Universal horizontal elastic combined support

A technology of horizontal elastic and two-way sliding bearings, which is applied in the direction of building components, earthquake resistance, construction, etc., can solve the problems of loss of limited spring stiffness, spring stuck, limited sliding function, etc., achieve simple structure, eliminate possible stuck, Clear force transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

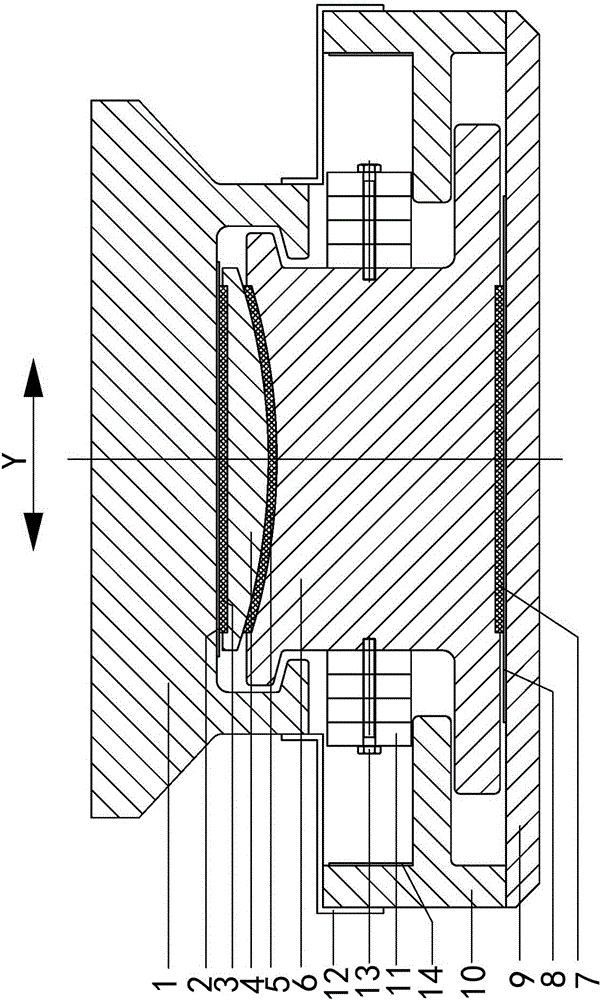

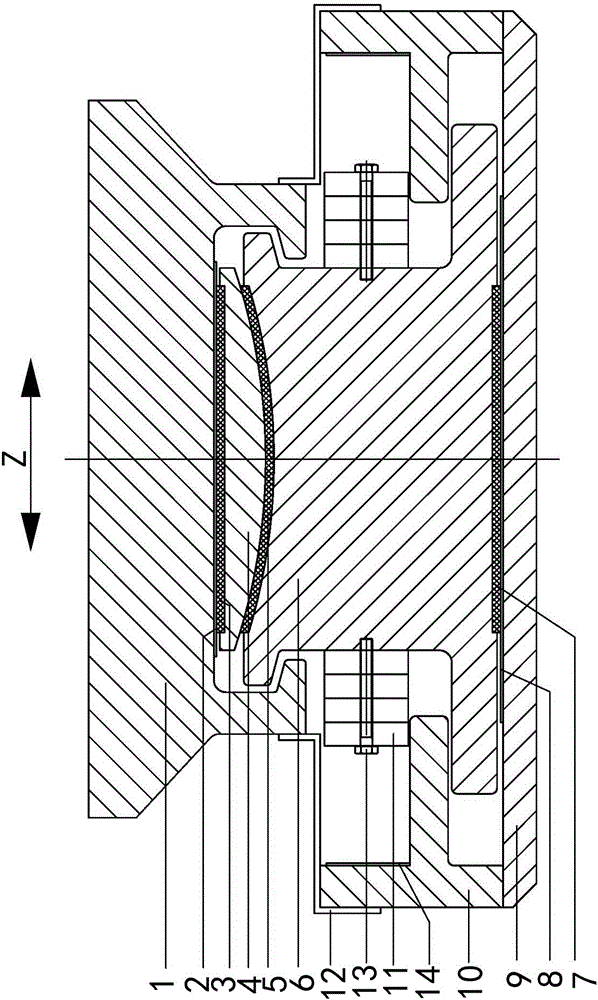

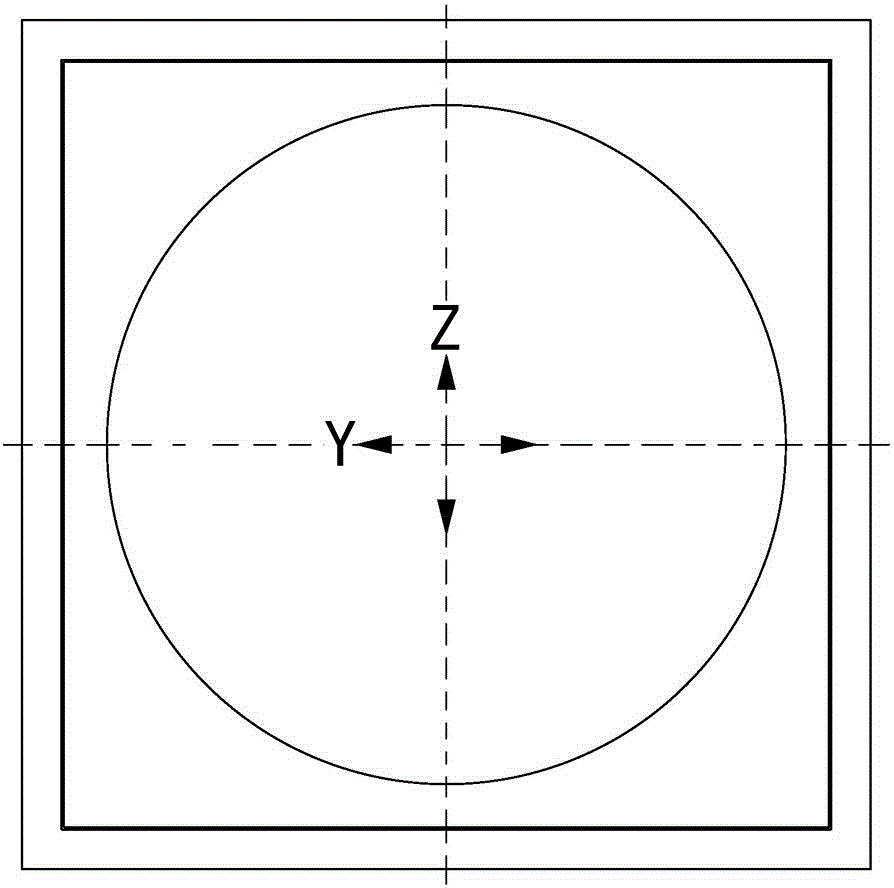

[0030] Examples see Figure 4-5 As shown, a universal horizontal elastic composite support includes at least one bidirectional sliding support 23 and at least one universal horizontal elastic support that are connected between the upper structure 15 and the lower structure 16 and arranged side by side.

[0031] see Figure 6 As mentioned, the two-way sliding support 23 includes a sliding support connecting rod 24 sequentially connected from top to bottom, an upper support plate 25 of the sliding support, a stainless steel plate 26 of the sliding support, a polytetrafluoroethylene plane slide plate of the sliding support 27. The middle body 28 of the sliding support, the polytetrafluoroethylene spherical slide plate 29 of the sliding support and the lower bearing plate 30 of the sliding support.

[0032] see Figure 7-11 As shown, the universal horizontal elastic support is composed of the upper support plate 1 connected with the upper structure 15, the lower support plate 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com