Efficient pile driver tower and pile driving method

A piling frame and high-efficiency technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of difficult transposition and reduced construction efficiency, and achieve the effect of reducing the weight of the whole machine, reducing the transportation cost and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

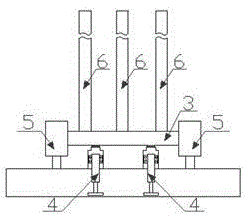

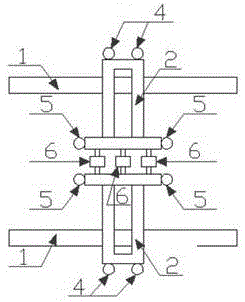

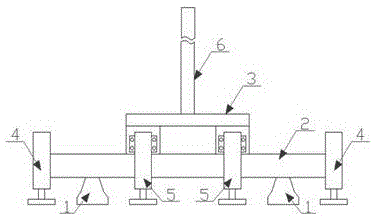

[0026] see Figure 1-3 , the invention discloses a high-efficiency piling frame. As shown in the figure: it includes two front and rear moving guide rails 1 arranged in parallel and kept at a certain distance. Front and rear moving guide rail 1 can be designed as box-type guide rail, also can be designed as tubular. Install the front and rear moving beam 2 on the front and rear moving guide rail 1; Always keep the same distance in the vertical direction, that is, a certain structure (such as sliding mosaic structure, sliding nesting structure, etc.) Always keep consistent in the vertical direction, that is to say, the front and rear moving guide rails 1 are also lifted together when the front and rear moving beams 2 are lifted. The left and right moving beam 3 is installed on the front and rear moving beam 2; the left and right moving beam 3 can move left and right along the front and rear moving beam 2 under the action of the driving force, and the vertical direction betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com