Test paper automatic assembly and binding device

An automatic assembly and test paper technology, applied in binding, printing, etc., can solve labor-intensive problems and achieve the effects of reduced extraction time, low cost, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

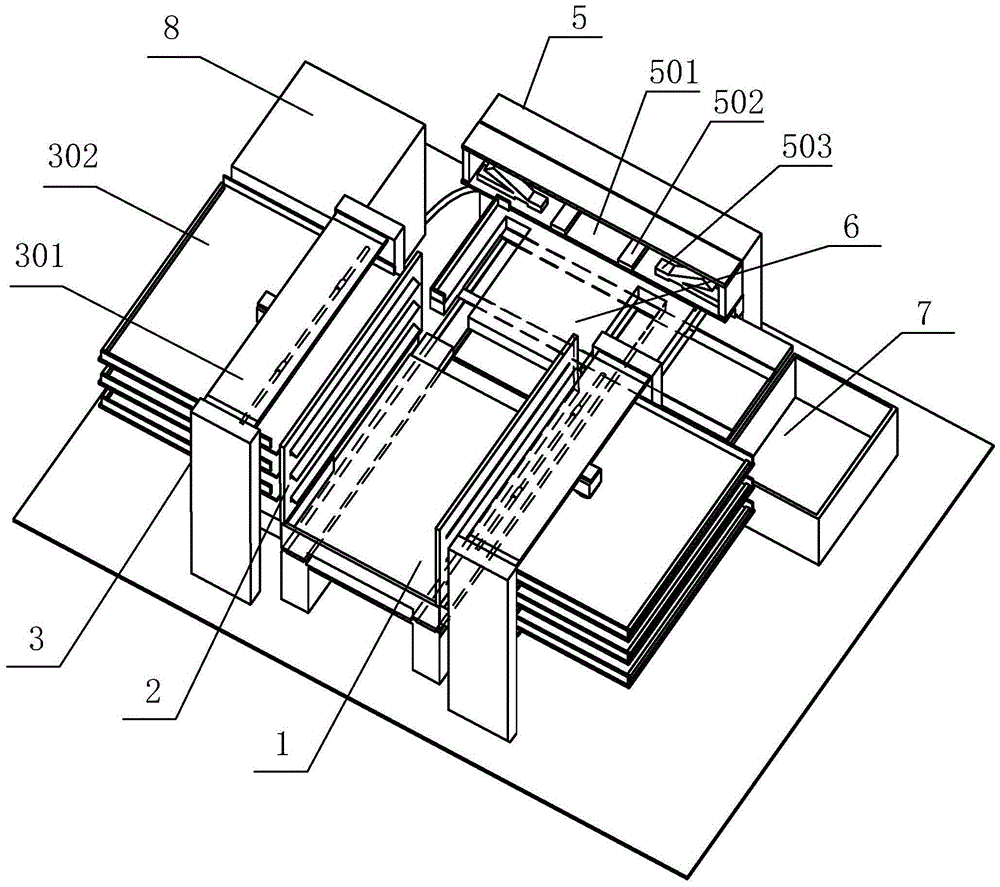

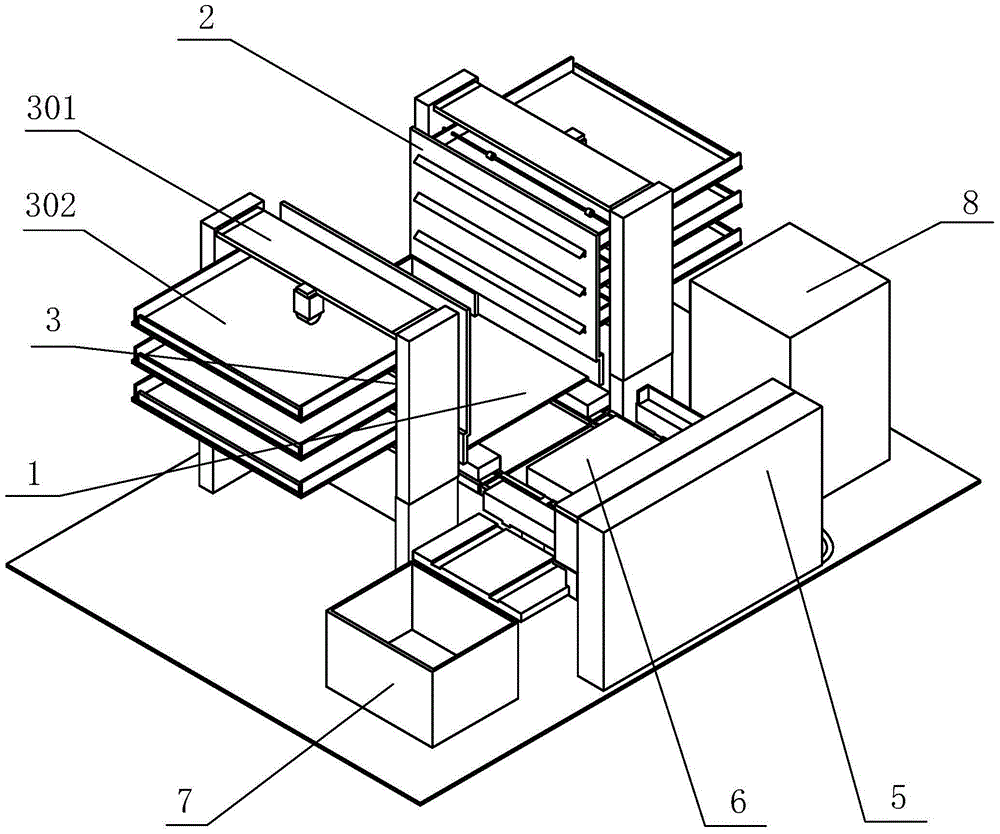

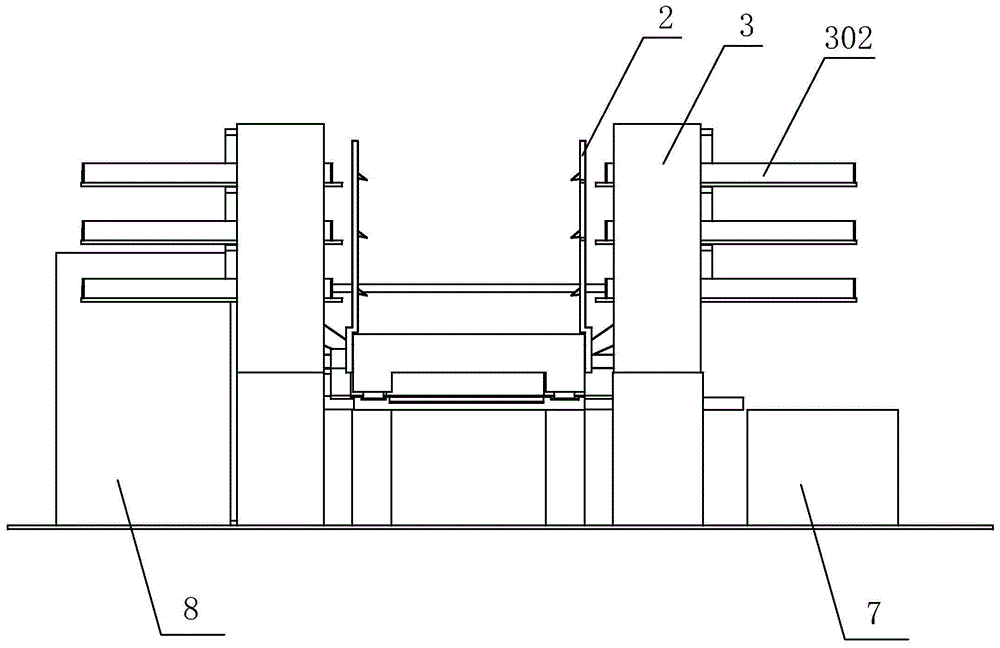

[0047] A test paper automatic assembly and binding device, comprising a test paper assembly receiving box 1, two slotted baffles 2 placed relatively parallel, a test paper extraction mechanism 3, a test paper delivery mechanism 4, a test paper binding mechanism 5, a test paper binding receiving box 6, Test paper receiving box 7, control system 8; where:

[0048] Between the two slotted baffles 2, the test paper assembly receiving box 1 is arranged longitudinally; The rear end is the described test paper binding receiving box 6 arranged horizontally, and the rear side of the test paper binding receiving box 6 is provided with the described test paper binding mechanism 5; the described test paper assembly receiving box 1 and the test paper binding receiving box 6 bottom are The test paper conveying mechanism 4, the test paper assembly receiving box 1, the test paper binding receiving box 6 respectively roll and cooperate with the test paper conveying mechanism 4; the described c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com