Three-portal-frame material taking machine

A technology of reclaimer and tripod, applied in the direction of lifting device, etc., can solve the problems of increasing cost, increasing size, limited lifting height of reclaimer, etc., and achieve the effect of improving safety and lifting safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

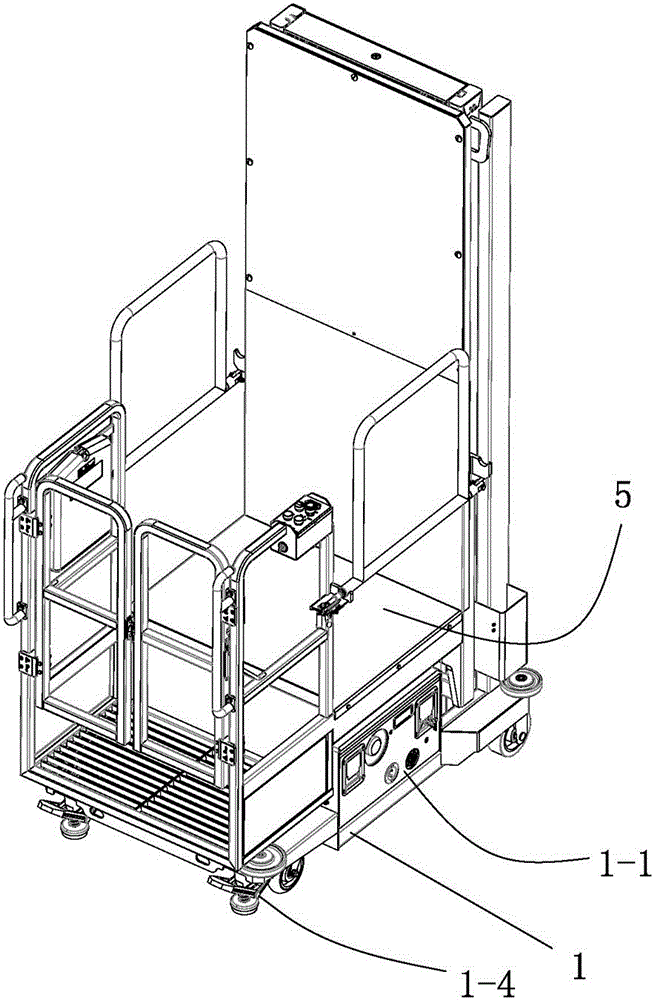

[0053] A three-door reclaimer has a chassis 1, a lifting structure and a reclaiming platform 5. The overall structure is as figure 1 As shown, there are wheels at the bottom of the chassis 1, which do not have the ability to actively rotate, so that the whole machine needs external force to move. Brake feet 1-4 are arranged next to the front wheel. When the brake feet 1-4 are stepped on, the brake feet 1-4 can be offset against the carrier surface of the reclaimer, so that the reclaimer has at least part of the gravity. It is assigned to brake top feet 1-4 to generate static friction to achieve positioning.

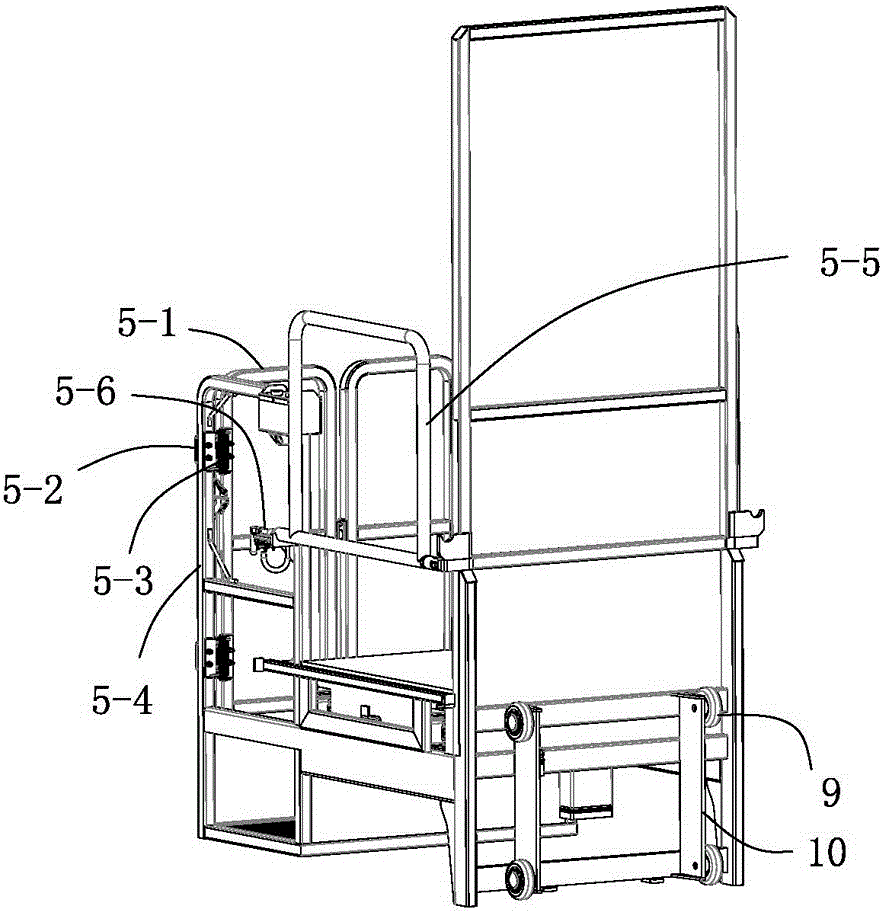

[0054] like figure 2 Shown is the structural diagram of the reclaiming platform 5 of the reclaimer. The material reclaiming platform 5 has a split double front door 5-1 and a scissor type side door 5-5, and the double front door 5-1 is installed on the material reclaiming platform through a limit block 5-2 and a torsion spring 5-3 5 on the frame 5-4, the front door 5...

Embodiment 2

[0064] A reclaimer, which has a chassis 1, a lifting structure and a reclaiming platform 5. The overall structure is as Figure 11 As shown, it is basically the same as Embodiment 1, the difference is that it is self-driven, such as Figure 4 As shown, it is driven by two rear active directional wheels 1-3, and is driven non-coaxially, each driven by an independent motor. Therefore, the forward, backward and turning directions of the reclaimer are all determined by the rotational direction and / or rotational speed difference of the two rear active orientation wheels 1-3. For example, when the direction of rotation and the rotational speed difference of the two rear active orientation wheels 1-3 are consistent, the reclaimer moves forward in a straight line or retreats in a straight line; if they all rotate forward, the rotation speed of the left wheel is greater than that of the right wheel. Then the reclaimer turns right while advancing.

[0065] The difference is also that...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap