Cross cementing method without occupying the wellhead

A technology for cementing and surface casing, which is used in wellbore/well components, earth-moving drilling, sealing/packing, etc. The effect of casing hanging on the wall, improving aging and realizing wellbore integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

[0020] The cross cementing method without occupying the wellhead of the present invention comprises the following steps:

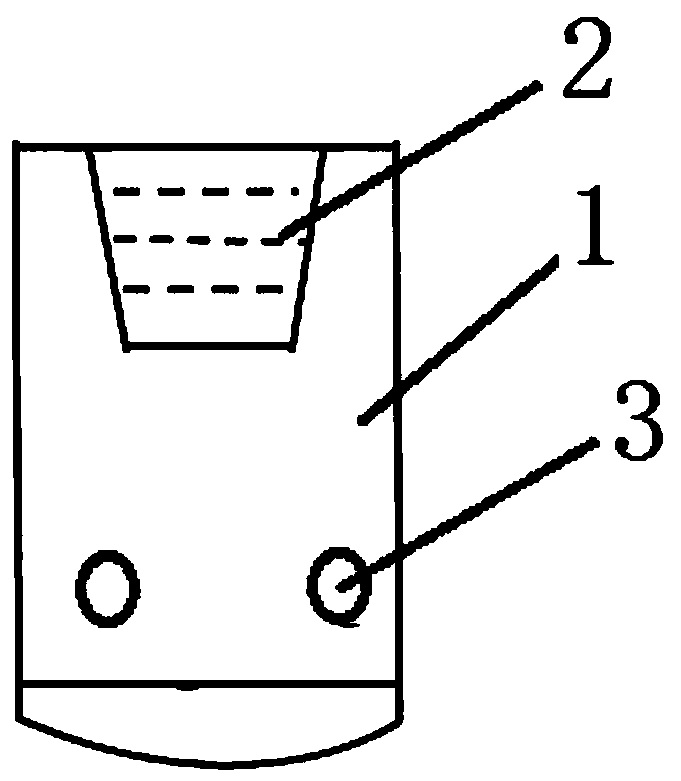

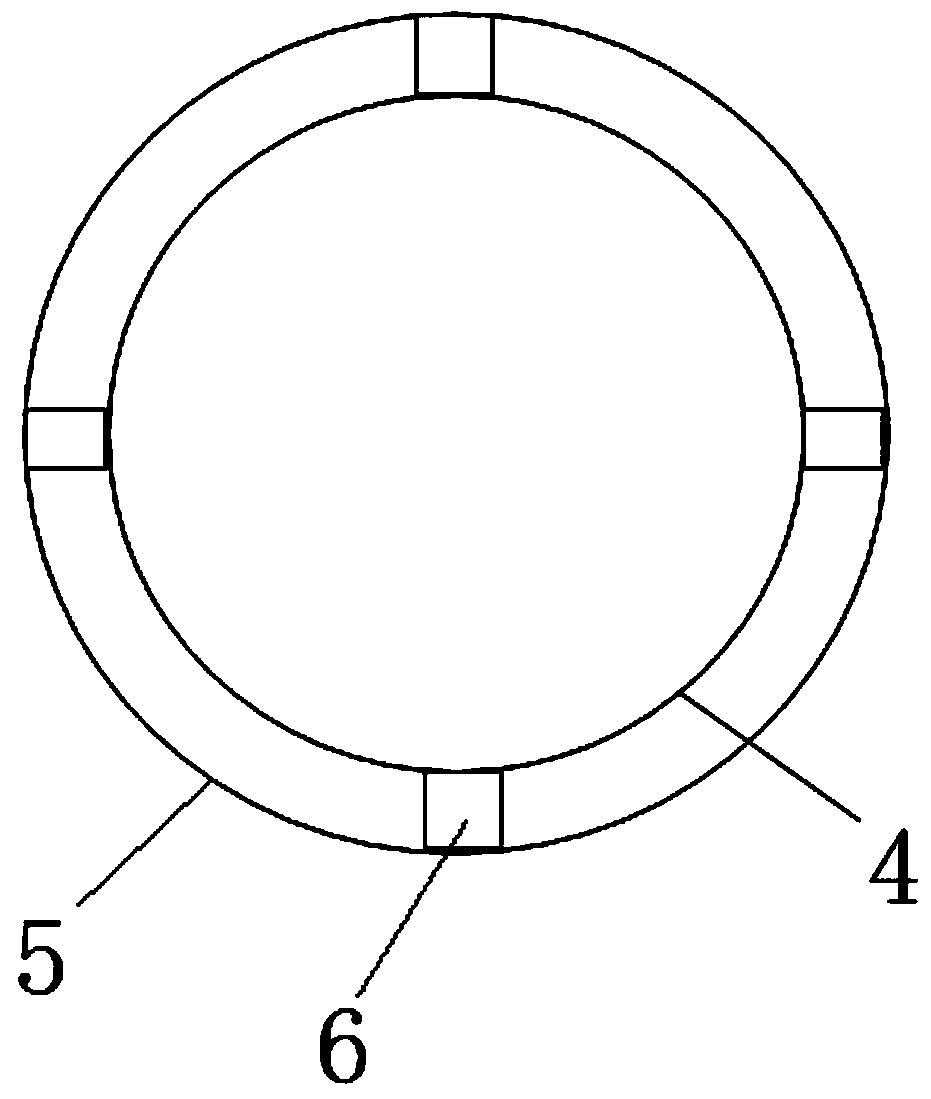

[0021] S1. Connect the casing floating shoe 1 at the lower end of the 20″ surface casing 4. The structure of the casing floating shoe is as follows figure 1 As shown, the casing float shoe 1 is provided with a plurality of evenly distributed side outlet holes 3 on the side wall below the float shoe check valve seat 2, and by setting the side outlet holes 3 on the side wall of the casing float shoe 1 , the flow channel formed by the side outlet hole can be used to ensure the cementing operation, and the casing float shoe plays the dua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com