Gear box elastic support component of wind turbine generator set

A wind turbine, elastic support technology, applied in wind turbine components, wind turbines, engines, etc., can solve the problems of high production cost and inspection cost, heavy weight, and large volume of elastic support components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

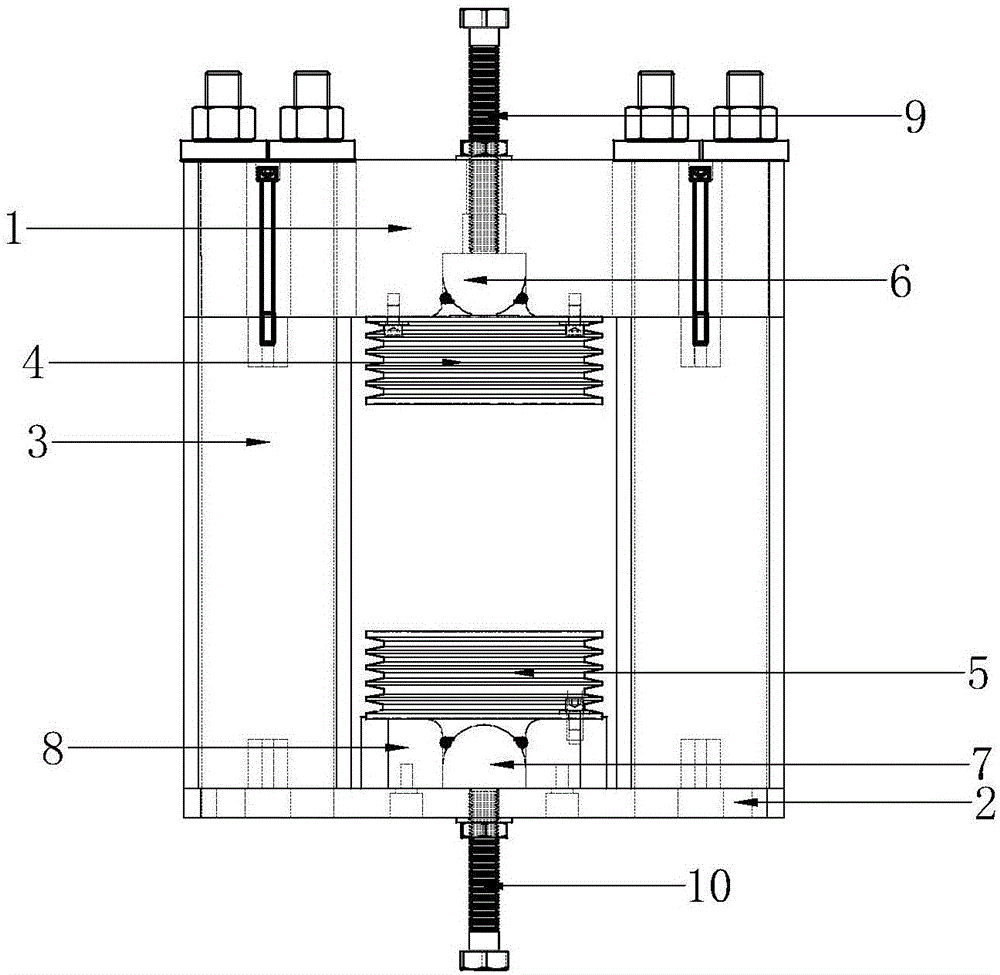

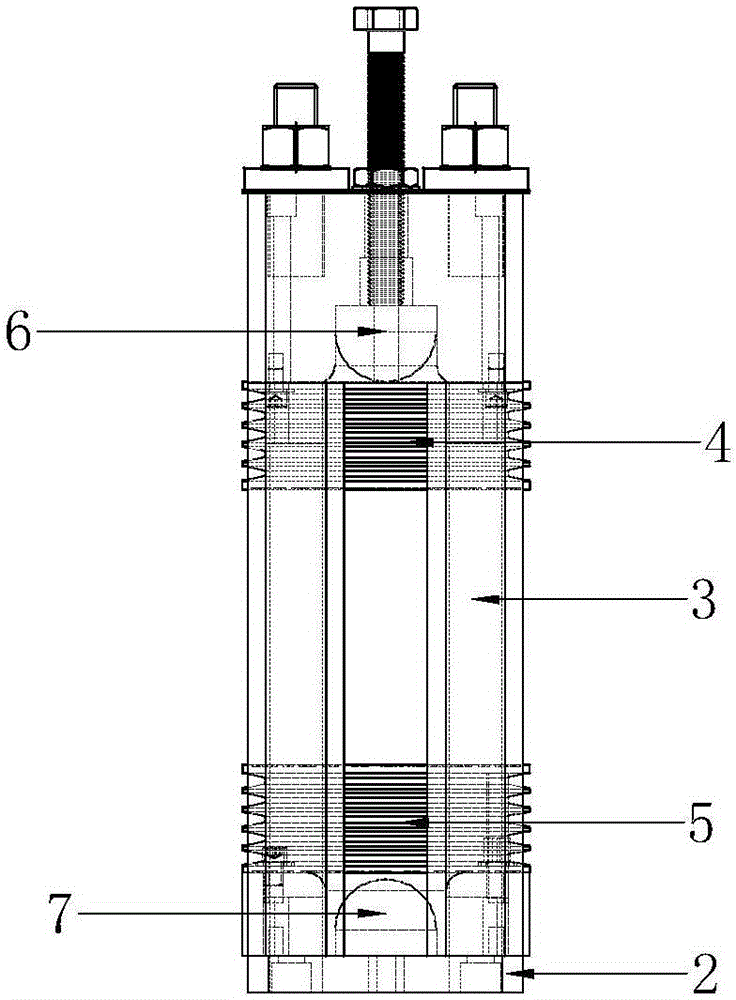

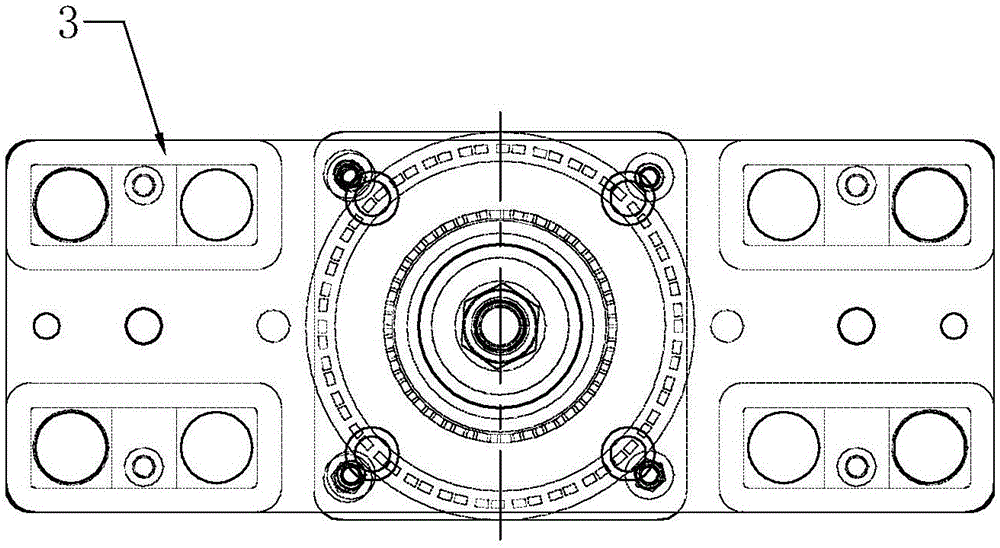

[0021] Such as figure 1 , figure 2 , Figure 4 As shown, the elastic support assembly of the gearbox of the wind turbine generator of the present invention includes an upper base 1 and a bottom plate 2 and two uprights 3 connected between the upper base 1 and the bottom plate 2, such as Figure 4 As shown, the cross-sectional shapes of the outer contours of the two uprights 3 are both rectangular, and at the same time, the two uprights 3 can be set as hollow uprights. At this time, two partitions can be arranged in the two uprights, thereby making the entire upright The cross section is formed into a substantially mesh-shaped structure. When installed, the two uprights 3 are respectively located at the edge of the left and right sides of the upper base 1, and the two uprights respectively penetrate the entire width direction of the side. Through this structural design, The upper seat body 1, the bottom plate 2 and the two uprights 3 constitute a frame structure. The bottom cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com