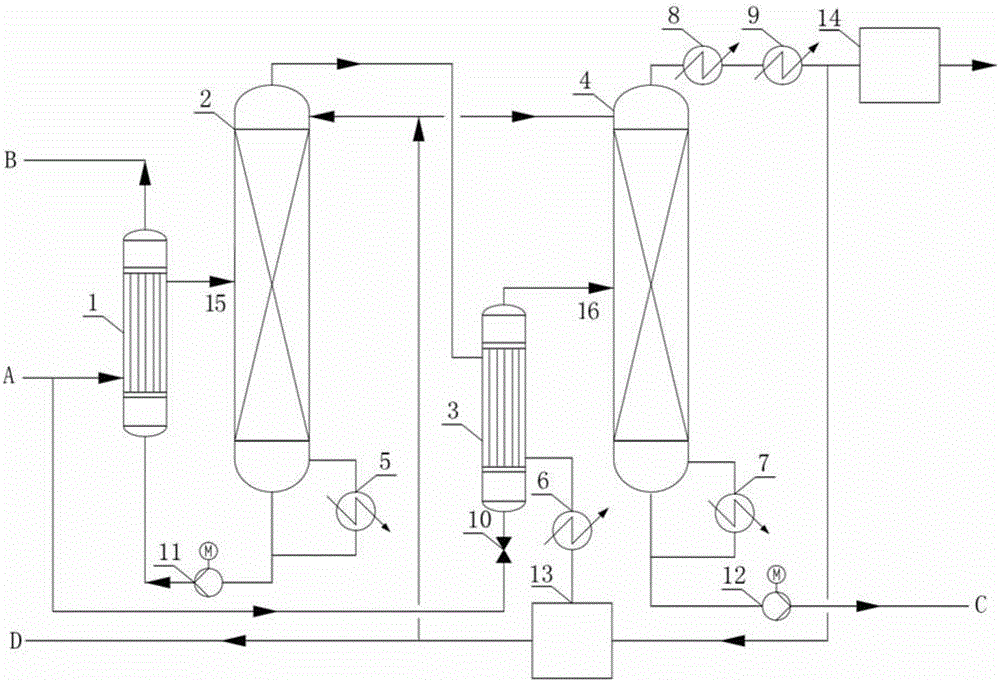

tert-butanol-water-cyclohexanone oxime differential-pressure rectification system

A technology of cyclohexanone oxime and differential pressure rectification, which is applied in the field of tert-butanol-water-cyclohexanone oxime differential pressure rectification system, can solve problems such as energy mismatch, achieve energy saving and realize full energy The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take the treatment of 100 tons of tert-butanol-water-cyclohexanone oxime raw material solution per hour as an example for description.

[0028] A kind of tert-butanol-water-cyclohexanone oxime differential pressure rectification system, such as figure 1 As shown, the pressure of the tert-butanol-water-cyclohexanone oxime raw material liquid A from the reaction tank area is 4MPaA, and the temperature is 85°C. According to the split ratio of high-pressure tower: low-pressure tower: 1:1.25, it is divided into two streams, and one stream passes through the first A preheater 1 is preheated and sent to the high-pressure tower feed port 15 of the high-pressure tower 2. After preheating, the temperature is 93° C., the operating pressure of the high-pressure tower is 0.17 MPaA, the temperature at the top of the tower is 92° C., and the temperature of the tower kettle is 120°C, the first tower reboiler 5 (one-pass reboiler) is heated by low-pressure steam, and the high-pressure t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap