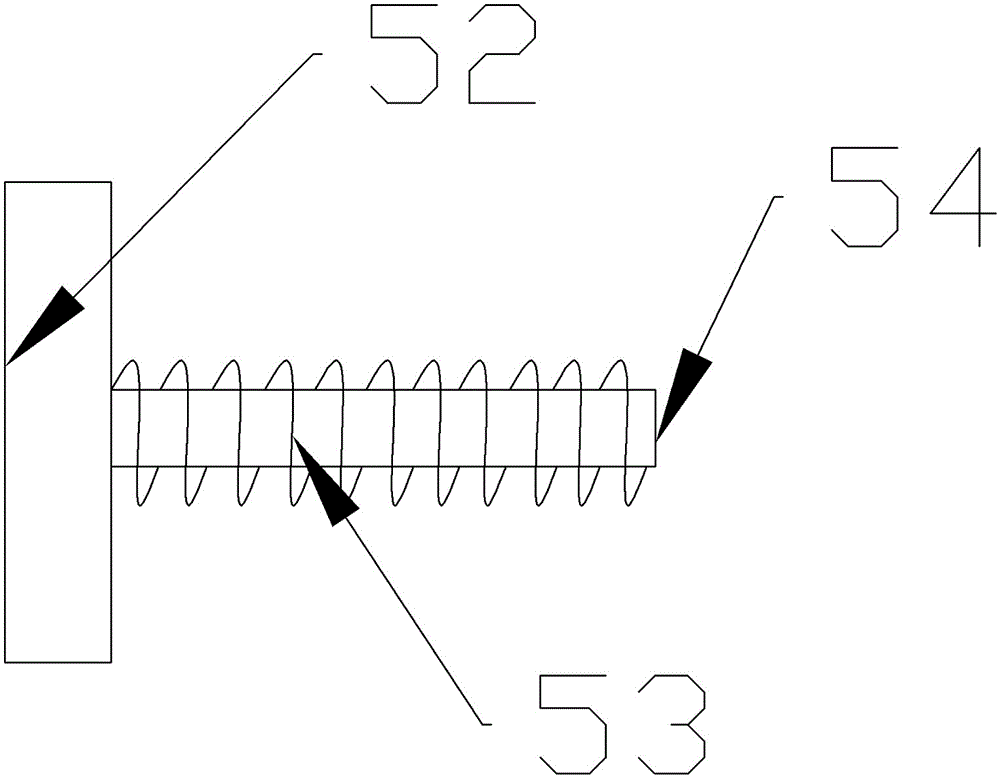

[0015] Such as figure 1 As shown, the iron cutting 6 recovery equipment of the present invention is equipped with two parallel guide rails 1 on the top of the machine tool, and a rack 2 is provided on the guide rail 1; It is connected with the slider 3 through the gear and the rack 2. Noose 4 is installed at the bottom of slide block 3, and noose 4 is wound around stay cord, and the lower end of stay cord is connected with sucker 5. Such as figure 2 , image 3 Shown, sucker 5 comprises the hemispherical sucker cover 51 of opening downwards, and sixteen electromagnets are installed in the sucker cover 51, and electromagnet comprises iron core 54 and sucker sheet 52 that are integrated, and iron core 54 elongates, The sucker sheet 52 is a square shape, the sucker sheet 52 is positioned at the bottom end of the iron core 54 and is perpendicular to the iron core 54, the coil 53 is wound on the iron core 54, and the side lengths of each sucker sheet 52 are bonded together to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com