Roadway rail type double-stand-column bidirectional stacking machine and using method thereof

The technology of roadway track and double column is applied in the field of roadway track type double column bidirectional stacker. The effect of realizing automatic and intelligent warehouse management and increasing storage buffer time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to better understand the above technical solutions of the present invention, the technical solutions of the present invention are further described below with reference to the accompanying drawings and embodiments.

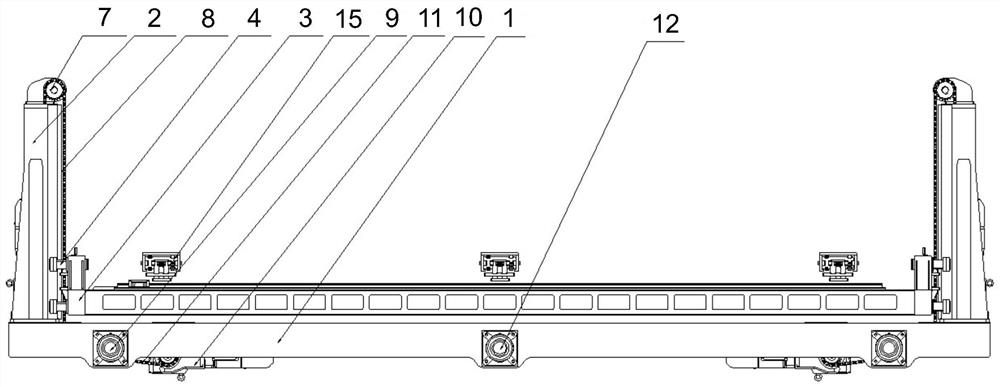

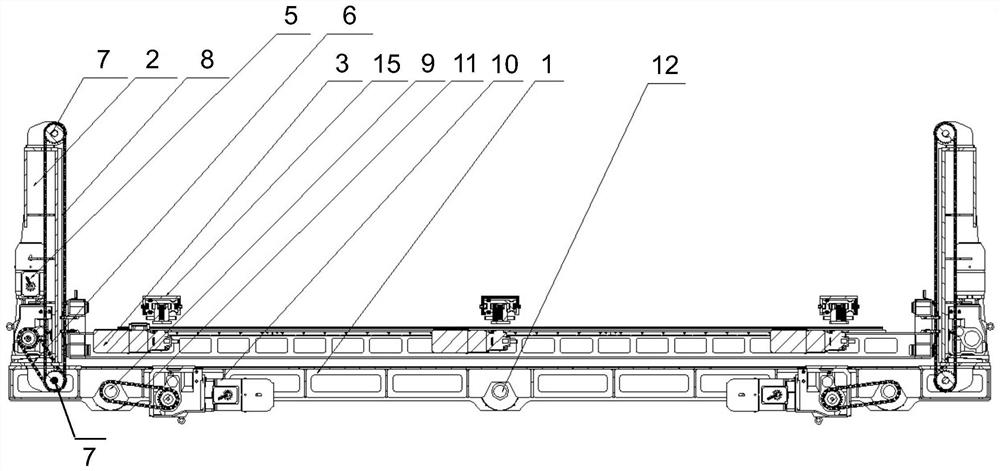

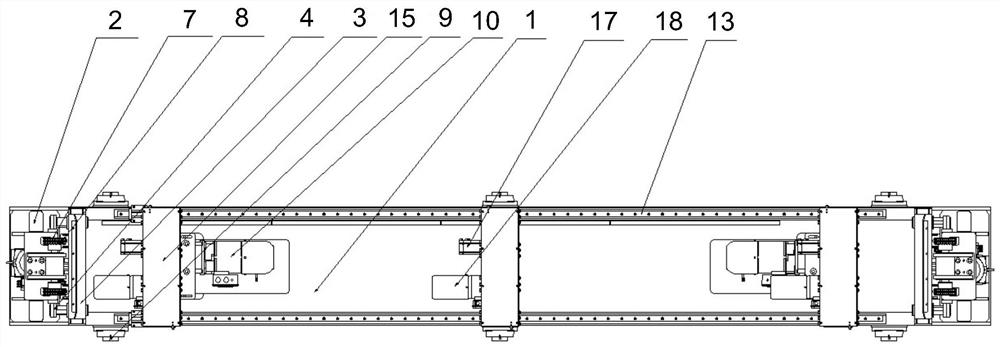

[0050] please combine Figure 1 to Figure 4 As shown, the present invention provides a roadway track-type dual-column bidirectional stacker, including a frame 1, a column 2, a movable table 3, a lift drive mechanism, a travel drive mechanism, a fork mechanism and a control system.

[0051] The frame 1 is arranged horizontally and is set as a rectangular frame structure.

[0052] There are two uprights 2, which are respectively installed and fixed at both ends of the frame 1 in the length direction. The structural design of the double uprights 2 without crossbeams is convenient for driving to access the steel plates stored on the roadway track-type dual-column bidirectional stacker of the present invention. Operation.

[0053] There are two sets o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com