Automatic storage system and access method of friction roller

A technology for storage and friction rollers, applied in general control systems, control/regulation systems, storage devices, etc., can solve problems such as slow speed, complicated access process, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

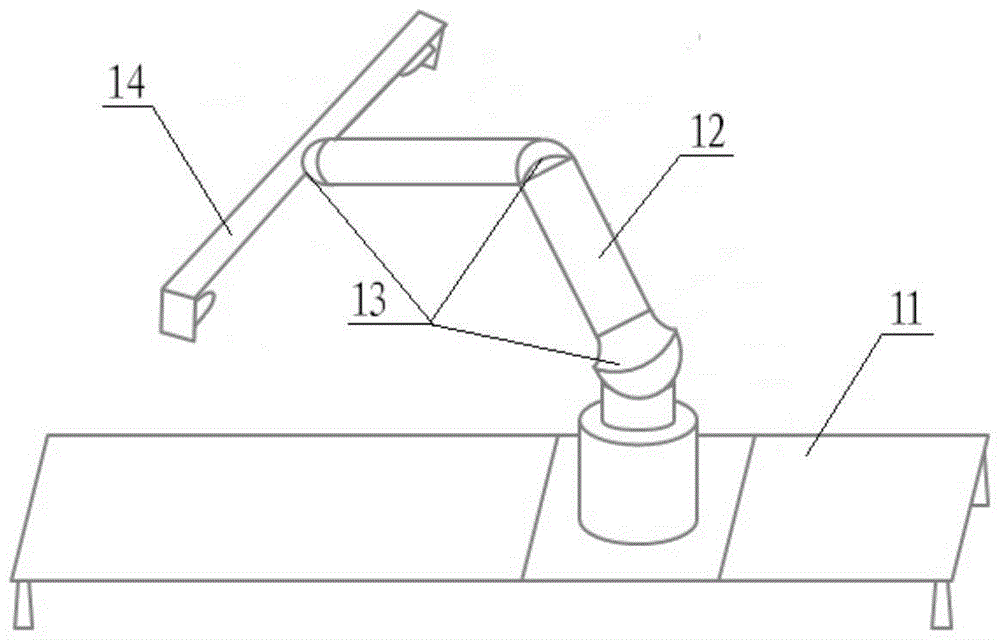

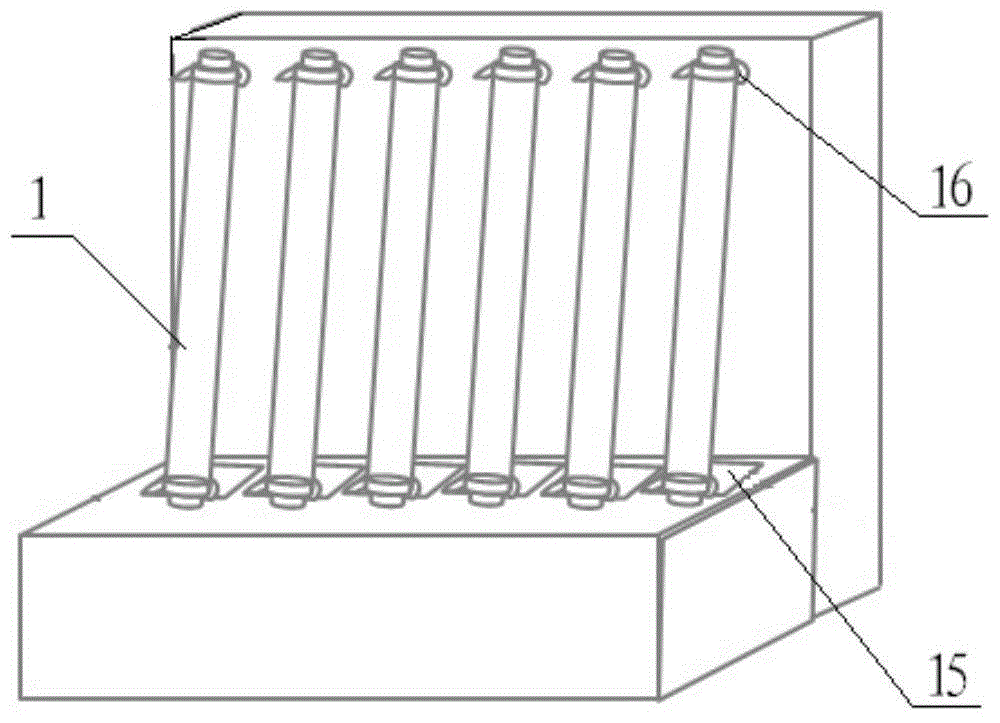

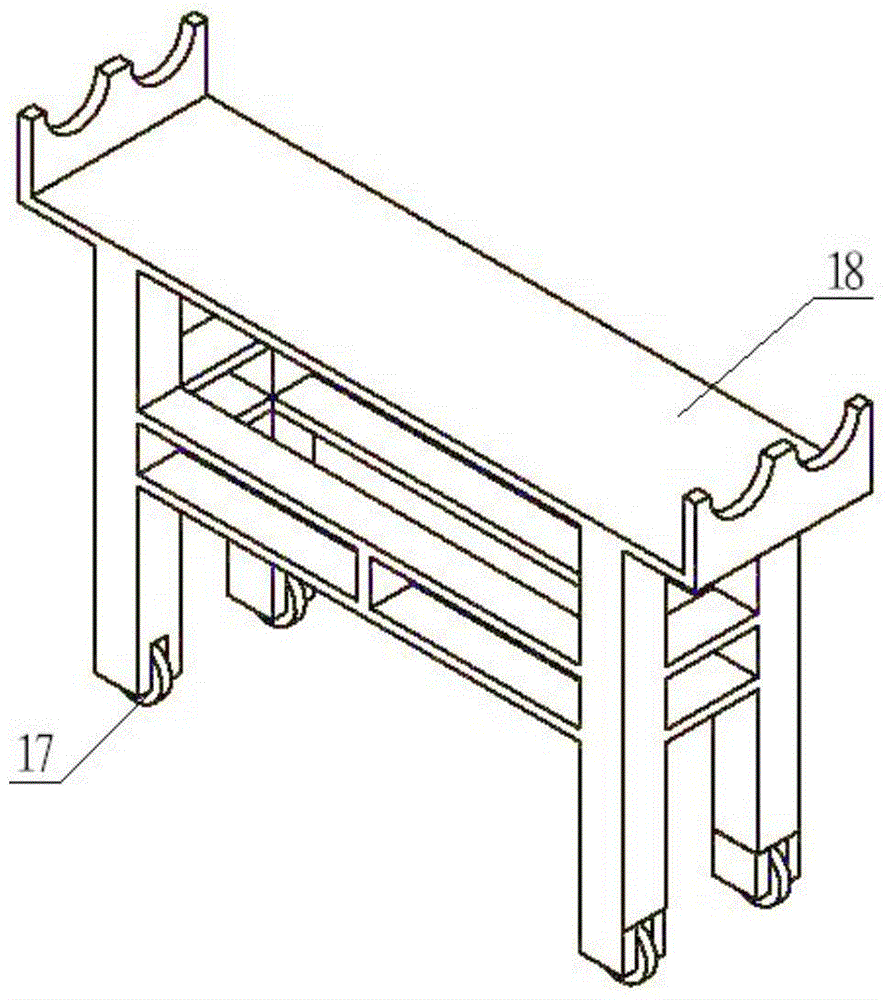

[0057] This embodiment is an automatic storage system for friction rollers, comprising a roller storage device 2, a roller transport track 3, a roller transport platform 4 and a positioning device 5, such as Figure 4-Figure 7 shown.

[0058] The roller storage device 2 includes a rotatable storage roller main body 20, such as Figure 6 and 7 As shown, one end of the storage roller body 20 is connected to the first bracket 201, and the other end is connected to the second bracket 205. The first bracket 201 and the second bracket 205 are fixedly installed on both sides of the roller track 3, and the first bracket 201 is provided with The first motor 202 capable of driving the rotation of the storage roller main body 20; in addition, one end of the storage roller main body 20 is provided with at least two first clamping members 213 uniformly distributed in the circumferential direction, and the other end of the storage roller main body 20 is provided with the first The clampin...

Embodiment 2

[0075] This embodiment is an automatic deposit and retrieval method for the friction roller by using the automatic storage system for the friction roller in the first embodiment above. The automatic roller storage operation process includes in sequence: fetching the roller, transporting the roller and storing the roller.

[0076] Roll taking: the control unit sends instructions to the transmission device (roller motor 406) between the roller platform 4 and the roller track 3, and the transmission device (roller motor 406) will drive the roller platform 4 to move along the roller track 3 to At the corresponding position of the friction machine device 6, the transmission device obtains an instruction to stop the transmission; subsequently, the first lifting device (for example, the above-mentioned cylinder 407) will drive the roller table 402 to move upward to a certain height after obtaining the instruction issued by the control unit; then , the automatic roller unloading device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com