Cargo compartment structure capable of intelligently loading and unloading cargos

A cargo box and cargo technology, applied in the field of cargo box structure, can solve problems such as limited top space, difficulty in lifting and transporting cargo, large manpower, etc., and achieve the effect of wasting labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

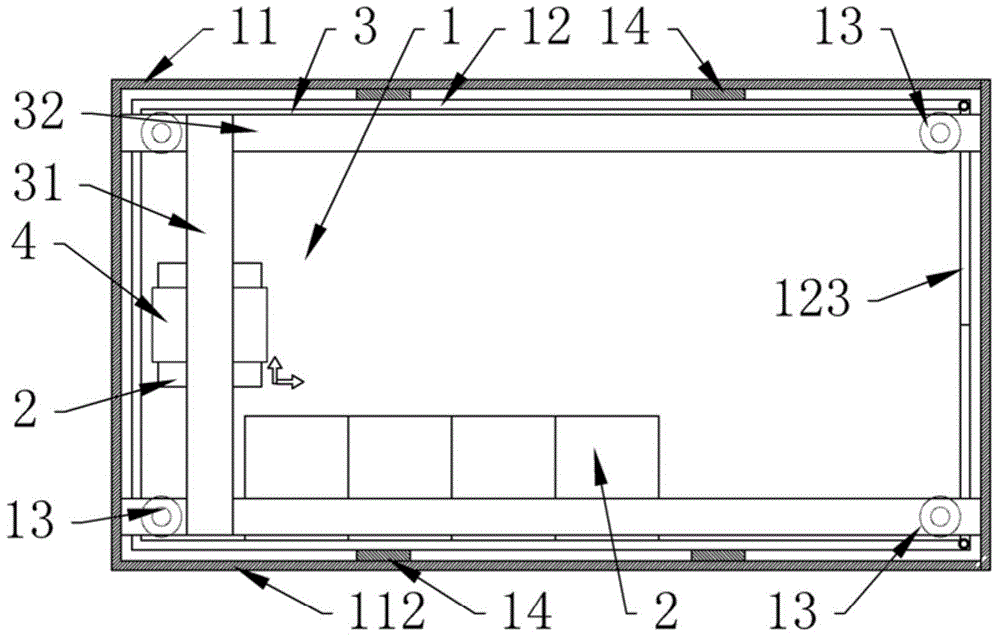

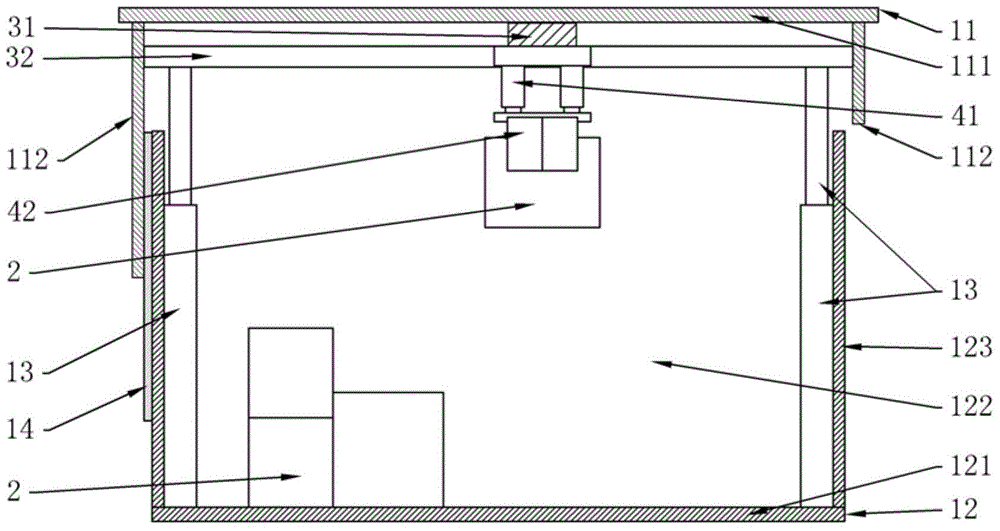

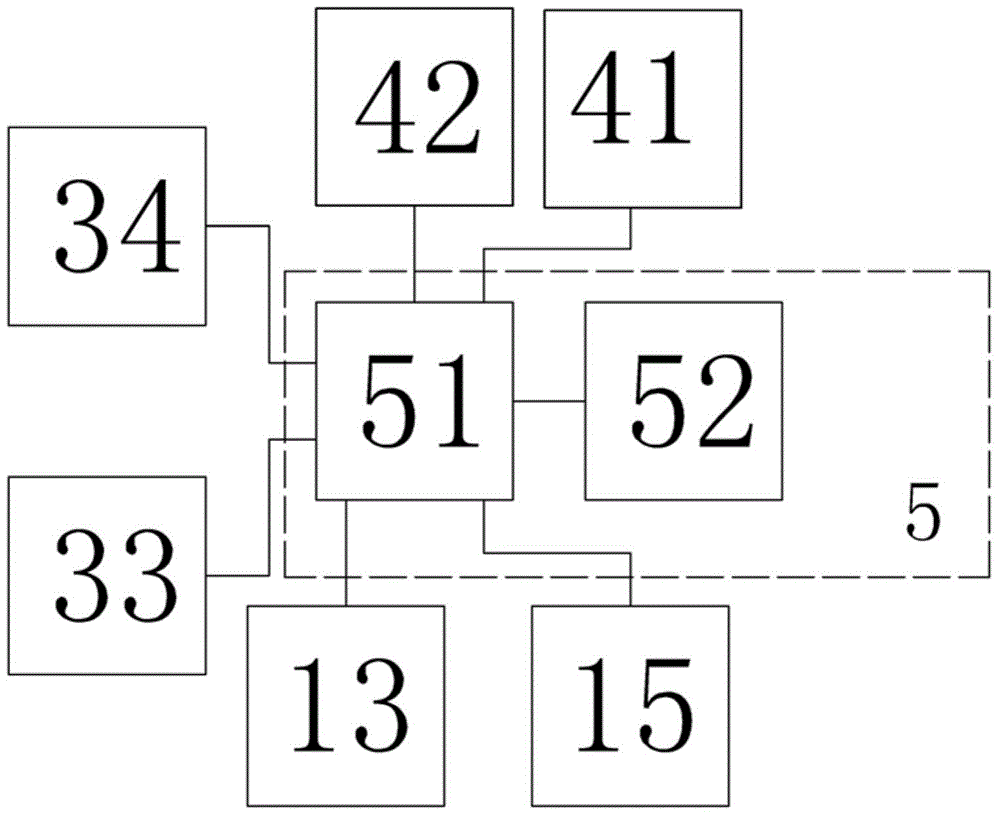

[0030] see Figure 1-6 As shown, Embodiment 1 of the present invention provides a cargo box structure capable of intelligent loading and unloading of goods, which is used for accessing the hoisted objects 2 in the cargo box 1 . The cargo box 1 is composed of an outer box body 11 with an open bottom and an inner box body 12 with an open top, and the outer box body 11 is sleeved on the inner box body 12 . Wherein: the inner box body 12 comprises a bottom wall 121, three inner side walls 122 and two compartment doors 123, the three inner side walls 122 are fixed on the outer edge of the bottom wall 121, and the compartment door 123 is hinged on the inner side walls 122 The outer box body 11 includes a top wall 111 and four outer side walls 112, and the four outer side walls 112 are fixed and suspended around the top wall 111. The four corners of the bottom wall 121 are provided with jacking devices 13 respectively, and in this embodiment, the jacking devices 13 are hydraulic jac...

Embodiment 2

[0042] see Figure 7-8 As shown, the main difference between Embodiment 2 and Embodiment 1 is that the lifting assembly is an electric sling lifting assembly, including a wire rope 411 , a winding wheel 412 and a fixed pulley 413 . The winding wheel 412 is driven by the winding motor 414 , and the wire rope 411 is wound by the winding wheel 412 and walks around the fixed pulley 413 . The fixed pulley 412 is fixedly located directly below the joint between the lifting mechanism 41 and the crossbeam 31, that is, just below the roller 43, so that the center of gravity falls on its suspension when the lifting mechanism 4 lifts the goods.

[0043] The top center of the hanging pan 421 of the grabbing assembly 42 is fixedly connected to the end of the wire rope 411 . Of course, it is also possible to directly connect a manipulator to the lower end of the wire rope 411, and such a structure usually completes the grabbing of small-volume goods. The sling lift assembly can also use a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap