Gear box mold for locomotive driving device

A driving device and gearbox technology, applied in the field of gearbox molds, can solve the problems of thermal deformation of the mold, shorten the service life of the mold, and low yield of the gearbox, and achieve the effects of preventing thermal deformation, increasing the service life, and improving the yield of the finished product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

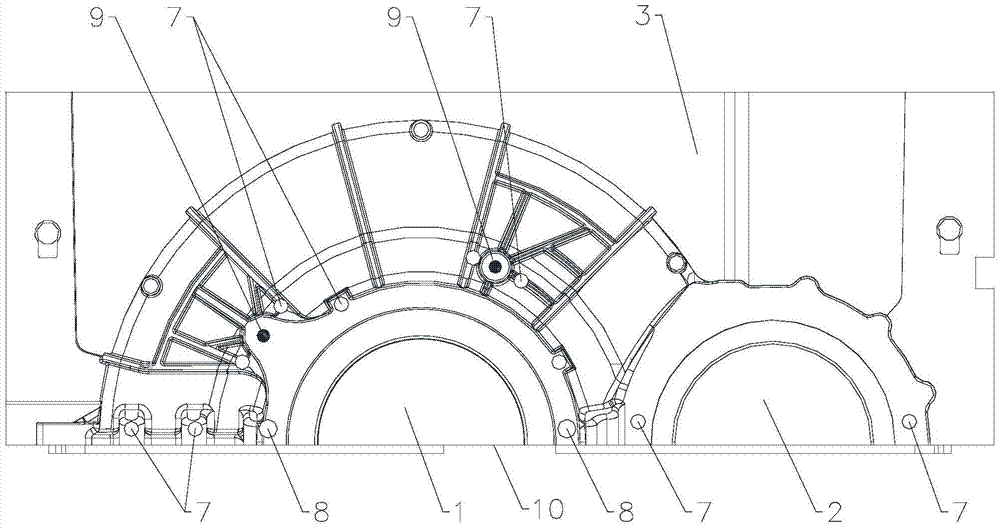

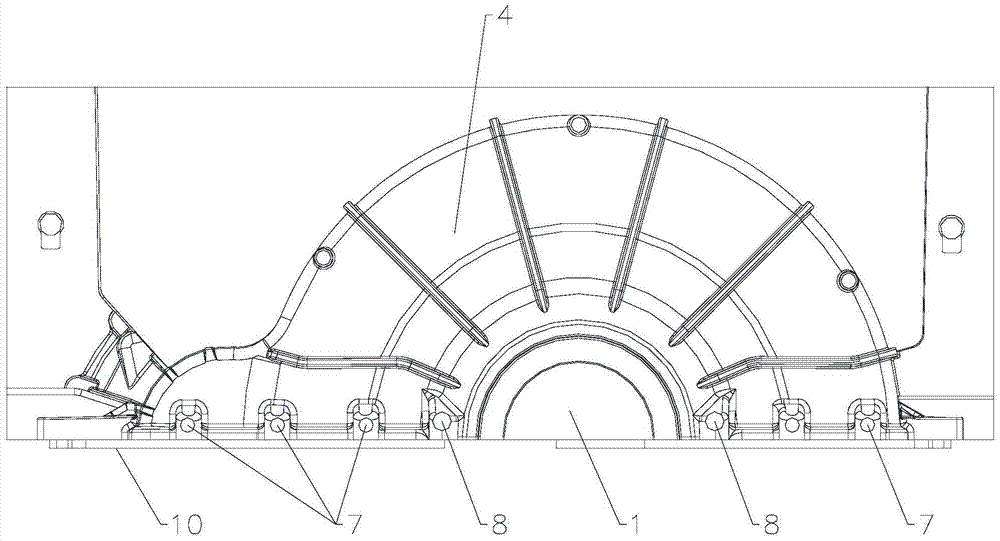

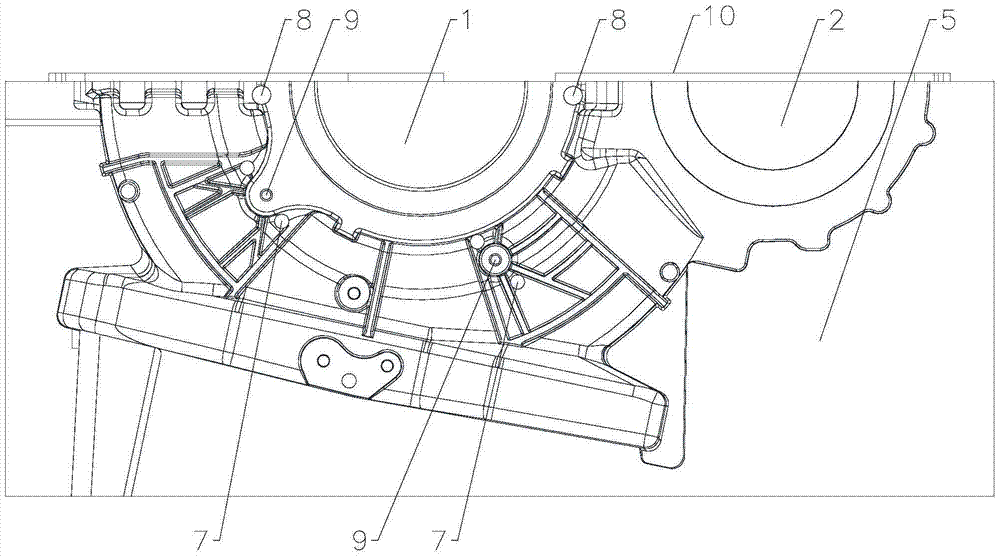

[0019] Such as figure 1 , figure 2 , image 3 and Figure 4 Shown, a kind of gearbox mold for locomotive driving device, comprises formwork shell and mold core, is provided with the first axle hole 1 and the second axle hole 2 on the formwork shell, and formwork shell is made up of front upper side mold 3, rear upper side mold 4. The front lower side mold 5 and the rear lower side mold 6 are composed of the front upper side mold 3, the rear upper side mold 4, the front lower side mold 5 and the rear lower side mold 6 respectively. The front upper side mold 3, The rear upper side mold 4, the front lower side mold 5 and the rear lower side mold 6 are respectively provided with independent cooling ports for cooling the mould. The cooling ports include a cold air port 7 and a cold water port 8. The front lower side mold 5 is respectively provided with a contact surface 10 for connecting the front upper side mold 3 and the front lower side mold 5; the front upper side mold 3 is...

Embodiment 2

[0021] It is basically the same as Embodiment 1, the difference is that: the front upper side mold 3, the rear upper side mold 4, the front lower side mold 5 and the rear lower side mold 6 are respectively provided with cooling fins for increasing the heat dissipation area

[0022] When processing the gearbox, the front upper side mold 3, the rear upper side mold 4, the front lower side mold 5, the rear lower side mold 6 and the mold core are combined to form a gearbox mold, and molten metal is added to the mold through the gate 9 , Install a cold water pipe at the cold water port 8 to cool the mold, and install a cold air pipe at the cold air port 7 to cool the mold. By setting the cold air port 7 and the cold water port 8, the hot joints of the gearbox are cooled to ensure that the box is free of Casting defects improve the yield of the gearbox and greatly increase the service life of the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com