Pneumatic type high branch fruit thinning scissors

A pneumatic, high-branch technology, applied in cutting tools, cutting equipment, gardening, etc., can solve the problems of high labor intensity, low operation efficiency, weak pruning force, etc., and achieves compact and firm overall structure, light overall structure, and pruning. quick action effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

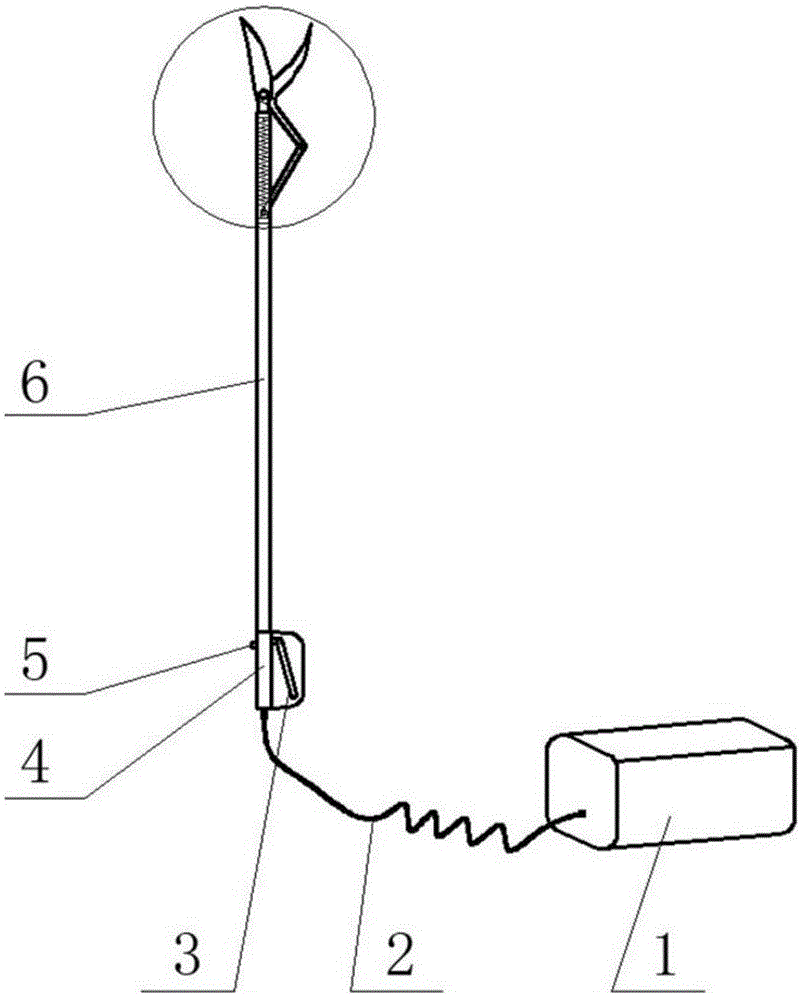

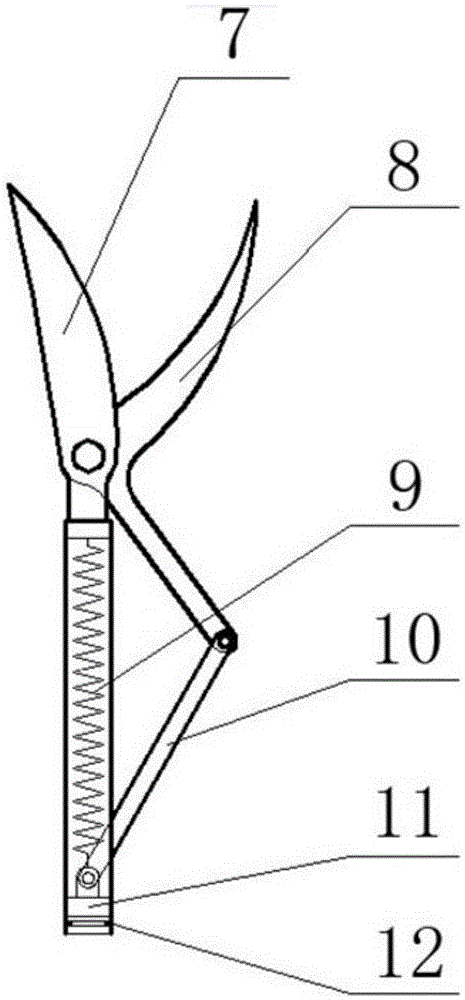

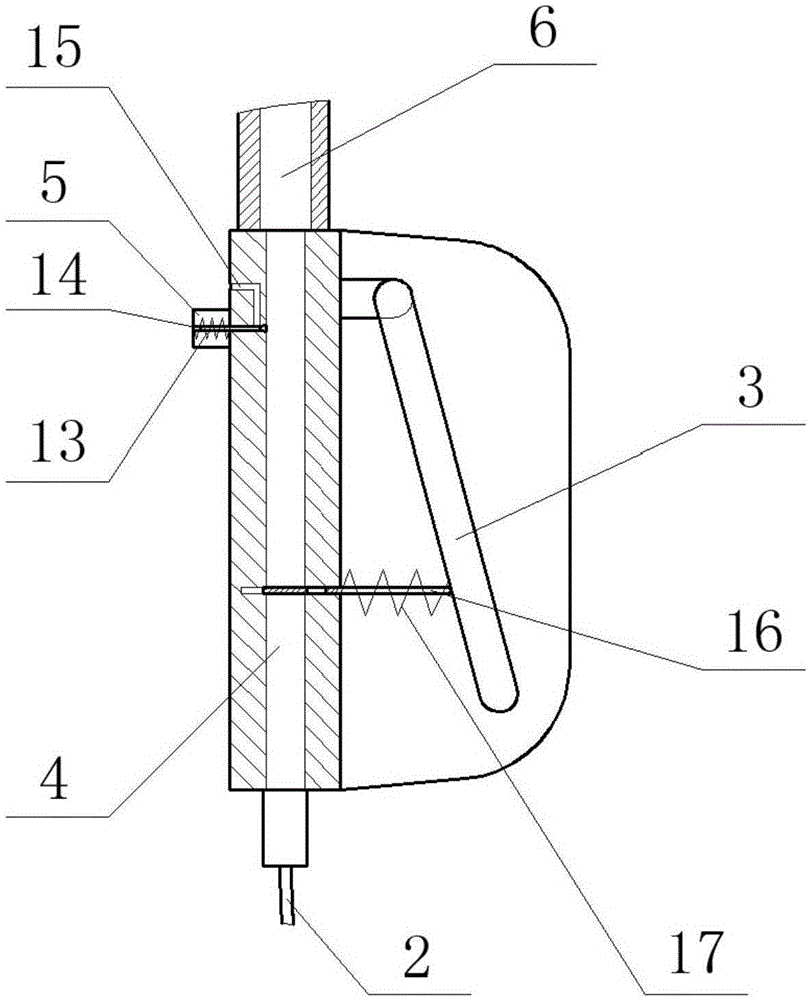

[0015] Such as figure 1 image 3 A kind of pneumatic high-branch fruit thinning shears shown includes a scissors part. The scissors part includes a fixed knife arm 7 and a movable knife arm 8 hinged thereto. The connecting end of the fixed knife arm 7 is connected to a hollow tube 6, and the hollow tube 6 The other end is connected to the air source, and the end of the hollow tube 6 connected to the air source is covered with a handle 4. The air source includes the air pump 1 and the air tube 2 connecting the air pump 1 and the hollow tube 6. Air intake mechanism and exhaust mechanism are housed on the hollow pipe 6, and the intake mechanism and exhaust mechanism can be arranged on the handle 4. The intake mechanism includes an intake switch 3, one end of the intake switch 3 is hinged to the outer wall of the handle 4, the middle part of the intake switch 3 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com