Base plate cutting machine and base plate long edge cutting and splitting method

A cutting machine and cutting mechanism technology, applied in glass cutting devices, glass manufacturing equipment, glass production, etc., can solve the problems of increased takt time and reduced production efficiency, and achieve the goal of reducing takt time, improving production efficiency, and reducing waiting time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

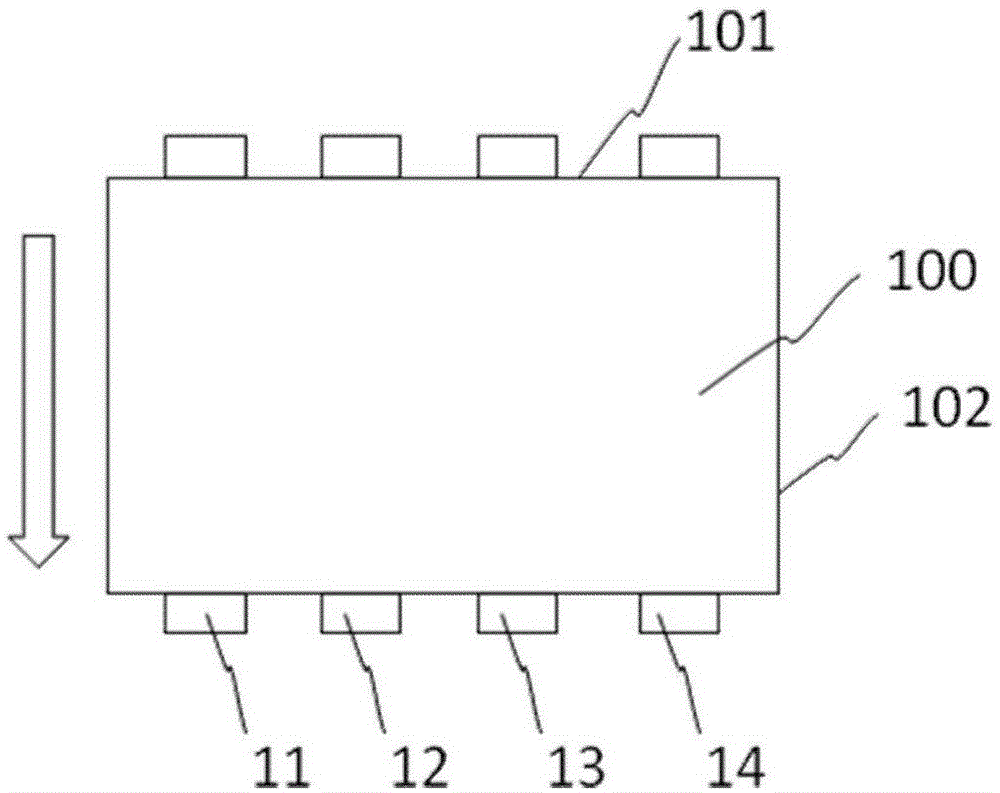

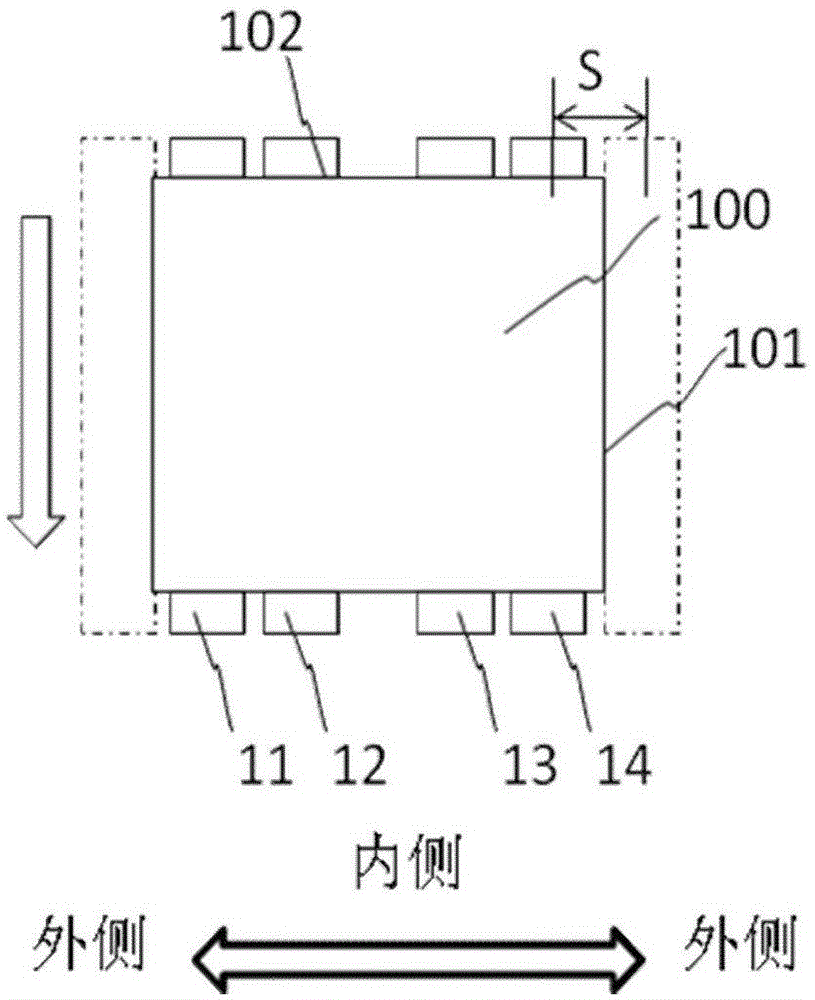

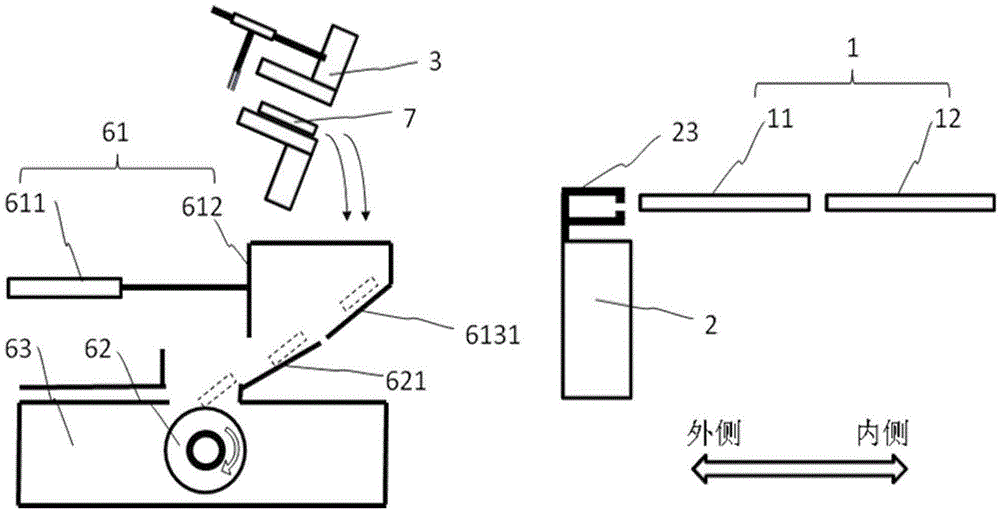

[0037] Embodiment 1 of the present invention provides a substrate cutting machine, such as Figure 3-5 , mainly including: a substrate carrying platform 1, which is divided into four pieces, namely a platform 11, a platform 12, a platform 13 and a platform 14, wherein the platform 11 is symmetrical to the platform 14, and the platform 12 is symmetrical to the platform 13, and its function is to carry the glass substrate; The cutting mechanism 2 includes a cutter wheel mechanism, which is used to cut and mark the substrate to facilitate the subsequent splitting process, and a substrate clip mechanism 23 located above the cutter wheel mechanism, whose function is to carry the substrate; the split mechanism 3, whose function is to carry out The lobes separate CF residual material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com