Method for inspecting contact between mating gears

A technology of pairing gears and gears, applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission, etc., can solve the problems of difficult to remove, dirty gear meshing paint, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

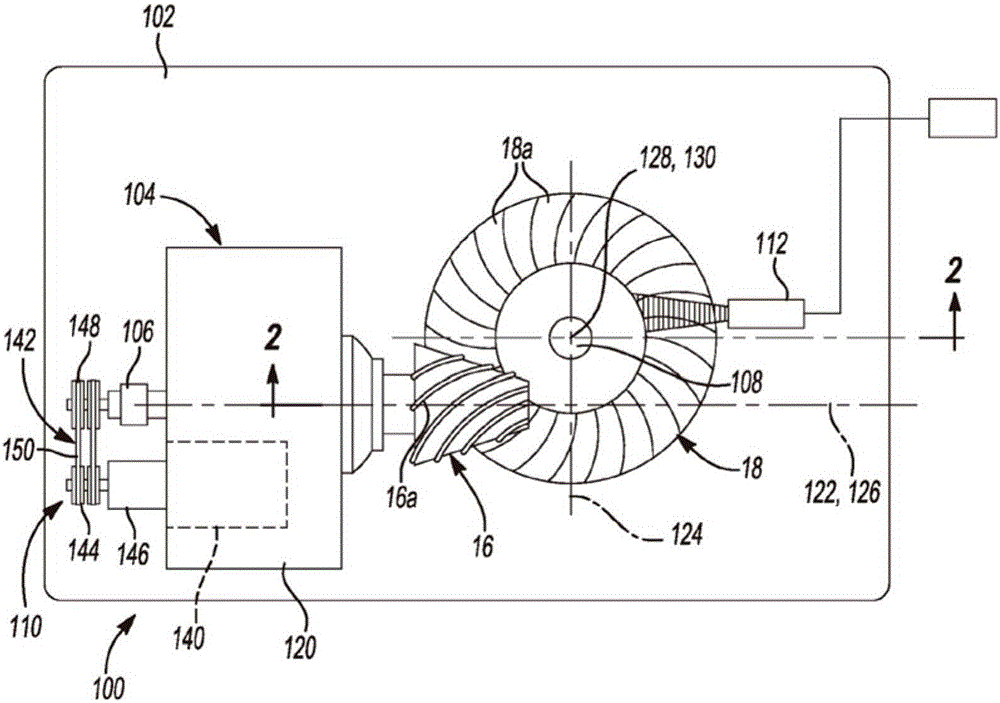

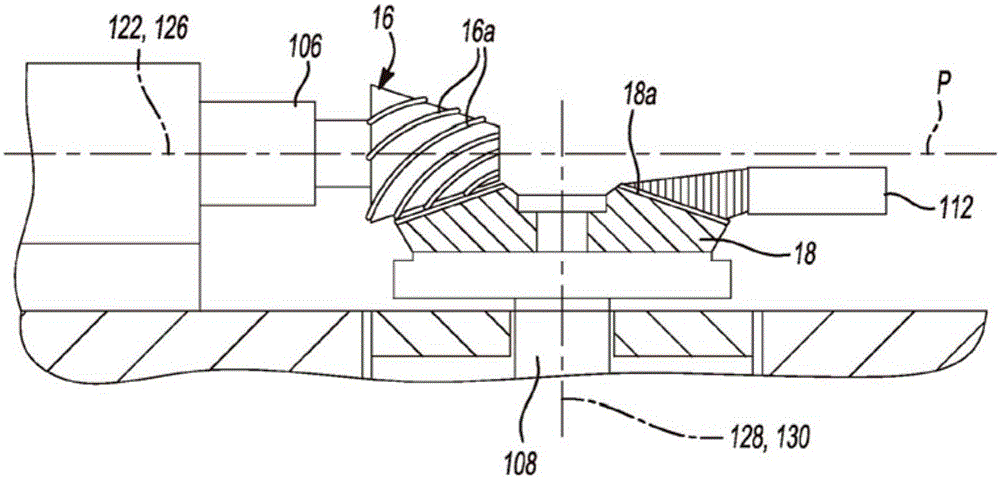

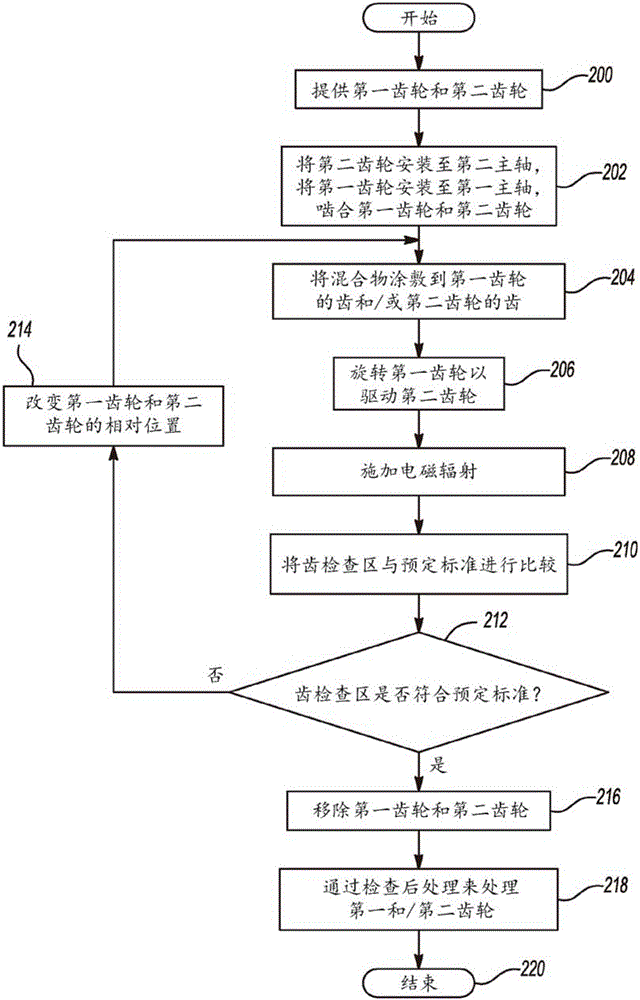

[0018] see figure 1 and figure 2 , an exemplary gear inspection apparatus for performing a method for inspecting contact between mating gears according to the teachings of the present disclosure is generally indicated by reference numeral 100 . The gear inspection device 100 may be configured to facilitate collecting, collecting and / or analyzing data related to the quality of mesh between the teeth 16 a of the first gear 16 and the teeth 18 a of the second gear 18 . In the particular example provided, the first gear 16 is a hypoid spiral bevel pinion and the second gear 18 is a hypoid spiral bevel ring gear. However, it will be appreciated that the teachings of the present disclosure are applicable to other gear types, such as helical and spur gears.

[0019] The gear inspection apparatus 100 may include a base 102 , a carriage mechanism 104 , a first spindle 106 , a second spindle 108 , a rotational power source 110 and an electromagnetic radiation source 112 . The carria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com