a grabbing device

A grasping device and gripper technology, applied in the field of grasping devices, can solve the problems of broken hooks, heavy weight, and inability to achieve the degree of intelligence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

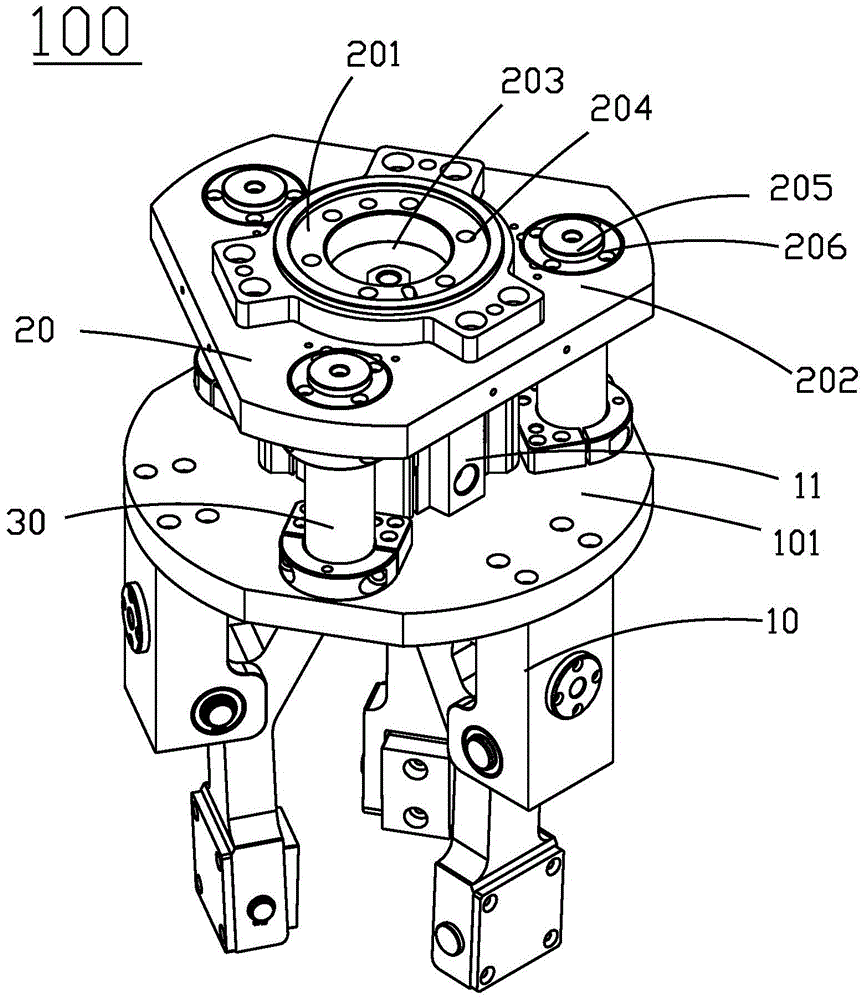

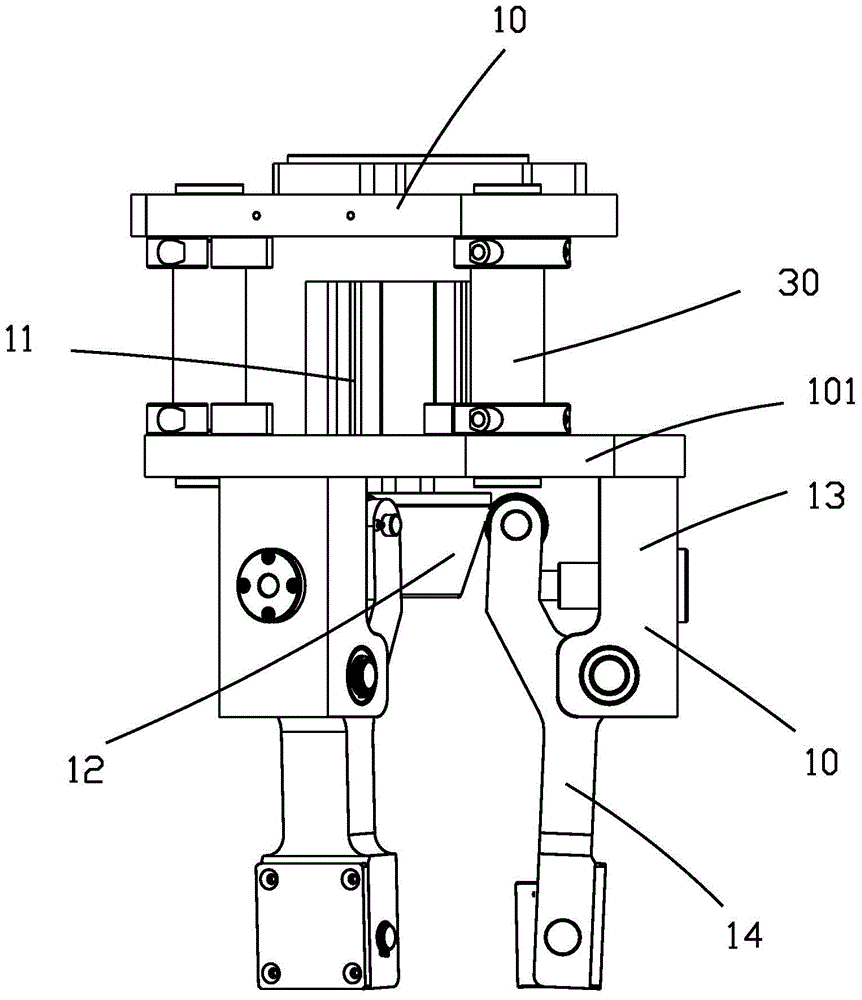

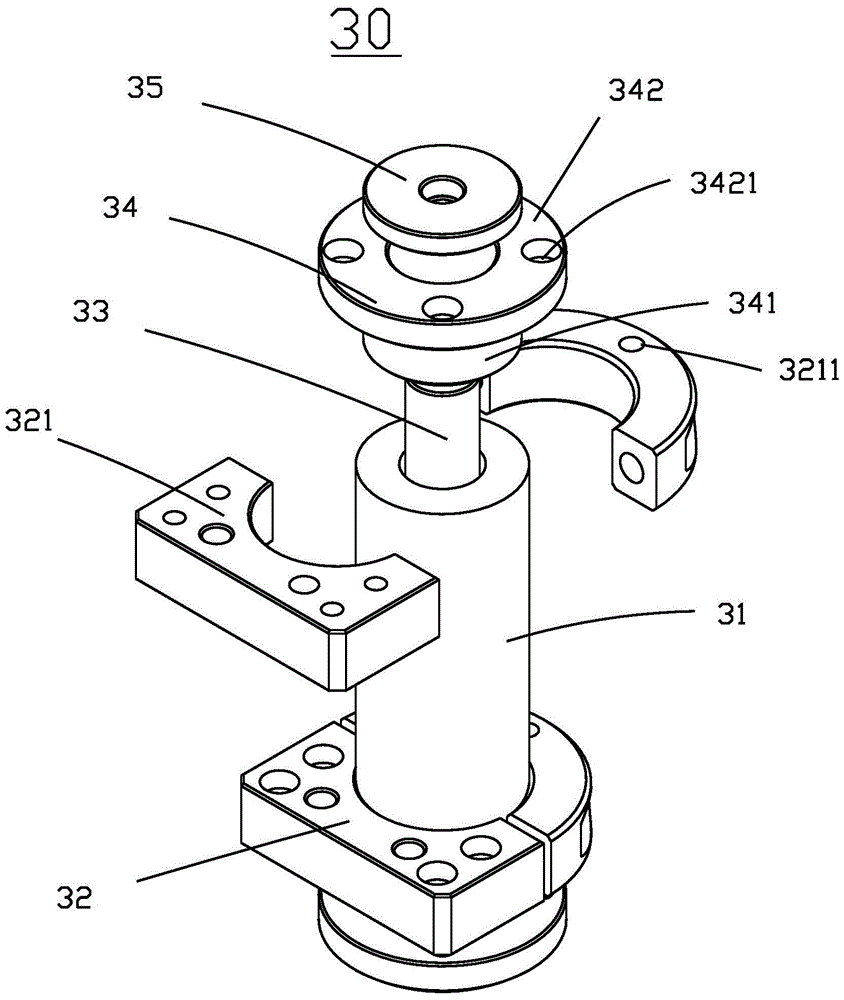

[0024] see Figure 1 to Figure 9 As shown, the present invention discloses a grasping device 100 , which includes a connecting component 20 , a jaw component 10 and a floating component 30 located between the connecting component 20 and the clamping jaw component 10 .

[0025] Such as figure 1 , figure 2 As shown, the connecting assembly 20 includes a connecting plate 201 for connecting with a moving arm (not shown) and a fixing plate 202 for installing the connecting plate 201 . The connecting plate 201 and the fixed plate 202 are installed in parallel with each other, the center of the fixed plate 202 and the connecting plate 201 is provided with a central hole 203 for installing the mobile arm, and a number of fixed holes 204 are arranged around the central hole 203 of the connecting plate 201. Used to assist in immobilizing the moving arm. A plurality of mounting holes 205 are defined around the fixing plate 202 . The installation hole 205 is used for the floating ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com