Quick collector for borings

A collector and debris technology, applied in chemical instruments and methods, dust removal, metal processing machinery parts, etc., can solve problems affecting flight safety, cleaning omissions, and inability to clean up, so as to avoid a large number of splashes, improve safety, The effect of facilitating drilling operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

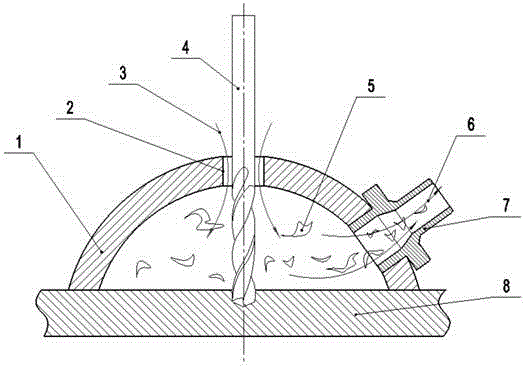

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

[0013] see figure 1 , The main structure of the rapid collector of drilling debris in the present invention is a hemispherical shell 1, which is used to collect debris 5 in the collector. There is a central hole 2 in the center of the hemisphere, which is a drill bit passing through the hole, and the aperture is greater than the drill bit diameter, which is convenient for the drill bit to go in and out. One side of the bottom of the hemispherical shell is another hole with a larger diameter—the debris collection port, which is externally connected to a negative pressure absorption device, and the low-pressure airflow 6 is used to suck away the drilling debris. The shell of the collector is made of transparent engineering plastics, which has good light transmission, and the accumulation of debris in the collection area can be seen clearly; the strength is high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com